STEP REPT (Step Repeat): This value repre-

sents the number of times the ram will be cycled

for this step using the same reversal values each

stroke before continuing with the next step. The

default value of 1 indicates the step is only exe-

cuted once. This function allows two or more

identical program steps to be combined into one.

A value of zero will allow gage movement without

cycling the ram. The value before the ‘/’ indi-

cates the number of strokes remaining to com-

plete the step. The value after the ‘/’ is the total

number of repeats programmed.

Valid Range: 0 - 99

Default Value: 1

The following (FLNG DIM, R-AXIS, BEND AL, GA.

PAUSE, RETR DIS) will only be visible if an optional

backgage is installed.

FLNG DIM (Flange Dimension) (Optional):

This value is the desired position of an optional

X-axis backgage. The Flange dimension is the

distance between the center of the upper die and

the standard gaging surface of the backgage.

This value can also be entered by using the man-

ual GAGE JOG to position the backgage then

using the TRN key to transfer the actual gage

position into this field. Softkeys will appear when

this is the highlighted field to allow the backgage

to be jogged in or out. If the gage has not been

calibrated a “Gage Cal” softkey will appear in

place of the Jog keys.

Valid Range: 0.000 - X Max Dimension

Entry Format: XX.XXX English or XXXX.XX

Metric

Default Value: X Max Dimension -1”.

Gage Jog Softkeys: These softkeys allow manual

positioning of the backgage. Pressing and releas-

ing the key will move the gage by a small incre-

ment. Holding down the “Jog” key will begin

moving the gage in slow speed. After a few sec-

onds the gage will move in high speed. Releasing

the key will stop the gage movement. “Jog In”

moves the gage towards the die. “Jog Out” moves

the gage away from the die.

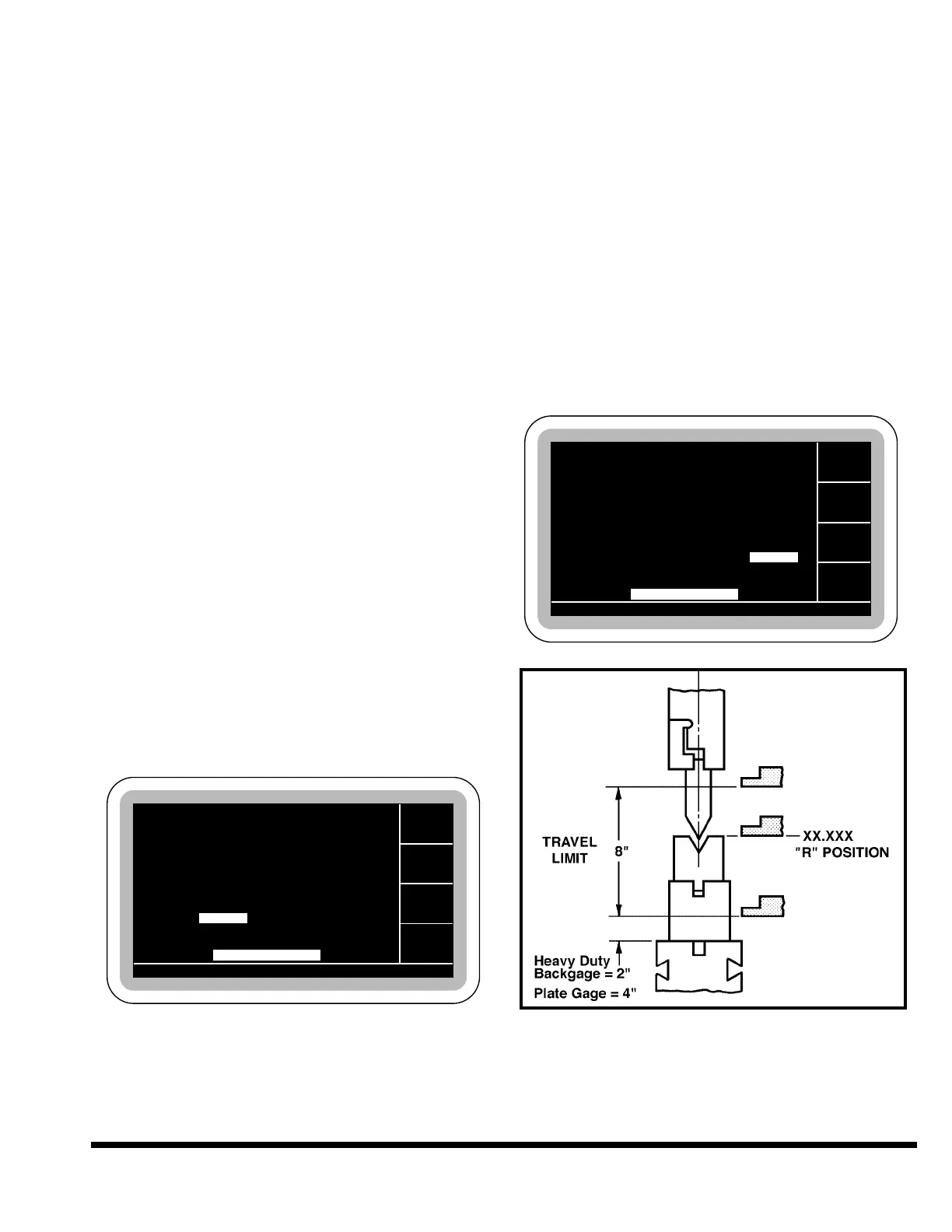

R-AXIS: This value is the desired position of an

optional programmable R-axis backgage. The

position is referenced to the bed. This value can

also be entered by using the manual GAGE JOG

to position the backgage then using the TRN key

to transfer the actual gage position into this

field. See Figure 7-4.

Valid Range: R Min. Dimension - R Max.

Dimension

Entry Format: XX.XXX English or XXX.XX

Metric

Default Value: R Max. Dimension

FIGURE 7-4 – R-Axis position

BEND AL (Bend Allowance): This value is

the allowance which is added to the actual

Flange Dimension value to determine the pro-

grammed gage position. If a bend allowance is

GA. PAUSE 0.1

GA. PAUSE 0.1

Loading...

Loading...