TWINNING INSTRUCTIONS

Twinning or parallel operation of two

furnaces, installed side by side,

connected by a common duct system

and controlled by a single thermostat

can be done with

UTEC1012-925

integrated furnace controls using this

wiring kit. The addition of the two

blower compartment door interlock

switches in this kit assures that all

electrical power to both furnaces is

deenergized if either furnace blower

compartment door is not in place.

The additional switch, located in the

remote furnace is in series to the

furnace electrical supply as shown in

the wiring diagram, Figure 124, page

114. A line voltage connecting wire

between the electronic air cleaner

(EAC) terminals on both furnace

control boards assures simultaneous

indoor blower operation. The

switches, line voltage wiring and

mounting materials are included in

this kit. The thermostat and low

voltage (24 VAC) control wiring

materials are normal field supplied

items.

All electrical work must conform with

the requirements of local codes and

ordinances and the National Electric

Code ANSI/ NFPA- No. 70 latest

edition or the Canadian Electrical

Code Part 1 - CSA Standard C22.1

for Canadian installations.

ELECTRICAL WIRING

A WARNING:TURN OFF

ELECTRIC POWER AT THE FUSE

BOX OR SERVICE PANEL BEFORE

MAKING ANY ELECTRICAL CON-

NECTIONS. FAILURE TO DO SO

COULD RESULT IN AN ELECTRI-

CAL SHOCK HAZARD, PROPERTY

DAMAGE AND/OR PERSONAL

INJURY.

A WARNING: BOTH FURNACE

CABINETS MUST BE PERMA-

NENTLY GROUNDED. A GROUND

SCREW IN THE JUNCTION BOX IS

FOR THIS PURPOSE. GROUND

CONNECTIONS MUST BE

COMPLETED BEFORE MAKING

LINE VOLTAGE CONNECTIONS.

FAILURE TO DO SO COULD

RESULT IN AN ELECTRICAL

SHOCK HAZARD, PROPERTY

DAMAGE AND/OR PERSONAL

INJURY.

THE FURNACES MUST BE

INSTALLED SO THE ELECTRICAL

COMPONENTS ARE PROTECTED

FROM WATER.

A WARNING: ELECTRICAL

POWER MUST BE SUPPLIED TO

BOTH FURNACES FROM THE

SAME SEPARATE BRANCH

CIRCUIT. FAILURE TO DO SO

COULD RESULT IN EXPOSING

THE FURNACE CONTROLS TO

AN OVER VOLT AGE (230 VAC)

CONDITION. THIS COULD RESULT

IN DESTRUCTION OF THE

CONTROLBOARDS,PROPERTY

DAMAGE AND/OR PERSONAL

INJURY.

A WARNING: L 1 (HOT) AND

NEUTRAL POLARITY MUST BE

OBSERVED WHEN MAKING FIELD

CONNECTIONS TO THE FUR-

NACES. FAILURE TO DO SO

COULD RESULT IN A DIRECT

SHORT VIA THE CONNECTION

BETWEEN THE "EAC" TERMINALS

WHEN THE INDOOR BLOWER

RELAY CLOSES. THIS COULD

RESULT IN DESTRUCTION OF THE

CONTROLBOARDS,PROPERTY

DAMAGE AND/OR PERSONAL

INJURY.

The furnaces must be on the same

branch circuit with adequate ampacity

and overcurrent protections. Do not

use existing lighting or other circuits.

NOTE: See the furnace rating plates

for motor H.P. ratings, electrical

characteristics, and amp draw.

NOTE: Use time delay fuses or circuit

breakers.

NOTE: Use the wiring diagram,

Figure 124, page 114 when installing

this twinning kit.

INSTALLATION PRO

CEDURES

Install the furnaces si de by side and

connect to the comm on supply and

return duct system. F ollow the

r

furnace installation in

structions. It

may be convenient to

convert the

right hand furnace to right side gas

and electrical supply.

1. Install the two bo xes from the kit

in the furnace jac kets using the

screws provided before locating

the furnaces. Re move the

knockouts as req uired. Insert the

snap bushings a nd plug buttons

while access is a vailable.

2. Identify the furna ces as number

1 and 2 for wiring

purposes. The

wiring diagram ar

bitrarily shows

furnace 1 on the I

eft.

3.

Turn off the elect

rical supply to

both furnaces bet ore making any

electrical connect

ions.

4. Disconnect and r emove the

control transform

er from furnace

2. Remove the bl ack and white

line voltage trans former leads

from the "L 1" and "neutral"

terminals on cont

rol board 2.

Remove only the

red and yellow

transformer lead wires from the

r

"24 VAC" and "C OM" terminals.

5. Remove the blac k wires

connecting the bl

ower door

switch (PBS) and "L 1" on the

control boards in furnaces 1

and 2.

6. Install the switch

es from the kit in

the boxes. Insert each switch in

the rectangular mounting hole.

7. Install the line vol tage

interconnecting wires as shown

in the wiring diag ram. Route the

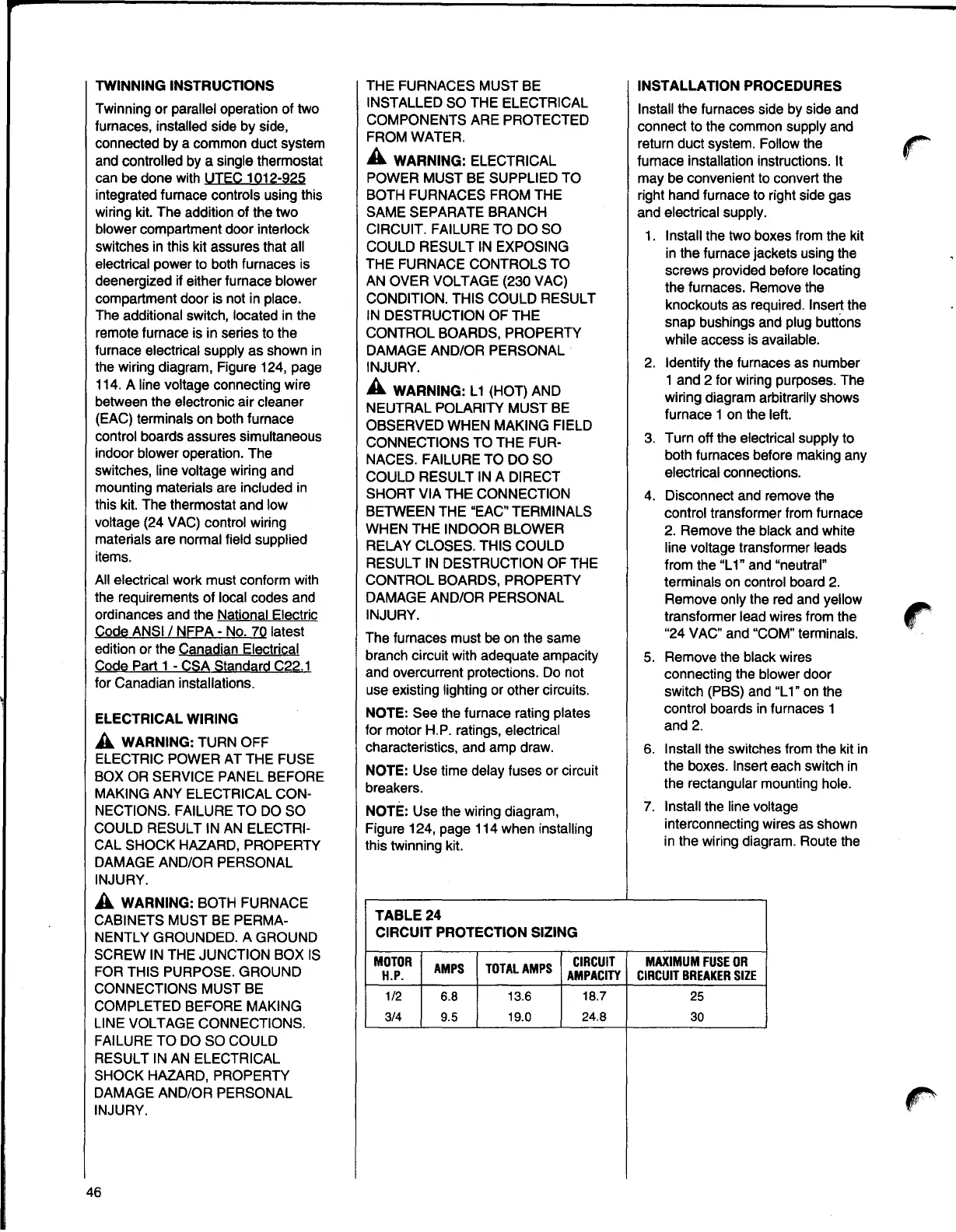

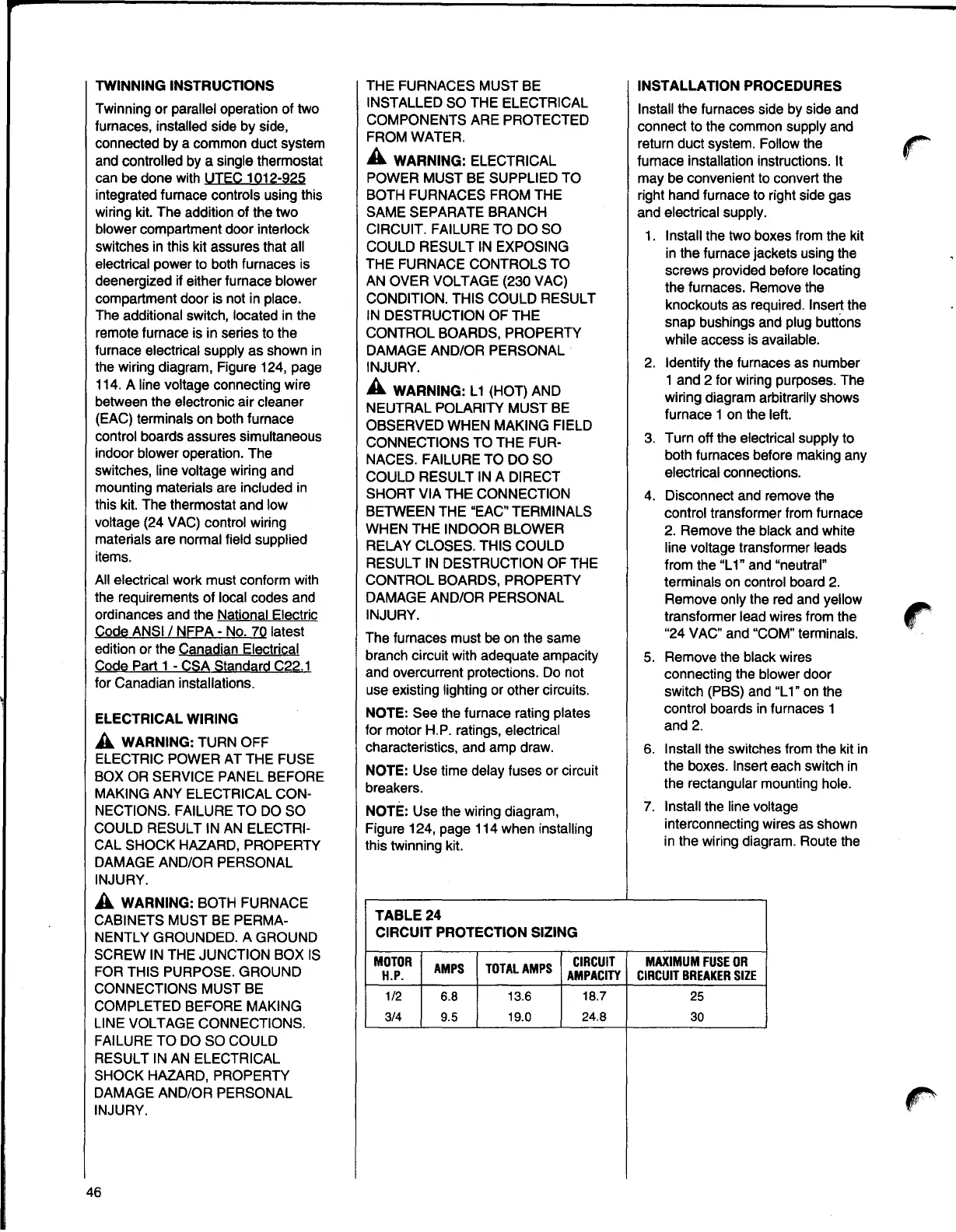

TABLE24

CIRCUIT PROTECTION SIZING

MOTOR

AMPS TOTALAMPS

CIRCUIT

H.P. AMPACITY

1/2 6.8 13.6 18.7

3/4 9.5 19.0

24.8

MAXIMUMFUSEOR

CIRCUITBREAKERSIZE

25

30

46

Loading...

Loading...