ABOVE FLOOR

REC'D. BY SOME

MANUAL GAS VALVE

~UNION

BURNERS

GAS SUPPLY AND PIPING

IMPORTANT: ANY ADDITIONS,

CHANGES OR CONVERSIONS

REQUIRED FOR THE FURNACE TO

SATISFACTORILY MEET THE

APPLICATION NEEDS SHOULD BE

MADE BY A QUALIFIED FACTORY

DISTRIBUTOR OR LOCAL

SERVICE CONTRACTOR USING

SPECIFIED OR APPROVED

PARTS.

IMPORTANT: CONNECT THIS

FURNACE ONLY TO GAS

SUPPLIED BY A COMMERCIAL

UTILITY.

IMPORTANT: A U.L. RECOGNIZED

FUEL GAS AND CO DETECTOR(S)

ARE RECOMMENDED IN ALL

APPLICATIONS, AND THEIR

INSTALLATION SHOULD BE IN

ACCORDANCE WITH THE

DETECTOR MANUFACTURER'S

RECOMMENDATIONS AND/OR

LOCAL LAWS, RULES,

REGULATIONS OR CUSTOMS.

A WARNING: THIS FURNACE IS

EQUIPPED AT THE FACTORY

FOR USE ON NATURAL GAS.

CONVERSION TO LP (LIQUIFIED

PETROLEUM) GAS REQUIRES A

SPECIAL KIT SUPPLIED BY THE

DISTRIBUTOR OR MANUFAC-

TURER. CONSULT THE FURNACE

RATING PLATE, PARTS LIST OR

WARRANTY FOR MAILING

ADDRESSES. FAILURE TO USE

THE PROPER CONVERSION KIT

CAN CAUSE FIRE, CARBON

MONOXIDE POISONING,

EXPLOSION, PERSONAL INJURY,

PROPERTY DAMAGE OR DEATH.

IMPORTANT: ENSURE THAT THE

FURNACE GAS CONTROL VALVE

NOT BE SUBJECTED TO HIGH

GAS LINE SUPPLY PRESSURES.

DISCONNECT THE FURNACE AND

ITS INDIVIDUAL SHUT-OFF VALVE

FROM THE GAS SUPPLY PIPING

DURING

ANY PRESSURE

TESTING THAT EXCEEDS

1/2 P.S.I.G. (3.48 KPA).

IMPORTANT:

WHEN MAKING GAS

PIPE CONNECTIONS, USE A BACK

UP WRENCH TO PREVENT ANY

TWISTING OF THE CONTROL

ASSEMBLY AND GAS VAL VE. ANY

STRAINS ON THE GAS VALVE CAN

CHANGE THE POSITION OF THE

GAS ORIFICES IN THE BURNERS.

THIS CAN CAUSE ERRATIC

FURNACE OPERATION.

To check for leaks in the gas piping,

use an approved chloride-free soap

and water solution, an electronic

combustible gas detector (see Figure

31 ), or other approved method.

A_ WARNING: DO NOT USE AN

OPEN FLAME TO CHECK FOR GAS

LEAKS. THIS CAN CAUSE FIRE, OR

AN EXPLOSION RESULTING IN

PERSONALINJURY,PROPERTY

DAMAGE OR DEATH.

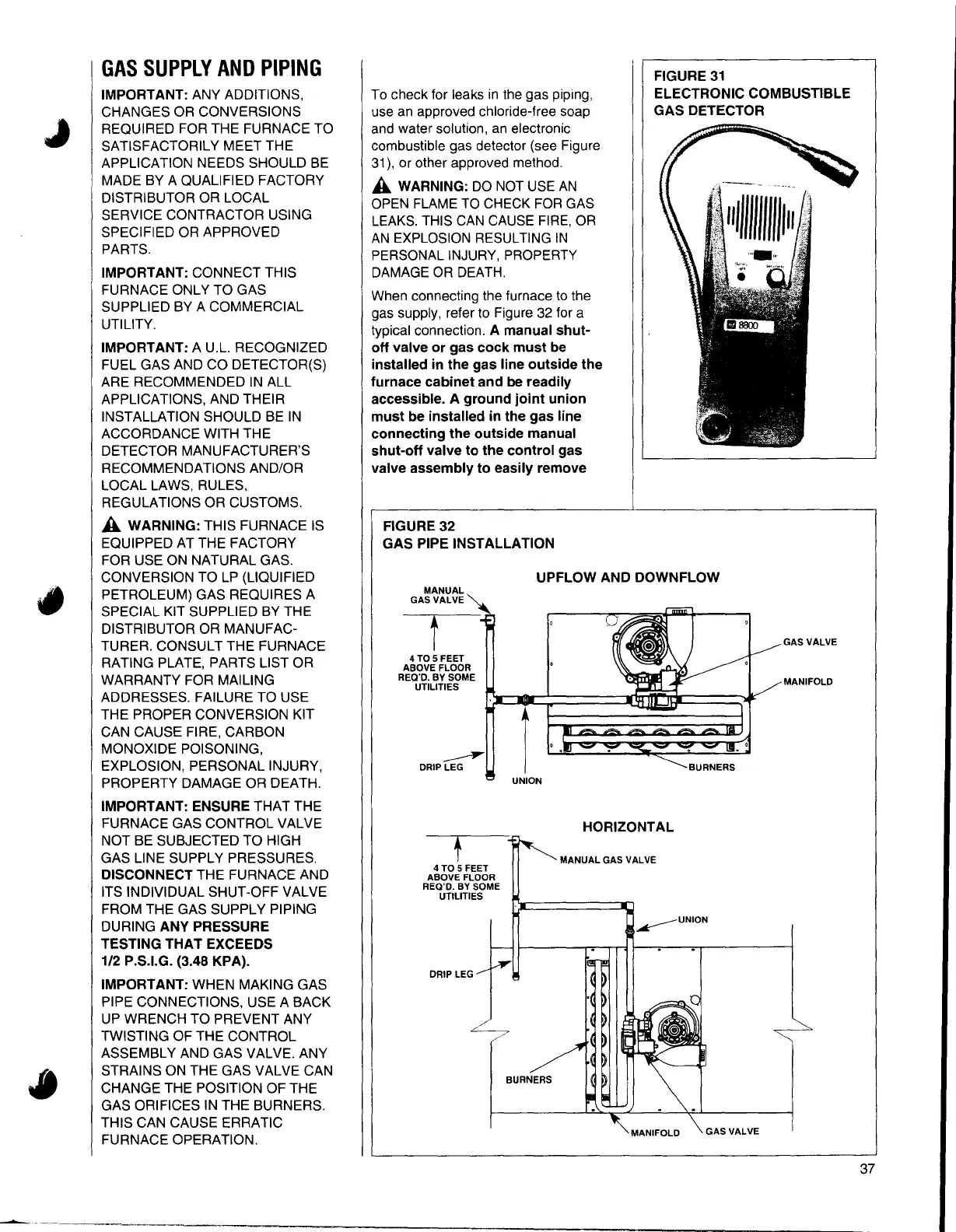

When connecting the furnace to the

gas supply, refer to Figure 32 for a

typical connection.

A manual shut-

off valve or gas cock must be

installed in the gas line outside the

furnace cabinet and be readily

accessible. A ground joint union

must be installed in the gas line

connecting the outside manual

shut-off valve to the control gas

valve assembly to easily remove

FIGURE32

GAS PIPE INSTALLATION

UPFLOW AND DOWNFLOW

MANUAL

GAS VALVE~

t

GAS VALVE

4 TO 5 FEET

ABOVE FLOOR

REC'D. BY SOME

MANIFOLD

UTILITIES

I

UNION

HORIZONTAL

t

4 TO 5 FEET

UTILITIES

DRIP LEG

FIGURE 31

ELECTRONIC COMBUSTIBLE

GAS DETECTOR

37

Loading...

Loading...