to protect finished surfaces from damage. Raise the

housing and rest it on two blocks as shown in Fig-

ure 2-2. Once the housing is vertical, remove nuts

holding the long vertical skids. Pull the skids from

the bolts, then take off the two cross timbers. Place

housing over the foundation bolts on top of shims.

Place flat washers on each foundation bolt and

start nut on bolts. To ease later assembly of bed,

plumb housing front and side. This can be checked

with the level in squaring head of an ordinary

machinists' square or with any square that can be

used on a vertical surface. Use flat steel shims

under the housing feet as required to plumb both

surfaces. Tighten the foundation bolt nuts with

wrench. Remove lifting device.

Erect the other housing using the same procedure

as for the first housing. Place a flat washer on each

foundation bolt and start nut on bolts. Do not tight-

en nuts. Shim housing to obtain plumb in relation

to first housing and distance between housings.

Carefully check distance between housings. This is

measured from inside finished surface where bed is

attached.

Example: For a 600FM x 12'. This measurement is

12'-6". The measurement can be taken

from the machined slots in rear of bed.

Tighten foundation bolt nuts with wrench. Align

both housings as shown in Figure 2-4 by shifting

housings as required.

Machines with Auto Crown: The rear deflection

plate should be placed in the foundation pit at its

approximate location before the bed is installed.

Remove bed shoes and bed bolts from shipping box.

Clean bearing surfaces of housings and matching

bed slot surfaces, and the bed shoes and bolts.

Carefully lubricate all finished surfaces of housings

where the bed fits. Also lubricate top and bottom

surfaces of bed shoes. Use EP #2 lithium grease (C.

I. grease H-2EP). Place bed shoes into position on

the housings. Match the markings on housings and

bed shoes. Place bed into position on the housings.

Insert bed bolts into bed. Loosen all foundation bolt

nuts and tighten bed bolts securely. Retighten

foundation bolt nuts securely. See chart (Figure 2-

3) for bed bolt and foundation nut seating torques.

Check your work with feeler gages. There should be

no clearance between vertical bearing surfaces of

the housings and bed. If there is clearance, either

the bed bolts are not tight or there is grit between

bearing surfaces. There should be no clearance

between bed shoes and the bed. If there is clear-

ance, remove the bed.

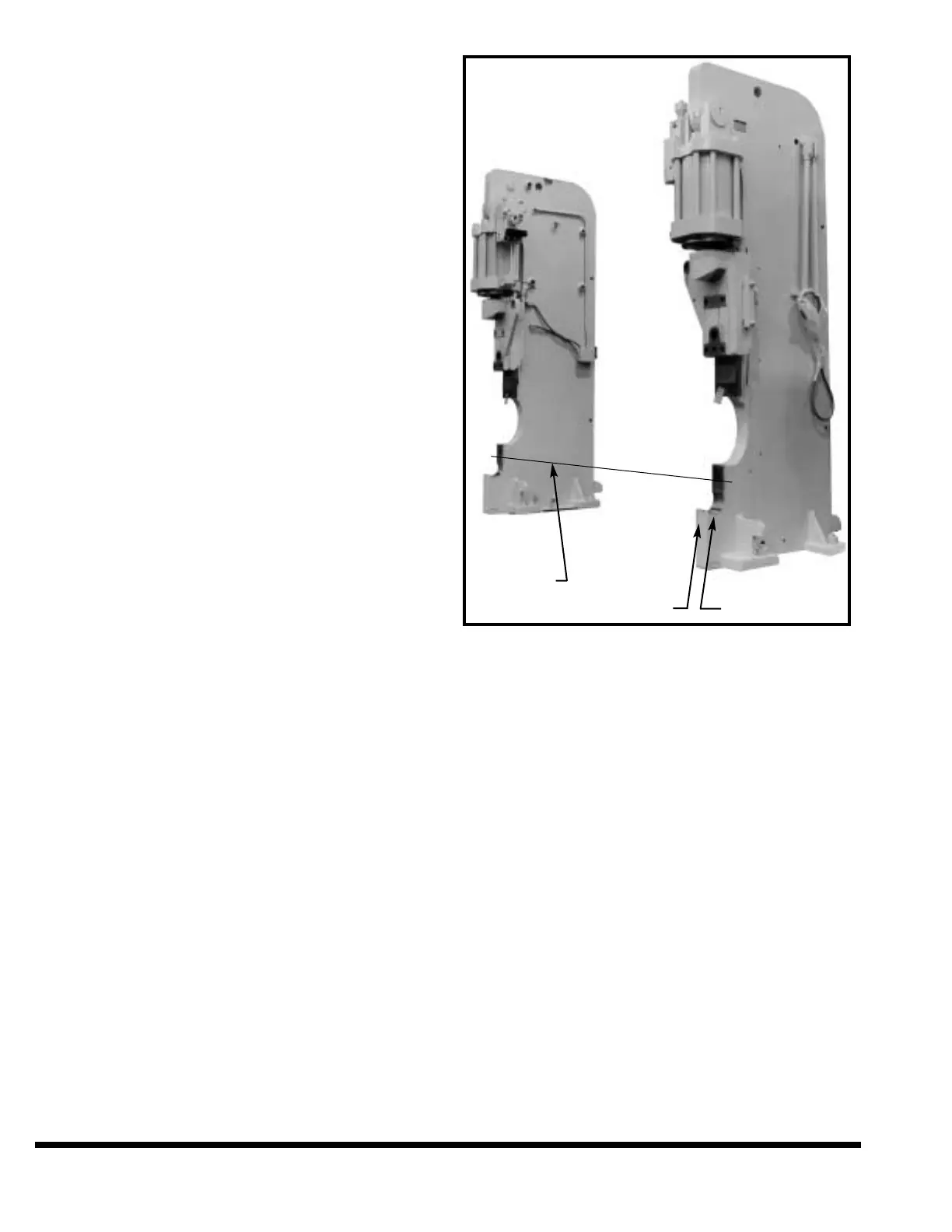

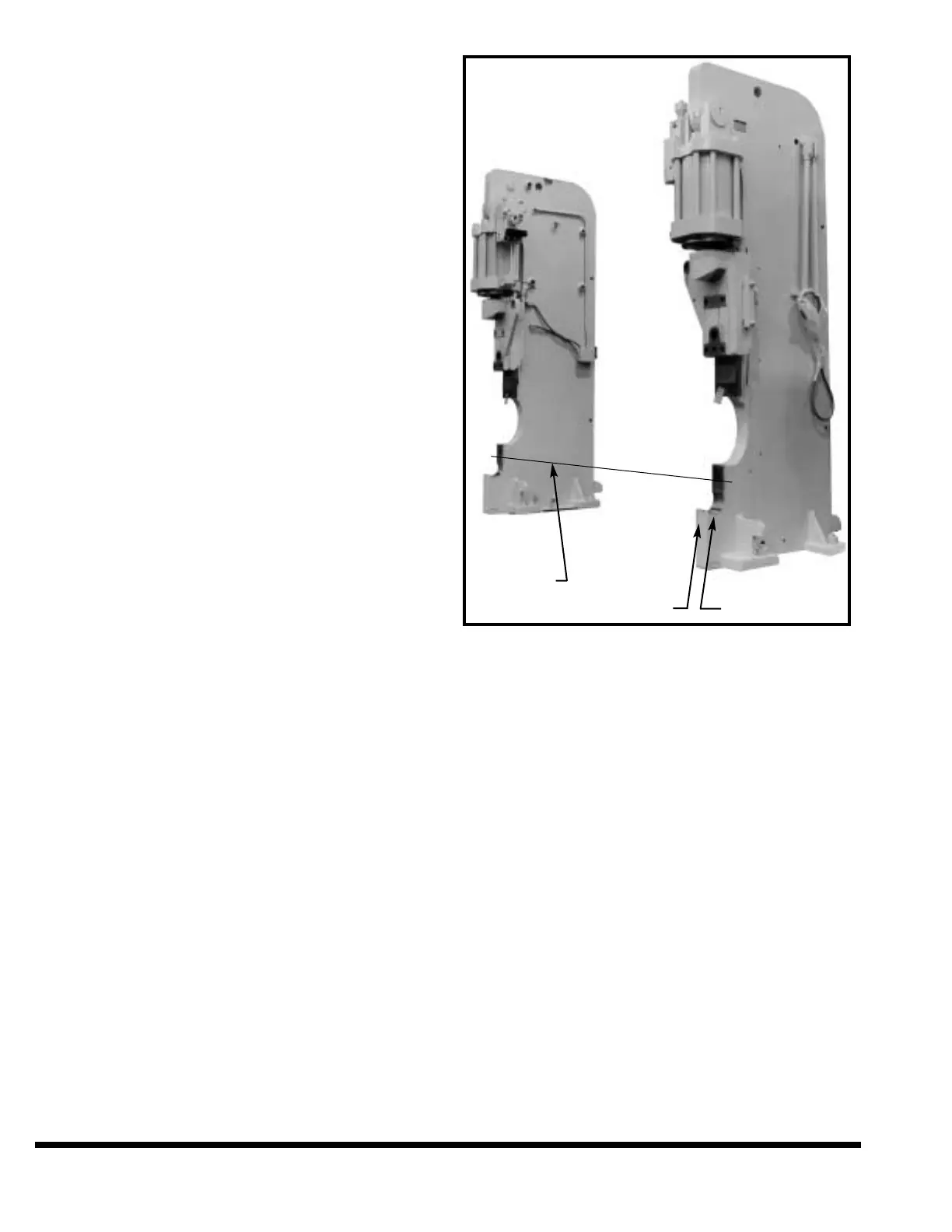

FIGURE 2-4 – Aligning housings

Determine and correct the cause of clearance.

Replace the bed as previously described. Recheck

clearance.

Tighten the lock-down screws between the hous-

ings and bed. They are located at the bottom of

each housing where housing fits bed.

CINCINNATI Hydraulic Press Brakes are leveled by

placing flat steel shims of proper thickness under

the housing feet as required. Use a precision level

graduated in .0005" per foot – not a carpenter's or

machinist's level. Always wipe level and bed surface

clean before placing the level.

The 400FM machines can be raised or lowered by

using leveling screws in the housing feet. Use at

least a two foot length of pipe on the wrench. On

larger machines jack lugs on sides and back of the

housings are used for this purpose. The foundation

bolt nuts must be loosened, not removed, before

jacking the press brake. Before checking the level of

the machine the foundation bolt nuts must be

securely tightened.

2-4

ALIGN

THESE

SURFACES

MARKING HOUSING SEAT

Loading...

Loading...