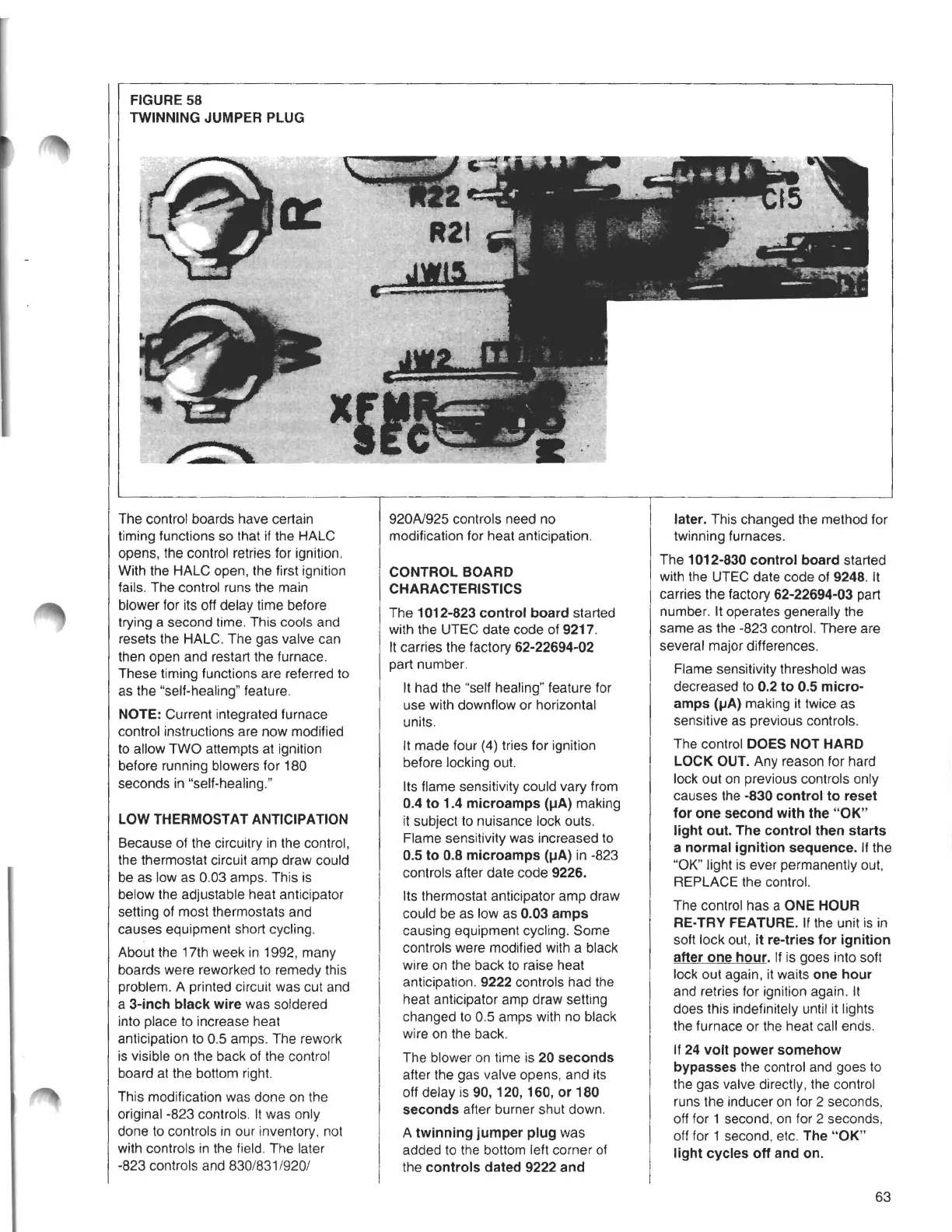

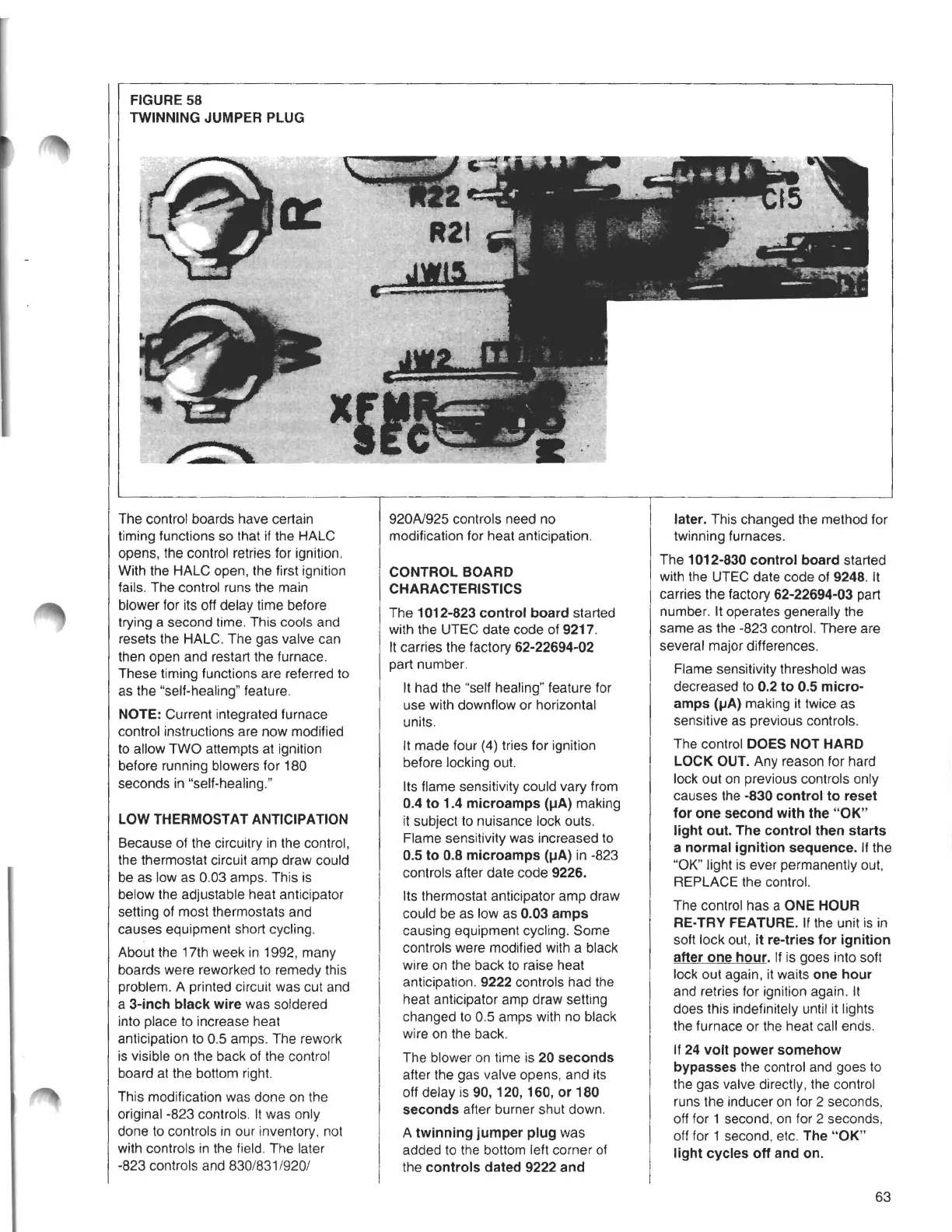

FIGURE 58

TWINNING JUMPER PLUG

The control boards have certain

timing functions so that if the HALC

opens, the control retries for ignition.

With the HALC open, the first ignition

fails. The control runs the main

blower for its off delay time before

trying a second time. This cools and

resets the HALC. The gas valve can

then open and restart the furnace.

These timing functions are referred to

as the "self-healing" feature.

NOTE: Current integrated furnace

control instructions are now modified

to allow TWO attempts at ignition

before running blowers for 180

seconds in "self-healing."

LOW THERMOSTAT ANTICIPATION

Because of the circuitry in the control,

the thermostat circuit amp draw could

be as low as 0.03 amps. This is

below the adjustable heat anticipator

setting of most thermostats and

causes equipment short cycling.

About the 17th week in 1992, many

boards were reworked to remedy this

problem. A printed circuit was cut and

a 3-inch black wire was soldered

into place to increase heat

anticipation to 0.5 amps. The rework

is visible on the back of the control

board at the bottom right.

This modification was done on the

original -823 controls. It was only

done to controls in our inventory, not

with controls in the field. The later

-823 controls and 830/831/920/

920A/925 controls need no

modification for heat anticipation.

CONTROL BOARD

CHARACTERISTICS

The 1012-823 control board started

with the UTEC date code of 9217.

It carries the factory 62-22694-02

part number.

It had the "self healing" feature for

use with downflow or horizontal

units.

II made four (4) tries for ignition

before locking out.

Its flame sensitivity could vary from

0.4 to 1.4 microamps (µA) making

it subject to nuisance lock outs.

Flame sensitivity was increased to

0.5 to 0.8 microamps (µA) in -823

controls after date code 9226.

Its thermostat anticipator amp draw

could be as low as 0.03 amps

causing equipment cycling. Some

controls were modified with a black

wire on the back to raise heat

anticipation. 9222 controls had the

heat anticipator amp draw setting

changed to 0.5 amps with no black

wire on the back.

The blower on time is 20 seconds

after the gas valve opens, and its

off delay is 90, 120, 160, or 180

seconds after burner shut down.

A twinning jumper plug was

added to the bottom left corner of

the controls dated 9222 and

later. This changed the method for

twinning furnaces.

The 1012-830 control board started

with the UTEC date code of 9248. It

carries the factory 62-22694-03 part

number. It operates generally the

same as the -823 control. There are

several major differences.

Flame sensitivity threshold was

decreased to 0.2 to 0.5 micro-

amps (µA) making it twice as

sensitive as previous controls.

The control DOES NOT HARD

LOCK OUT. Any reason for hard

lock out on previous controls only

causes the -830 control to reset

for one second with the "OK"

light out. The control then starts

a normal ignition sequence. If the

"OK" light is ever permanently out,

REPLACE the control.

The control has a ONE HOUR

RE-TRY FEATURE. If the unit is in

soft lock out, it re-tries for ignition

after one hour. If is goes into soft

lock out again, it waits one hour

and retries for ignition again. It

does this indefinitely until it lights

the furnace or the heat call ends.

If 24 volt power somehow

bypasses the control and goes to

the gas valve directly, the control

runs the inducer on for 2 seconds

off for 1 second, on for 2 seconds'

off for 1 second, etc. The "OK" '

light cycles off and on.

63

Loading...

Loading...