HOT SURFACE

IGNITERS

The hot surface igniter is a silicon

carbide igniter with a ceramic base

and plug in connections. The igniter

did perform two functions. When

energized, the igniter temperature

reaches approximately 2600°F to light

the gas burners. Once the gas lights,

the igniter becomes a flame sensor

using the process of flame

rectification. Units with date codes

between 1893 and 3294 only use the

igniter to light the burners. A remote

flame sensor now detects flame. The

igniter has a 34-second warm up

period before the gas valve opens.

NOTE: Power polarity to the ignition

control board must be correct or the

flame sensing circuit cannot sense the

burner flame and the furnace shuts

down. Inadequate equipment and/or

chassis grounding can also result in

failure to sense flame

NOTE: Handle the igniter with care as

it is easily damaged.

Check. Unplug the igniter 2-prong

connector from the wiring harness to

the furnace control board prior to

conducting this test.

1. Call for heat at the thermostat.

2. Allow the induced draft blower to

operate for 30 seconds.

3. Use a voltmeter to measure the

voltage coming to the igniter at

the 2-prong connector junction

plug 30 seconds after the induced

draft blower starts.

4. If there is no voltage, and the

pressure switch is closed, replace

the control board.

5. If there is voltage, inspect the

igniter for:

A. cracks or damage to the

carbide tip

B. frayed or damaged wiring

C. properly seated pins in the

connector

6. Use an Ohmmeter to check the

resistance of the igniter. Make this

check with the igniter at room

temperature (70°-75°F).

A Norton 201 (black leads)

45-250 Ohms

8. ISi (Starlight) (orange leads)

20-300 Ohms

7. Be sure the igniter is positioned

properly in the flame.

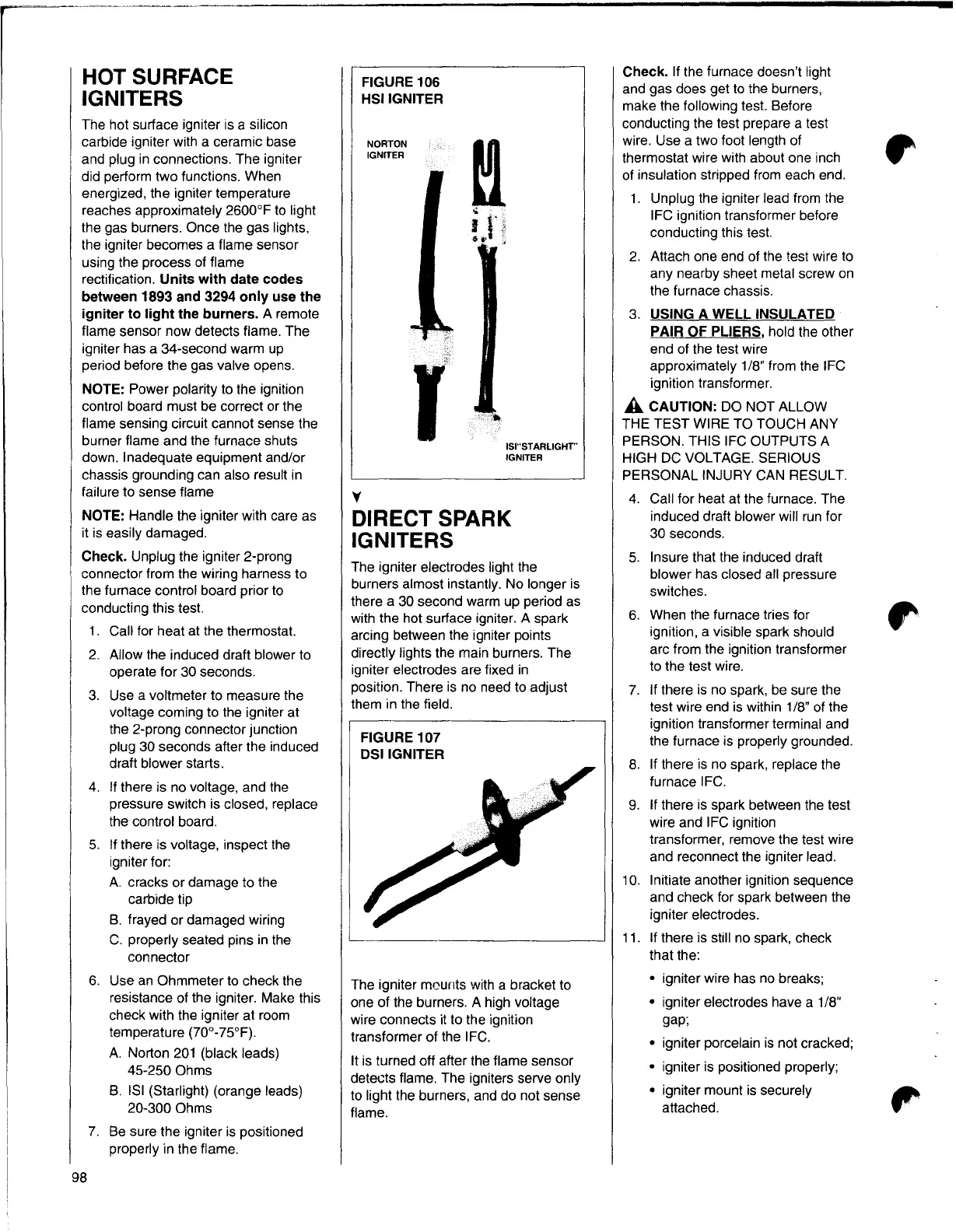

FIGURE 106

HSI IGNITER

NORTON

IGNITER

r

ISl"STARLIGHr'

IGNITER

y

DIRECT SPARK

IGNITERS

The igniter electrodes light the

burners almost instantly. No longer is

there a 30 second warm up period as

with the hot surface igniter. A spark

arcing between the igniter points

directly lights the main burners. The

igniter electrodes are fixed in

position. There is no need to adjust

them in the field.

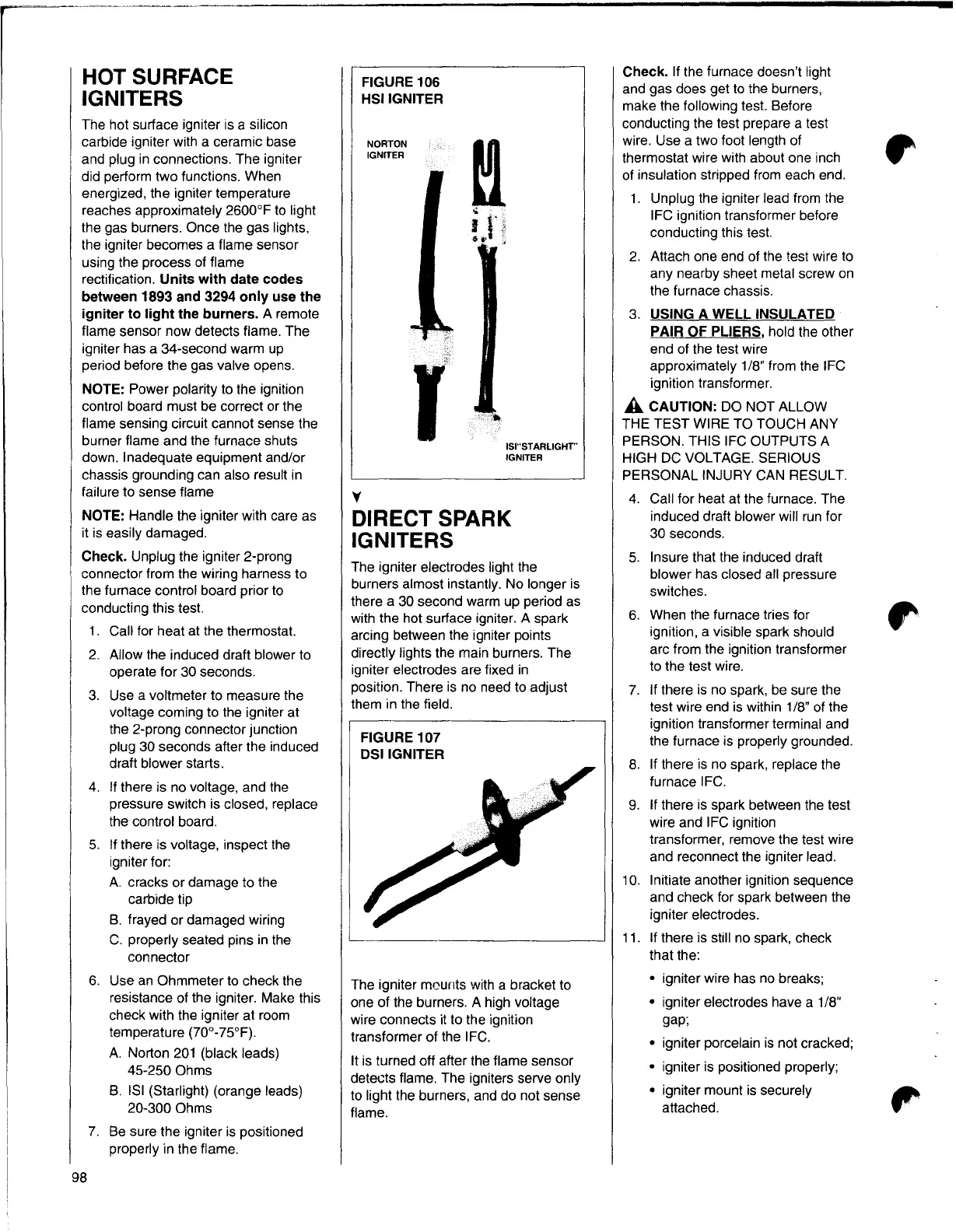

FIGURE 107

OSI IGNITER

The igniter mounts with a bracket to

one of the burners.

A high voltage

wire connects it to the ignition

transformer of the IFC.

It is turned off after the flame sensor

detects flame. The igniters serve only

to light the burners, and do not sense

flame.

Check. If the furnace doesn't light

and gas does get to the burners,

make the following test. Before

conducting the test prepare a test

wire. Use a two foot length of

thermostat wire with about one inch

of insulation stripped from each end.

1. Unplug the igniter lead from the

IFC ignition transformer before

conducting this test.

2. Attach one end of the test wire to

any nearby sheet metal screw on

the furnace chassis.

3. USING A WELL INSULATED

PAIR OF PLIERS, hold the other

end of the test wire

approximately 1/8" from the IFC

ignition transformer.

A CAUTION: DO NOT ALLOW

THE TEST WIRE TO TOUCH ANY

PERSON. THIS IFC OUTPUTS A

HIGH DC VOLTAGE. SERIOUS

PERSONAL INJURY CAN RESULT.

4. Call for heat at the furnace. The

induced draft blower will run for

30 seconds.

5. Insure that the induced draft

blower has closed all pressure

switches.

6. When the furnace tries for

ignition, a visible spark should

arc from the ignition transformer

to the test wire.

7. If there is no spark, be sure the

test wire end is within 1/8" of the

ignition transformer terminal and

the furnace is properly grounded.

8. If there is no spark, replace the

furnace IFC.

9. If there is spark between the test

wire and IFC ignition

transformer, remove the test wire

and reconnect the igniter lead.

10. Initiate another ignition sequence

and check for spark between the

igniter electrodes.

11. If there is still no spark, check

that the:

• igniter wire has no breaks;

• igniter electrodes have a 1/8"

gap;

• igniter porcelain is not cracked;

• igniter is positioned properly;

• igniter mount is securely

attached.

98

Loading...

Loading...