Note: Only one set of tool dimensions may be

used for a program. When ANGLE MODE

is ON, the DESIRED ANGLE, ACTUAL

ANGLE and REVERSAL values in the

PROGRAM DATA screen will be blanked

until the user enters a value.

MAT THICK (Material Thickness): This value

is entered once per program. If Angle Mode

reversal is not being used, this value is not

required.

Valid Range: 0.001” to 9.999” (0.03mm -

254.00mm)

Entry Format: X.XXX English or XXX.XX Metric

Default Value: 0.000”

If a value outside this Valid Range is entered the

field will display ????. If the operator advances to

the next field before entering a valid value, the

original value of the field is retained.

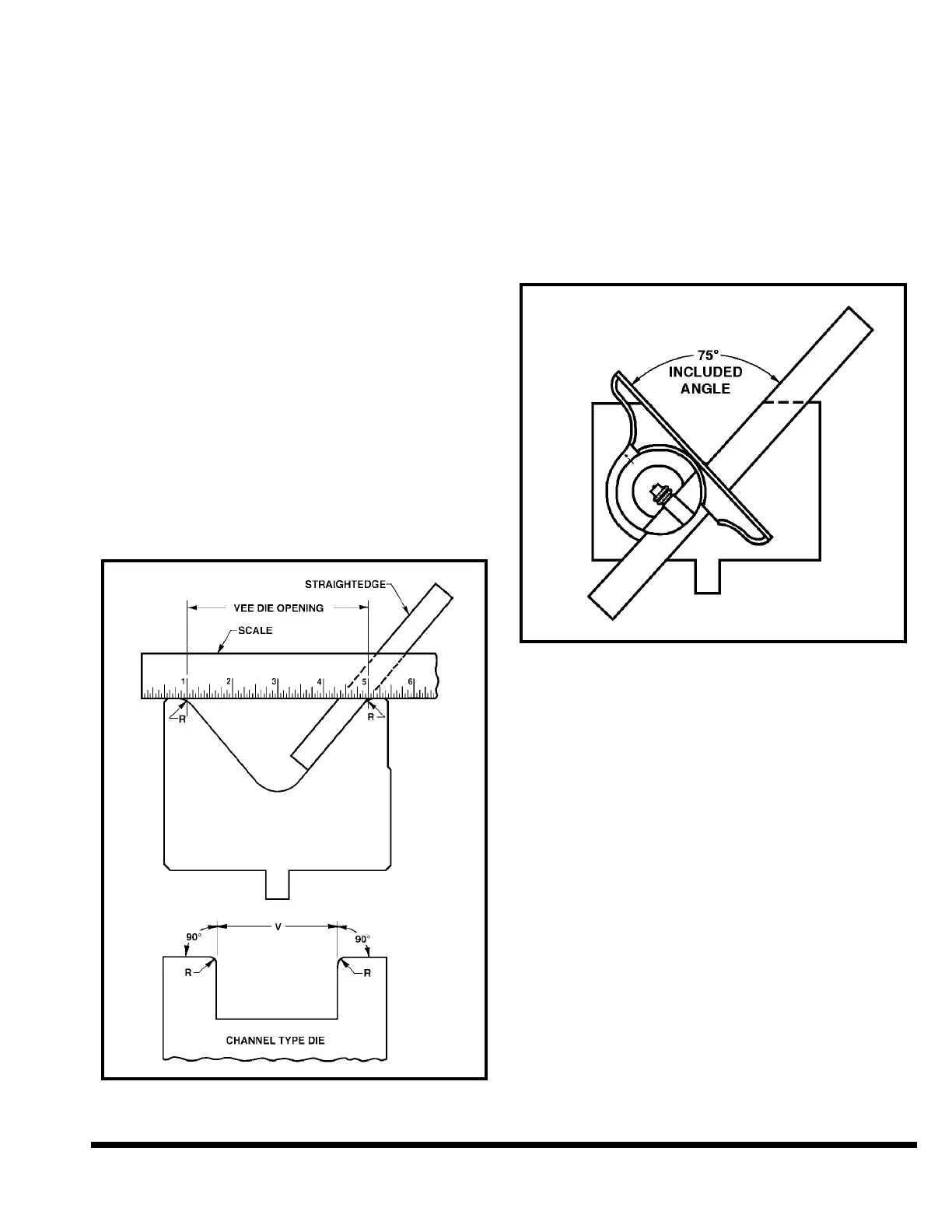

VEE OPENING: This value is entered once per

program. It represents the actual width of the vee

opening. If Angle Mode reversal is not being used,

this value is not required. Enter the dimension of

the Lower Tool Vee Opening. See Figure 7-1.

FIGURE 7-1 – Measuring the Vee Opening

Valid Range: 0.001” to 39.360” (0.03mm -

999.99mm)

Entry Format: XX.XXX English or XXX.XX

Metric

Default Value: 0.000

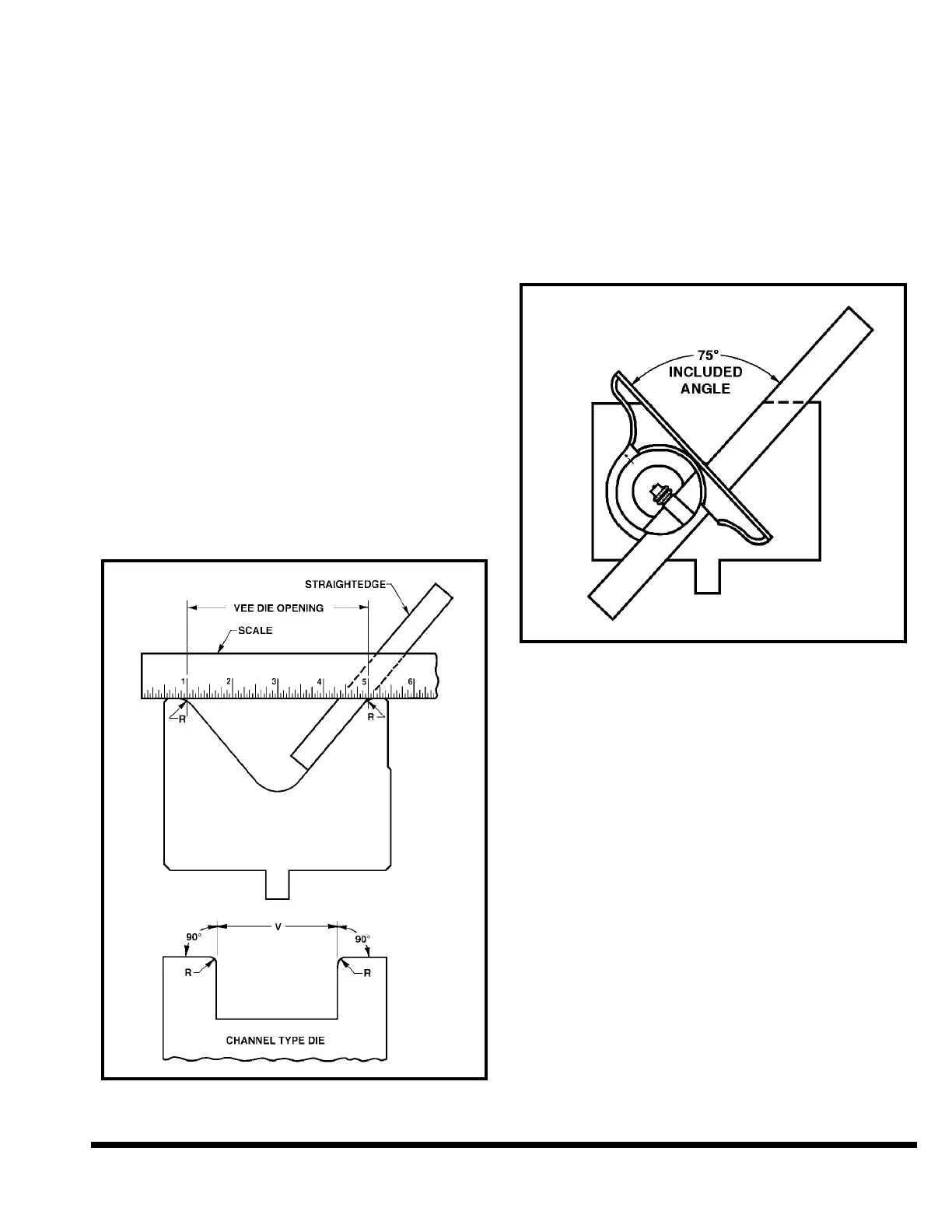

LOWER DIE ANGLE: This value is entered

once per program. If Angle Mode reversal is not

being used, this value is not required. Enter

the dimension of Lower Tool Vee Die Angle. See

Figure 7-2.

FIGURE 7-2 – Measuring the Vee Angle

Valid Range: 0° - 180°

Entry Format: XXX

Default Value: 0°

TOP OF MATERIAL: This value is entered once

per program. It represents the ram position

where the nose of the upper die just touches an

unbent piece of the material placed on the lower

die. If Angle Mode reversal is not being used, this

value is not required. Enter the ram position for

the location of the top of material. This can be

entered manually or by jogging the ram down

until it touches the material and using the TRN

key to copy the current ram position. (Use

SETUP mode to jog ram to correct location and

transfer value). See Figure 7-3.

7-3

Loading...

Loading...