I STANDING PILOT

BURNER

The standing pilot model furnaces have

one pilot burner. The burner has a

thermocouple to sense pilot flame and

to prevent the gas valve from opening if

the pilot light goes out.

There is a pilot draft hood over the pilot

flame to allow it to vent its products of

combustion. This draft hood connects to

the induced draft blower housing above.

For this reason -

DO NOT INSTALL A

STANDING PILOT FURNACE

HORIZONTALL V.

CAUSES FOR PILOT OUTAGES:

1. Improper furnace vent pipe size.

2. Improper vent pipe termination.

3. Inlet gas pressure is too high.

A. 5" - 10.5" max for natural gas

B. 11" - 13" max for LP gas

4.

Venting the furnace horizontally.

5. Improper location of the pilot

orifice.

6.

Inadequate combustion air to the

furnace.

•

7. Operating the furnace with the

blower door open or having

unsealed return air ducting.

8.

Improper location of the pilot burner

hood (elevate the tip of the pilot

burner hood 1/16" to 1/8" above the

main burner flame runner).

9.

Downdrafts in the vent system.

If pilot hood downdrafts occur,

install a gas diffuser plate

(AE-58417-01) in the pilot hood.

10. Failing thermocouple (less than 18

DC mV under no load condition).

11. Overtightening the brass

compression fitting on the pilot gas

line causing a misalignment of the

pilot orifice.

12. Wrong pilot orifice.

13. Moisture in the pilot gas line.

14.

Pilot draft hood bent or out of

alignment.

15. Moisture condensing in the

vent pipe flowing down in the pilot

flame.

If nuisance pilot outages continue,

replace the pilot assembly with Pilot

Assembly 62-22864-82.

Furnaces with date codes after

4393 have this new pilot assembly

in place.

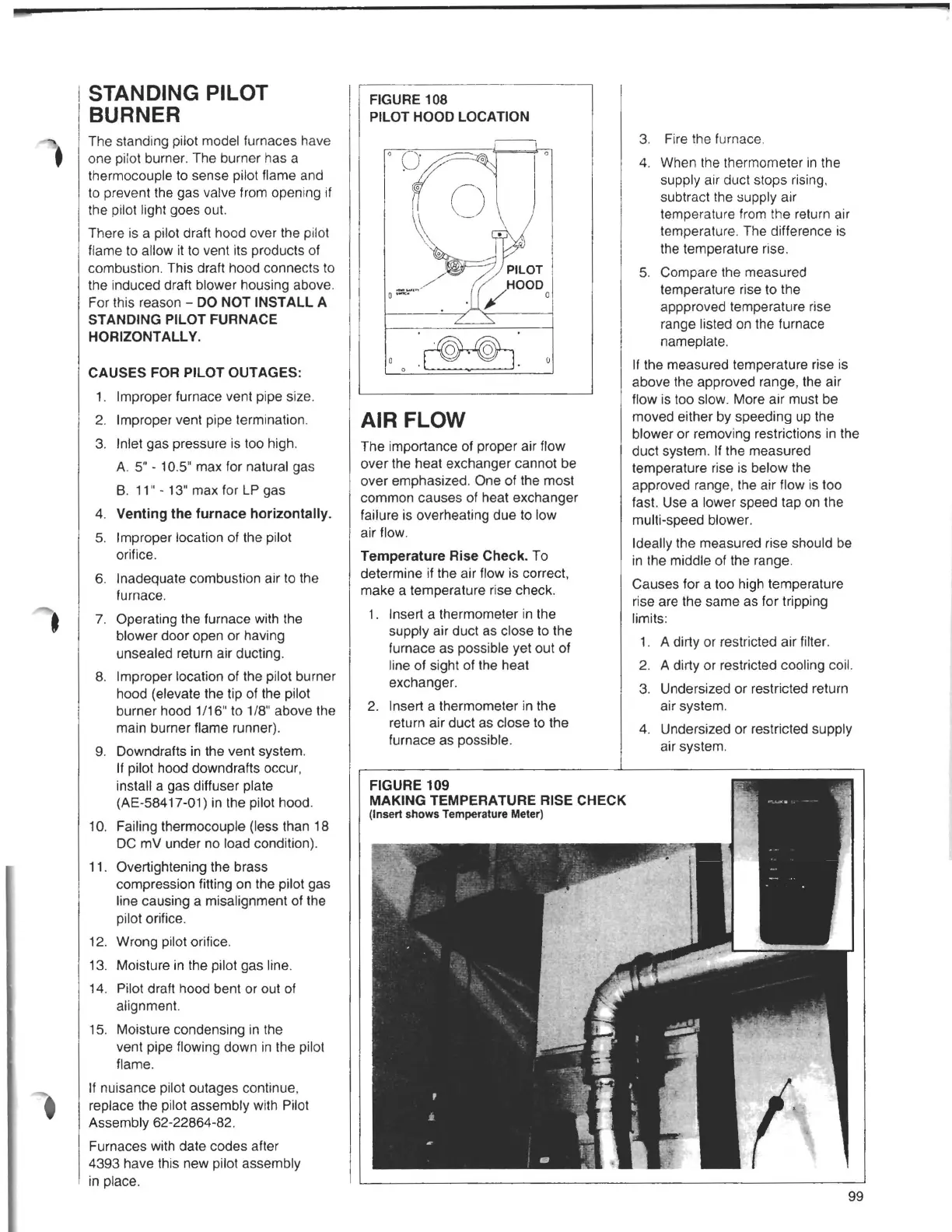

FIGURE 108

PILOT HOOD LOCATION

AIR FLOW

The importance of proper air flow

over the heat exchanger cannot be

over emphasized. One of the most

common causes of heat exchanger

failure is overheating due to low

air flow.

Temperature Rise Check. To

determine if the air flow is correct,

make a temperature rise check.

1. Insert a thermometer in the

supply air duct as close to the

furnace as possible yet out of

line of sight of the heat

exchanger.

2. Insert a thermometer in the

return air duct as close to the

furnace as possible.

3. Fire the furnace.

4. When the thermometer in the

supply air duct stops rising,

subtract the supply air

temperature from the return air

temperature. The difference is

the temperature rise.

5. Compare the measured

temperature rise to the

appproved temperature rise

range listed on the furnace

nameplate.

If the measured temperature rise is

above the approved range, the air

flow is too slow. More air must be

moved either by speeding up the

blower or removing restrictions in the

duct system. If the measured

temperature rise is below the

approved range, the air flow is too

fast. Use a lower speed tap on the

multi-speed blower.

Ideally the measured rise should be

in the middle of the range.

Causes for a too high temperature

rise are the same as for tripping

limits:

1. A dirty or restricted air filter.

2.

A dirty or restricted cooling coil.

3. Undersized or restricted return

air system.

4. Undersized or restricted supply

air system.

FIGURE 109

MAKING TEMPERATURE RISE CHECK

(Insert shows Temperature Meter)

99

Loading...

Loading...