Operation QUANTUM TIC

3-16 10/04

The black filling bar ceases

to apply from serial no. and

installation of EPROM

350 812-5.

Unloading in silo

operation

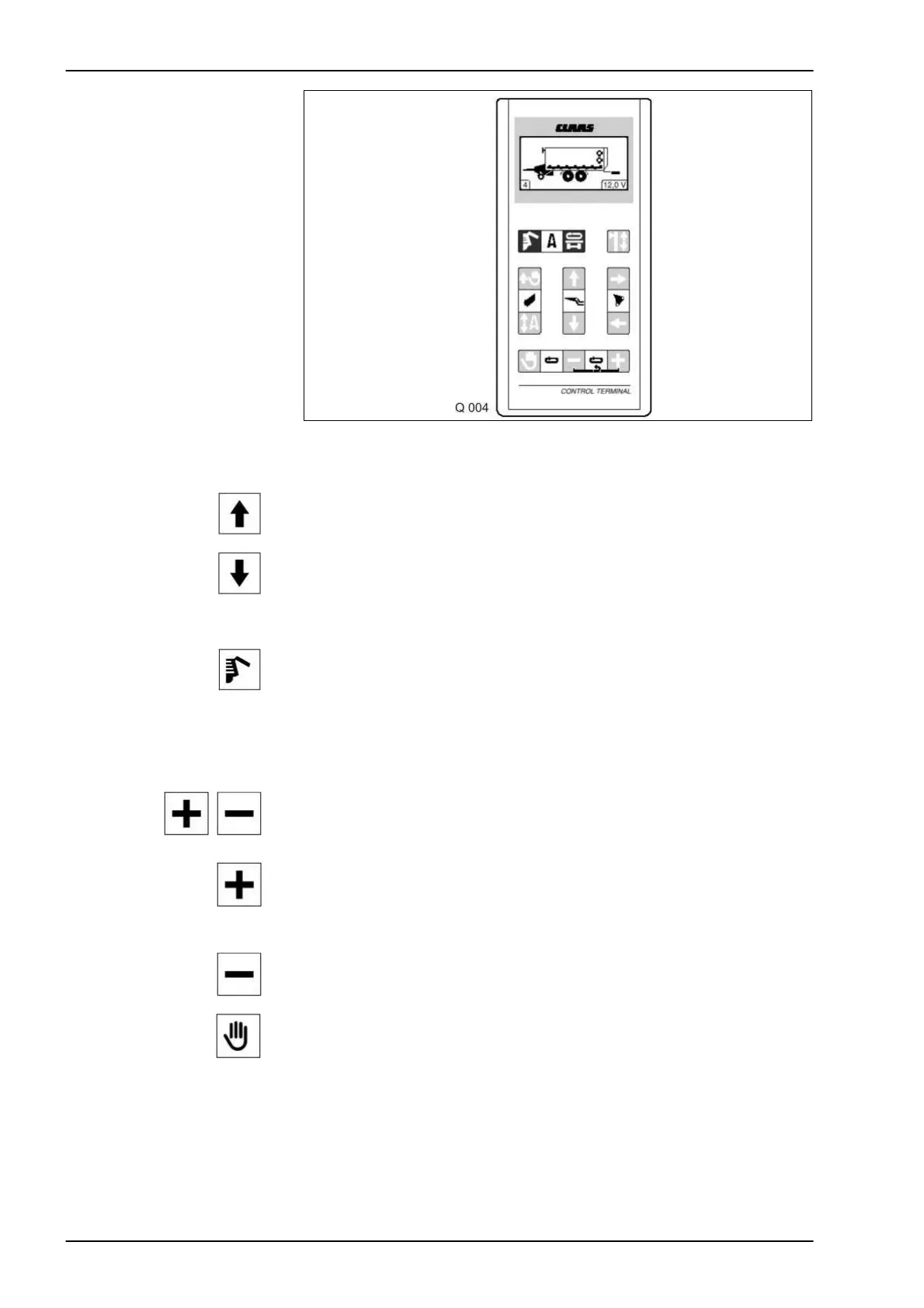

To switch on the control unit, set the hydraulic system to the pressure

setting. The display shows the forage wagon.

Press this button to raise the wagon over the articulated drawbar at the

front.

When unloading is complete, use this key to lower the wagon again. The

floor conveyor switches to the 4

th

stage.

Discharge of the load

space

Switch on the pto shaft. Press this button for unloading. The tailgate

opens, the shredder drums start running and the floor conveyor is

switched on after a short delay. To stop the unloading process, press this

button again.

Any blockage of the shredder drums (the cut-out clutch of the universal

drive shaft is activated) by the material requires reversing the floor

conveyor.

Press these buttons simultaneously to reversing the floor conveyor. After

the floor conveyor has been reversed, the floor conveyor speed must be

increased by pressing the + button.

Pressing this button increases the floor conveyor speed. By increasing

the speed numbers up to speed 9 and pressing this key once again, an

“S” appears in the control panel display = quick conveyor speed due to 2-

speed hydraulic motor.

Pressing this button decreases the floor conveyor speed.

When pressing this key during the whole unloading process, the adjusted

floor conveyor speed is saved for further unloading processes.

Loading...

Loading...