position of the screws marked SW1

and SW2. Use Figure 48 to set the

blower off timing.

The blower off timing on the UTEC

control depends on the position of

three small switches. Adjust the

blower off time delay by setting these

switches.

BLOWER WIRING CONNECTIONS

A CAUTION: DISCONNECT THE

ELECTRICAL SUPPLY TO THE

FURNACE BEFORE ATTEMPTING

TO CHANGE THE BLOWER

SPEED. FAILURE TO DISCONNECT

ELECTRICAL POWER MAY

RESULT IN PROPERTY DAMAGE

FROM FIRE OR PERSONAL

INJURY OR DEATH FROM

ELECTRICAL SHOCK.

The furnace control board, either

standing pilot or hot surface ignition,

comes wired with the heating speed

tap connected to the terminal marked

"HEAT" and cooling speed tap

connected to the terminal marked

"COOL." Any unused motor speed

taps connect to terminals marked

"M1" and "M2."

The motor speed taps may be

changed to fit the needs of a specific

installation. Reconnect any unused

motor leads to terminals "M1" and

"M2." Check the motor speed tap wire

color for the specific speed as

marked on the wiring diagram.

FIELD INSTALLED ACCESSORIES

1. Connect the line voltage wiring of

an electronic air cleaner to the

screw terminal "EAC" and neutral

on the Hot Surface Ignition

control boards.This powers the

EAC whenever the main blower

operates.

2. Connect the line voltage wiring of

a Humidifier to the screw

terminal "HUM" and neutral on

the Hot Surface Ignition control

boards. This powers a humidifier

whenever the burner is on and

the main blower operates in the

heating mode.

NOTE: The maximum amperage for

each option is 1.0 amps.

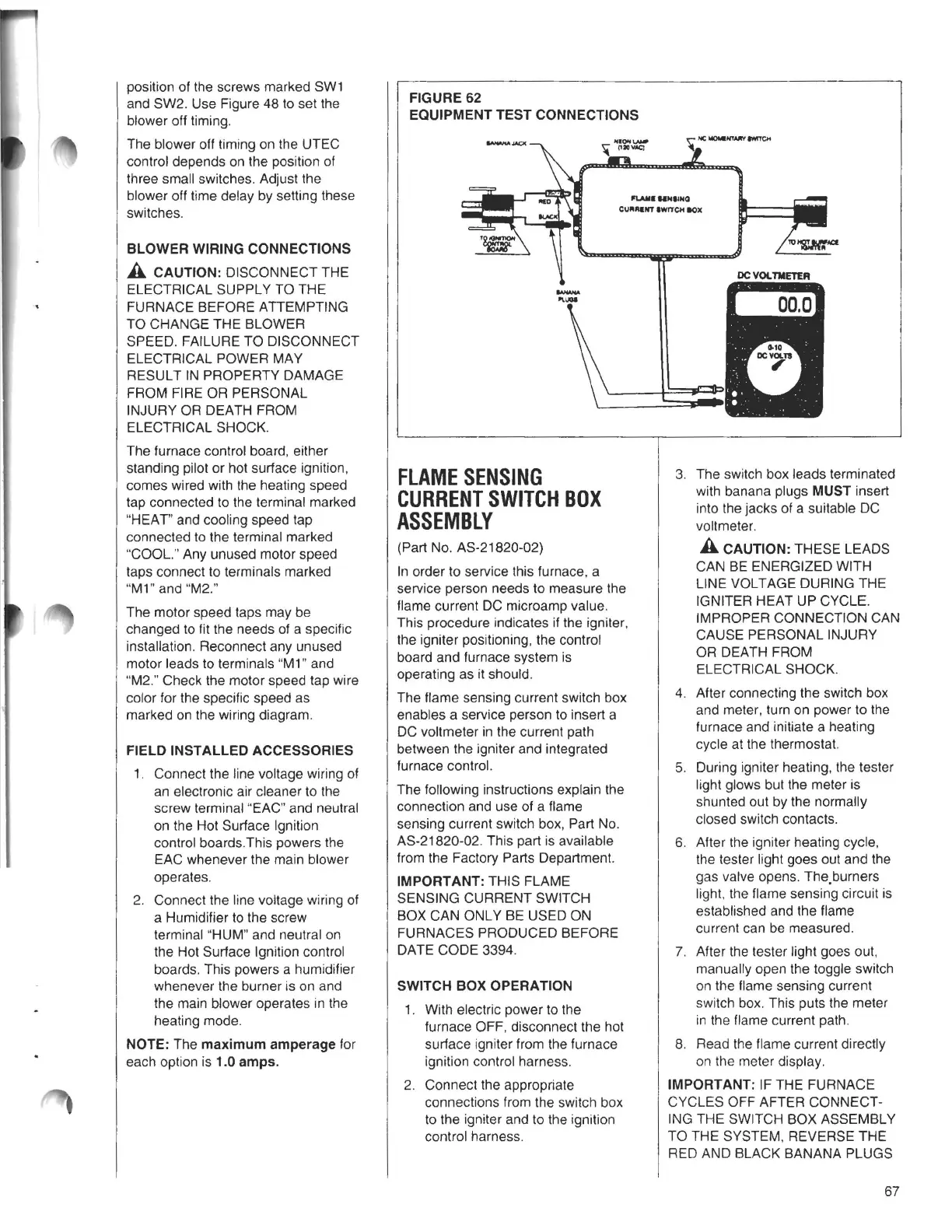

FIGURE62

EQUIPMENT TEST CONNECTIONS

l'I.AIIINHIIHQ

CURAaNT IWITC>< IIOX

-

.......

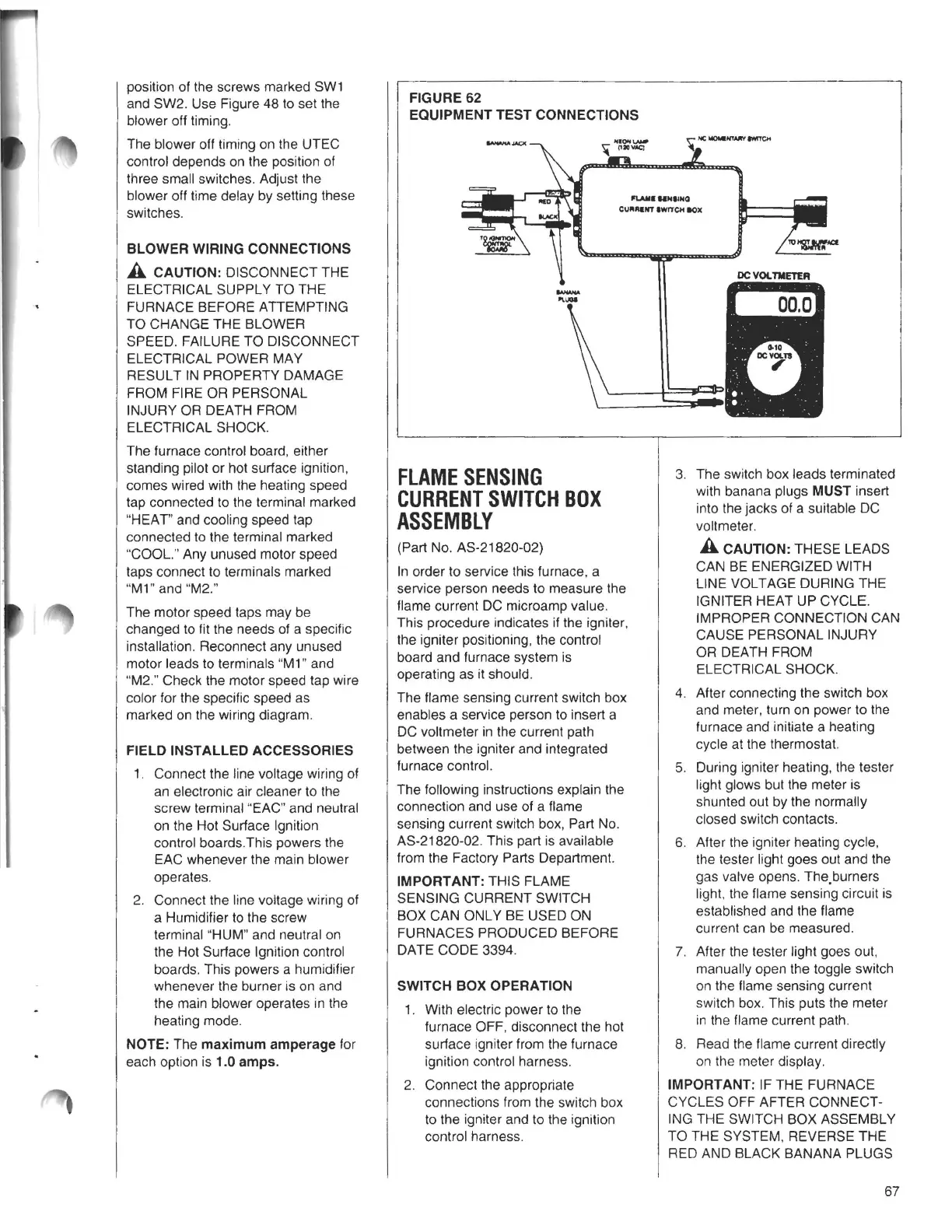

FLAMESENSING

CURRENTSWITCHBOX

ASSEMBLY

(Part No. AS-21820-02)

In order to service this furnace, a

service person needs to measure the

flame current DC microamp value.

This procedure indicates if the igniter,

the igniter positioning, the control

board and furnace system is

operating as it should.

The flame sensing current switch box

enables a service person to insert a

DC voltmeter in the current path

between the igniter and integrated

furnace control.

The following instructions explain the

connection and use of a flame

sensing current switch box, Part No.

AS-21820-02. This part is available

from the Factory Parts Department.

IMPORTANT: THIS FLAME

SENSING CURRENT SWITCH

BOX CAN ONLY BE USED ON

FURNACES PRODUCED BEFORE

DATE CODE 3394.

SWITCH BOX OPERATION

1. With electric power to the

furnace OFF, disconnect the hot

surface igniter from the furnace

ignition control harness.

2. Connect the appropriate

connections from the switch box

to the igniter and to the ignition

control harness.

'IU~

3. The switch box leads terminated

with banana plugs MUST insert

into the jacks of a suitable DC

voltmeter.

A CAUTION: THESE LEADS

CAN BE ENERGIZED WITH

LINE VOLTAGE DURING THE

IGNITER HEAT UP CYCLE.

IMPROPER CONNECTION CAN

CAUSE PERSONAL INJURY

OR DEATH FROM

ELECTRICAL SHOCK.

4. After connecting the switch box

and meter, turn on power to the

furnace and initiate a heating

cycle at the thermostat.

5. During igniter heating, the tester

light glows but the meter is

shunted out by the normally

closed switch contacts.

6. After the igniter heating cycle,

the tester light goes out and the

gas valve opens. The.burners

light, the flame sensing circuit is

established and the flame

current can be measured.

7. After the tester light goes out,

manually open the toggle switch

on the flame sensing current

switch box. This puts the meter

in the flame current path.

8. Read the flame current directly

on the meter display.

IMPORTANT: IF THE FURNACE

CYCLES OFF AFTER CONNECT-

ING THE SWITCH BOX ASSEMBLY

TO THE SYSTEM, REVERSE THE

RED AND BLACK BANANA PLUGS

67

Loading...

Loading...