3. Recheck that all dies are removed.

4. Use the Palmbutton Operator Station to cycle

the ram down and the “RAM UP” button to

cycle the ram upwards.

5. Move ram up using RAM UP button to top stop.

6. Install 0-1000 PSI range pressure gage with a

female quick-disconnect into either test port

#3. Both must be checked.

7. The counterbalance pressure is checked while

running the ram down in SET-UP. The proper

pressure can be determined by adding 100 PSI

to the pressure required to hold the ram up

while the motor/pump is turned off. If very

heavy upper dies are to be used in the machine,

consult CINCINNATI INCORPORATED for infor-

mation to set the counterbalance pressure.

8. To adjust the pressure, loosen the locknut and

turn adjustment screw on counterbalance

valve. Turn adjusting screw clockwise to

increase and counterclockwise to decrease

pressure. Tighten the locknut.

CAUTION

Do not run ram up with gage attached.

9-5

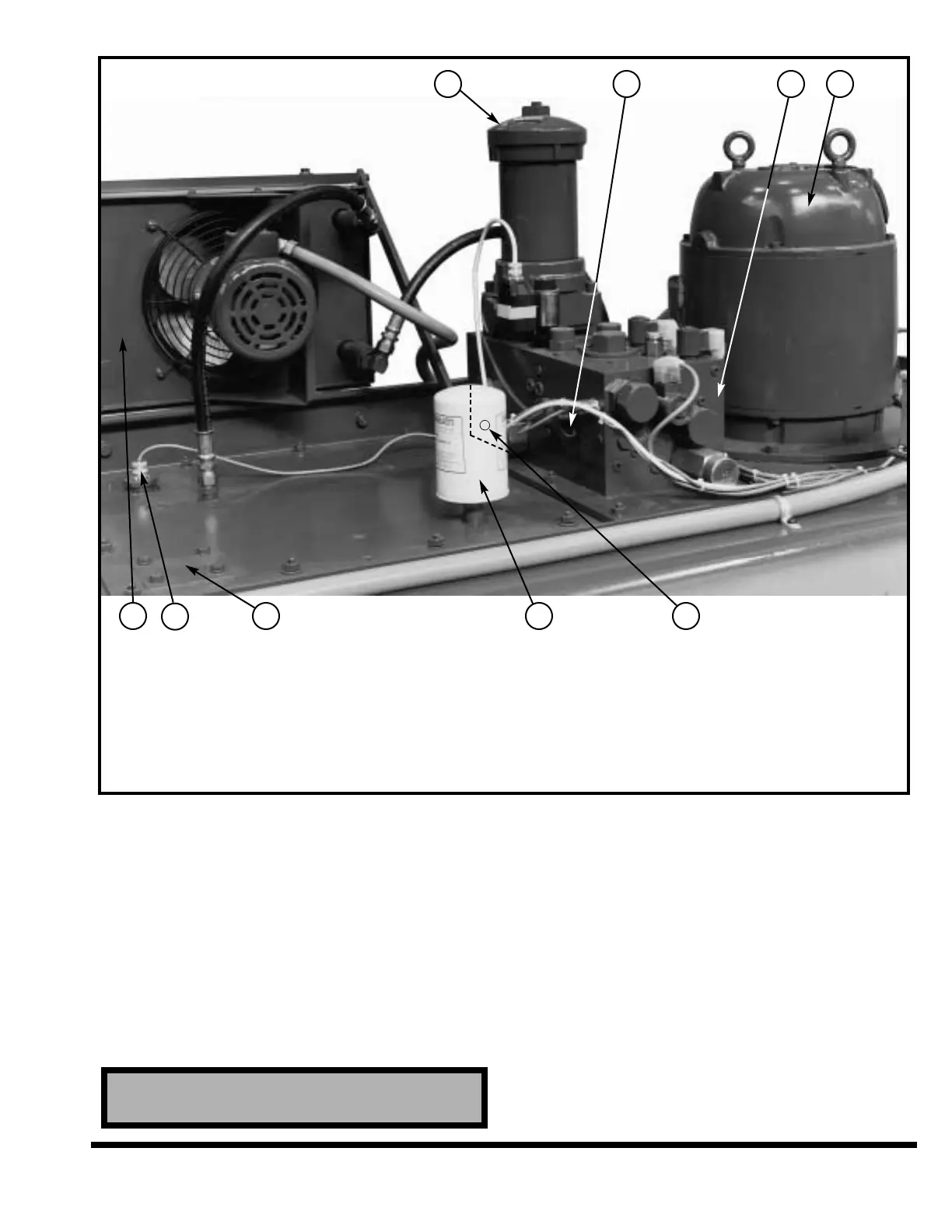

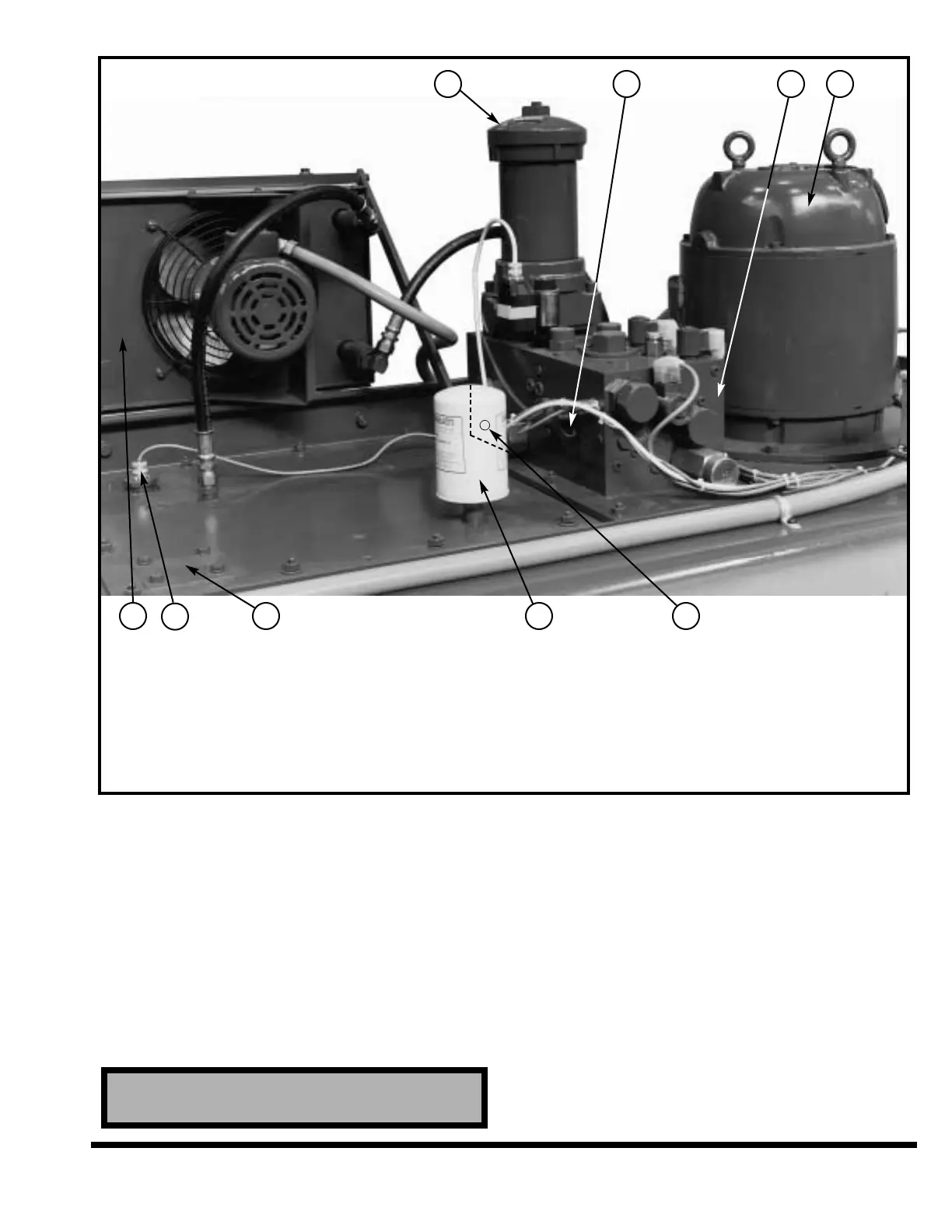

1. HIGH PRESSURE FILTER

2. TEST PORT #5

3. MAIN MANIFOLD

#1 SOLENOID - DOWN VALVE

#2 SOLENOID - UP VALVE

#5 SOLENOID - PILOT VALVE

#6 SOLENOID - SAFETY DUMP VALVE

VALVISTOR - SPEED & LEVEL CONTROL VALVE

#9 SOLENOID - DECOMPRESSION VALVE

PRESSURE TRANSDUCER

3. MAIN MANIFOLD (Continued)

MAIN RELIEF VALVE

MANUAL MANIFOLD BLEED VALVE

4. MOTOR / PUMP

5. TEST PORT #4 (Behind Air Breather / Filter)

6. AIR BREATHER / FILTER

7. LOCATION FOR OPTIONAL OIL HEATER

8. OIL LEVEL / TEMPERATURE SWITCH

9. AIR-COOLED HEAT EXCHANGER

FIGURE 9-6B – Hydraulic reservoir components (For Hydraulic Speed Package & 1000 - 2000 FM)

1 2 3 4

9

8

7 6 5

Loading...

Loading...