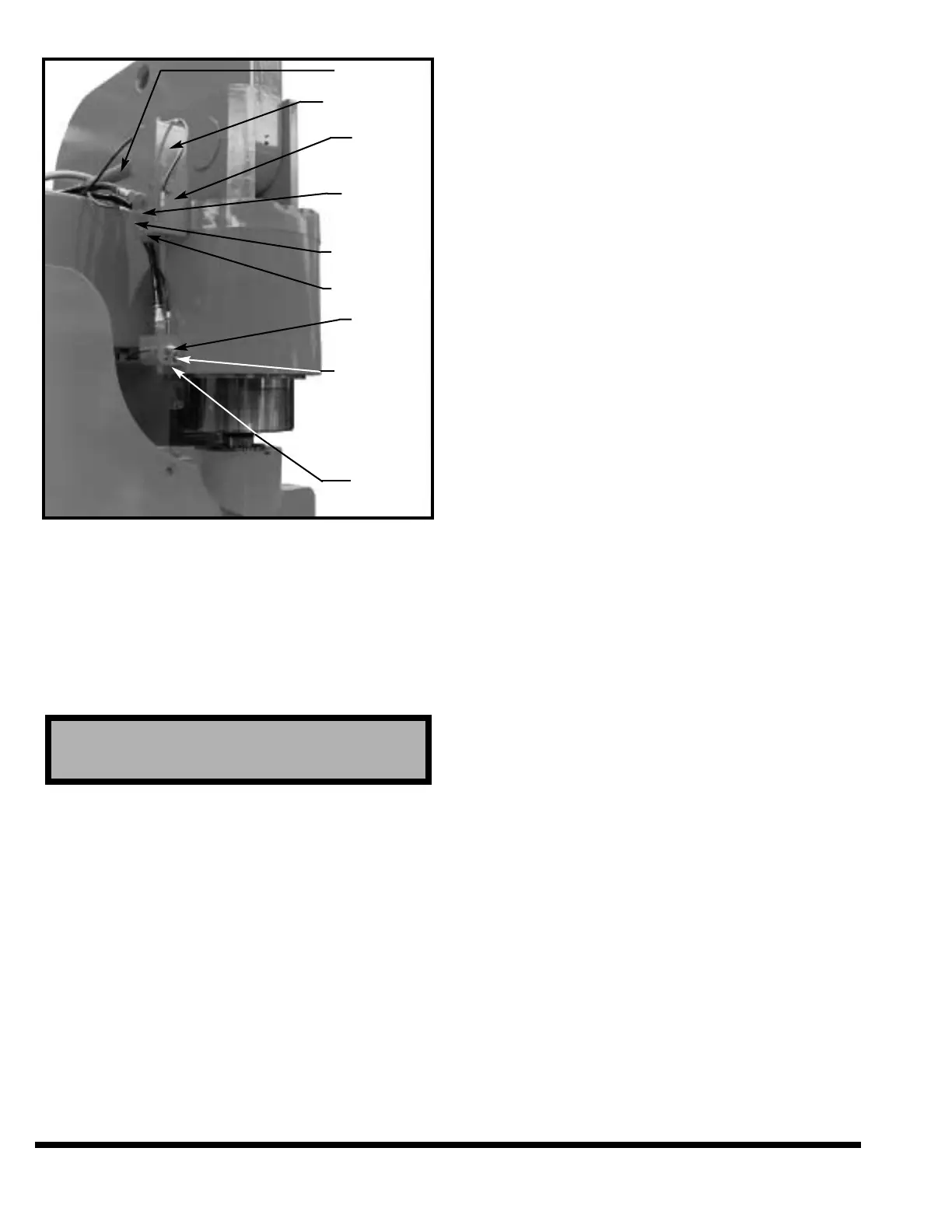

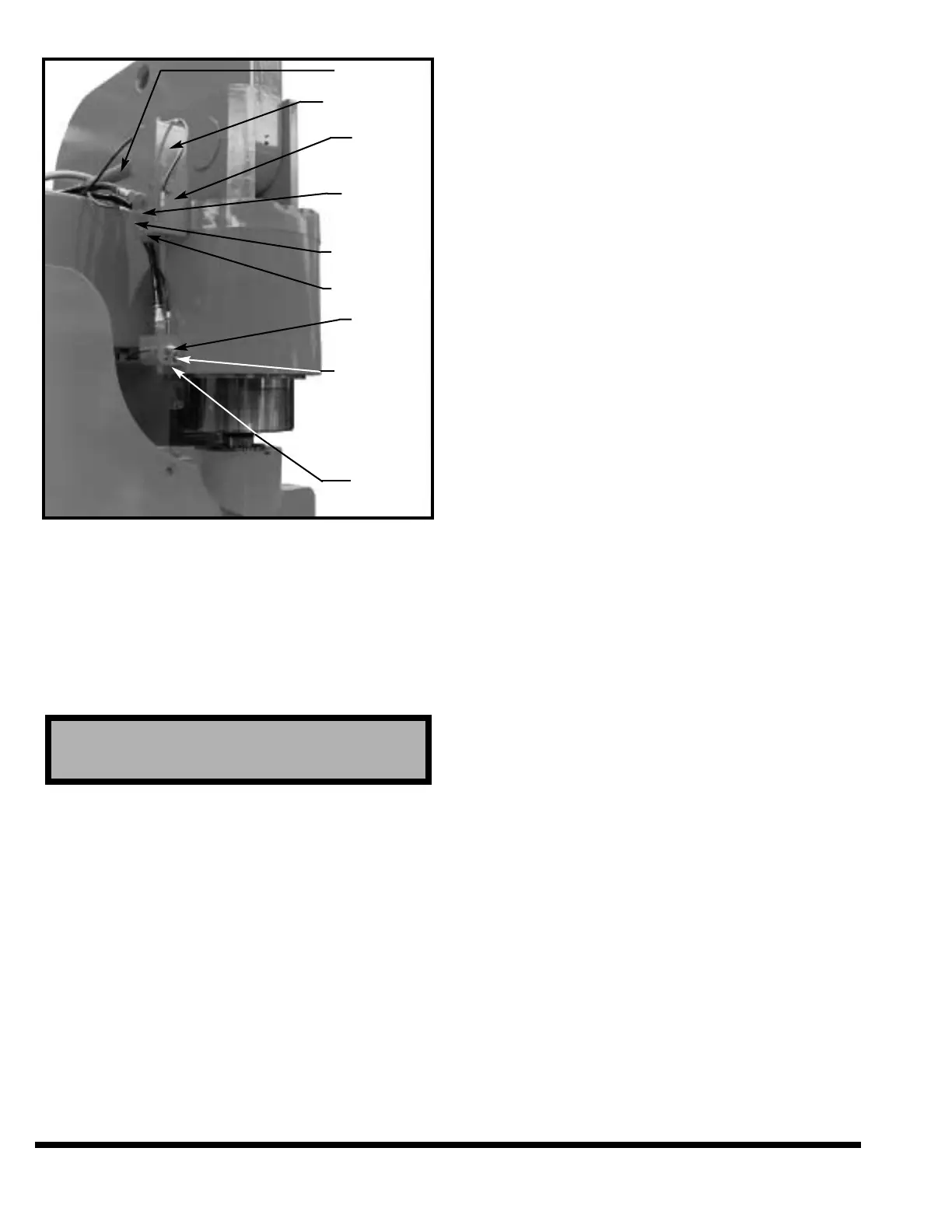

FIGURE 9-7 – Counterbalance pressure check

9. After setting the pressure, cycle the ram a

number of strokes and recheck both counter-

balance pressures. Remove gage before cycling

ram to up position.

10. Turn OFF motor/pump and remove pressure

gage.

MAIN RELIEF PRESSURE

This pressure is controlled by a preset valve and

cannot be adjusted. Contact a CINCINNATI

INCORPORATED Service Representative if this

pressure must be checked.

AIR FILTER / BREATHER

The air filter/breather is located on the auxiliary

cover plate. (See Figure 9-6A and 9-6B.) The dis-

posable, canister-type breather/filter should be

replaced about every 2000 hours of machine

operation.

OIL LEVEL / TEMPERATURE

SWITCH

If the oil drops to the minimum allowable level,

an error message will appear on the display and

will cause the main drive to shut down. The

cause for the low oil level should be found and

corrected. Fill reservoir to the proper level.

If the operating temperature reaches the maxi-

mum level, an error message will appear on the

display. Stop machine operation as soon as pos-

sible and locate the cause of the excessive heat. If

the oil temperature continues to climb and reach-

es 150° (66°C), the main drive will shut down.

OIL COOLER

The oil cooler is an air-type heat exchanger.

Depending on the tonnage and machine configura-

tion, there may be two (2) heat exchangers. The

heat exchanger is equipped with a thermostatically

controlled electric fan which is operable only when

the motor/pump is running. The thermostat is set

to start the heat exchanger motor at approximately

135°F (57°C) oil temperature. A furnace type air fil-

ter is installed between the fan and the core of the

exchanger. The filter should be changed as

required. See Figure 9-6A and 9-6B.

HYDRAULIC UNIT OPTIONS

OIL HEATERS (Optional)

Oil heaters are recommended for cold start-ups and

cold running conditions (see temperature chart in

“HYDRAULIC OIL” section). It is an immersion-type,

thermostatically controlled, and is used indepen-

dently of the motor drive. Depending on the

machine length and/or options, there may be two

(2) heaters.

CYLINDERS

Cylinders on the CINCINNATI FM Press Brake are

shown in Figure 9-8. The inner piston is attached

to the fixed upper cylinder head and does not move.

The outer piston is attached to the ram, moving in

the cylinder and in relation to the inner piston. For

information to replace piston rod seals, contact

CINCINNATI INCORPORATED Service Department.

CAUTION

Do not leave gage permanently attached to test port.

9-6

PREFILL PIPE

PREFILL VALVE

RIGHT

CYLINDER

MANIFOLD

PILOT

SWITCHING

VALVE

TEST PORT #2

TEST PORT #1

COUNTER-

BALANCE

VALVE

COUNTER-

BALANCE

MANIFOLD

BLEED VALVE

TEST PORT #3

(BEHIND

COUNTER-

BALANCE

MANIFOLD

Loading...

Loading...