CHECKING & SETTING HYDRAULIC

PRESSURES

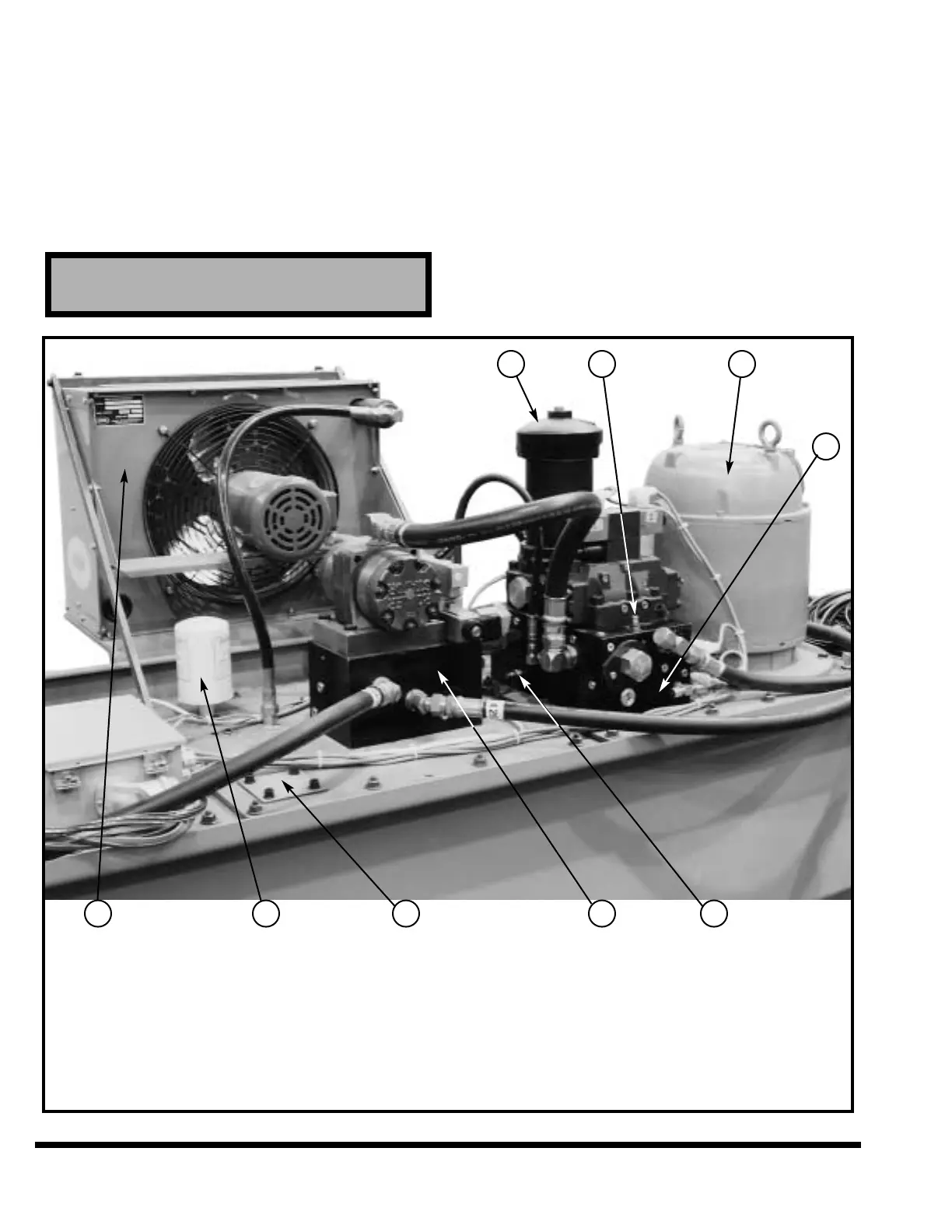

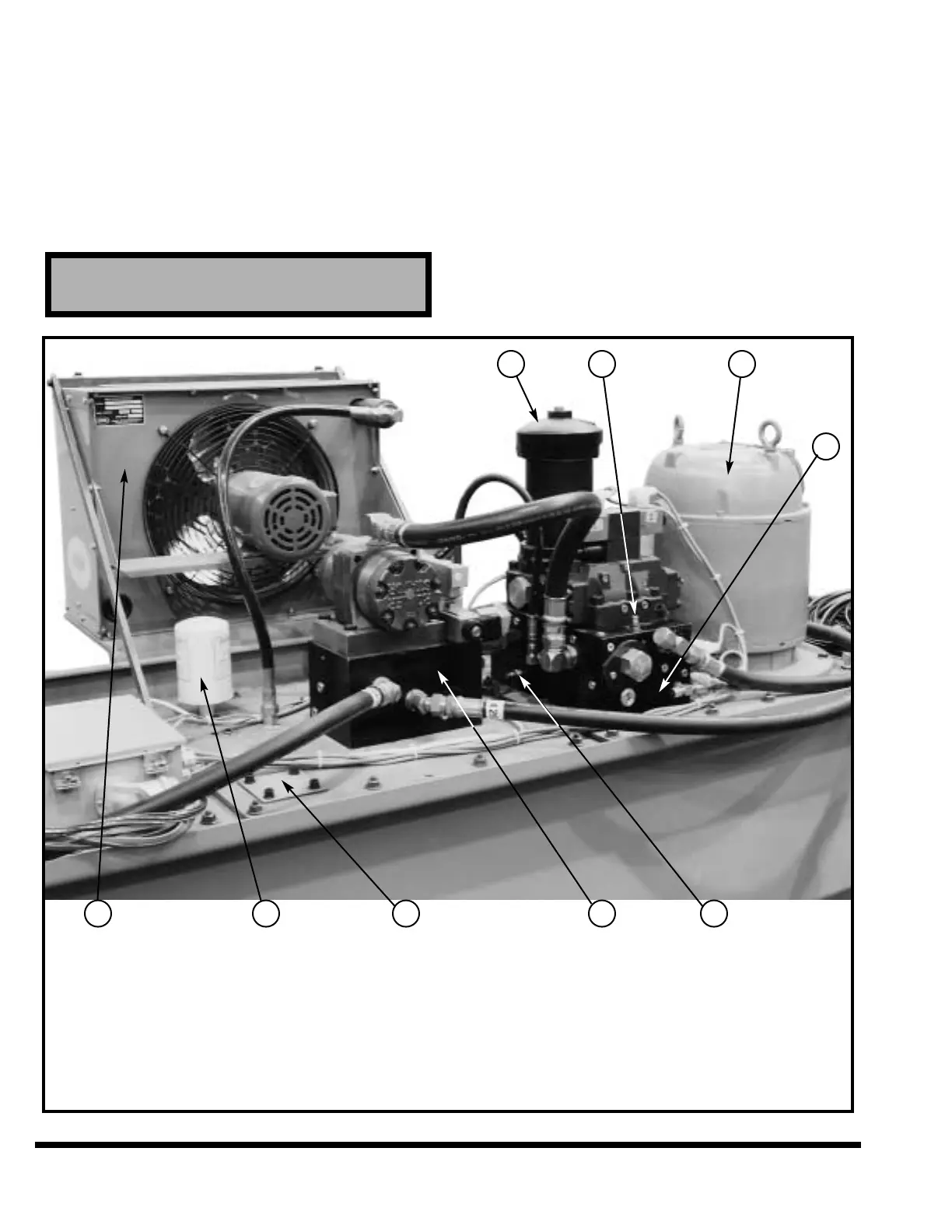

The hydraulic system is equipped with male

quick-disconnect fittings at the most frequently

checked pressure test ports. Identification of the

hydraulic system components is shown on Figure

9-5A and 9-5B, 9-6A and 9-6B and 9-7.

COUNTERBALANCE PRESSURE

Two test ports (#3) are provided in the circuit for

checking counterbalance pressure. See Figure 9-7.

No dies should be installed in the machine during

this check.

1. Set the machine controls:

OPERATOR STATION RIGHT ON

FOOTSWITCH OFF

MODE SELECT SET-UP

OPERATOR CONTROLS Selector ON

SUPERVISOR Selector ON

2. Start machine by turning main disconnect ON

and pressing MAIN DRIVE “START” button.

CAUTION

All dies must be removed from the press brake.

9-4

9 5

1 2 3

4

678

1. HIGH PRESSURE FILTER

2. TEST PORT #5

3. MOTOR / PUMP

4. MAIN MANIFOLD

#1 SOLENOID - DOWN VALVE

#2 SOLENOID - UP VALVE

#5 SOLENOID - PILOT VALVE

#6 SOLENOID - SAFETY DUMP VALVE

MAIN RELIEF VALVE

MANUAL MANIFOLD BLEED VALVE

5. TEST PORT #4

6. FLOW DIVIDER MANIFOLD

#7 SOLENOID - LEVELING VALVE

#8 SOLENOID - LEVELING VALVE

#9 SOLENOID - DECOMPRESSION VALVE

FLOW DIVIDER

PRESSURE TRANSDUCER

7. LOCATION FOR OPTIONAL OIL HEATER

8. AIR BREATHER / FILTER

9. AIR-COOLED HEAT EXCHANGER

FIGURE 9-6A – Hydraulic reservoir components (For 400 - 750 FM Standard)

Loading...

Loading...