Ii

control has internal problems and

needs replacement. (The OK LED

flashes if two furnaces are not

twinned properly.)

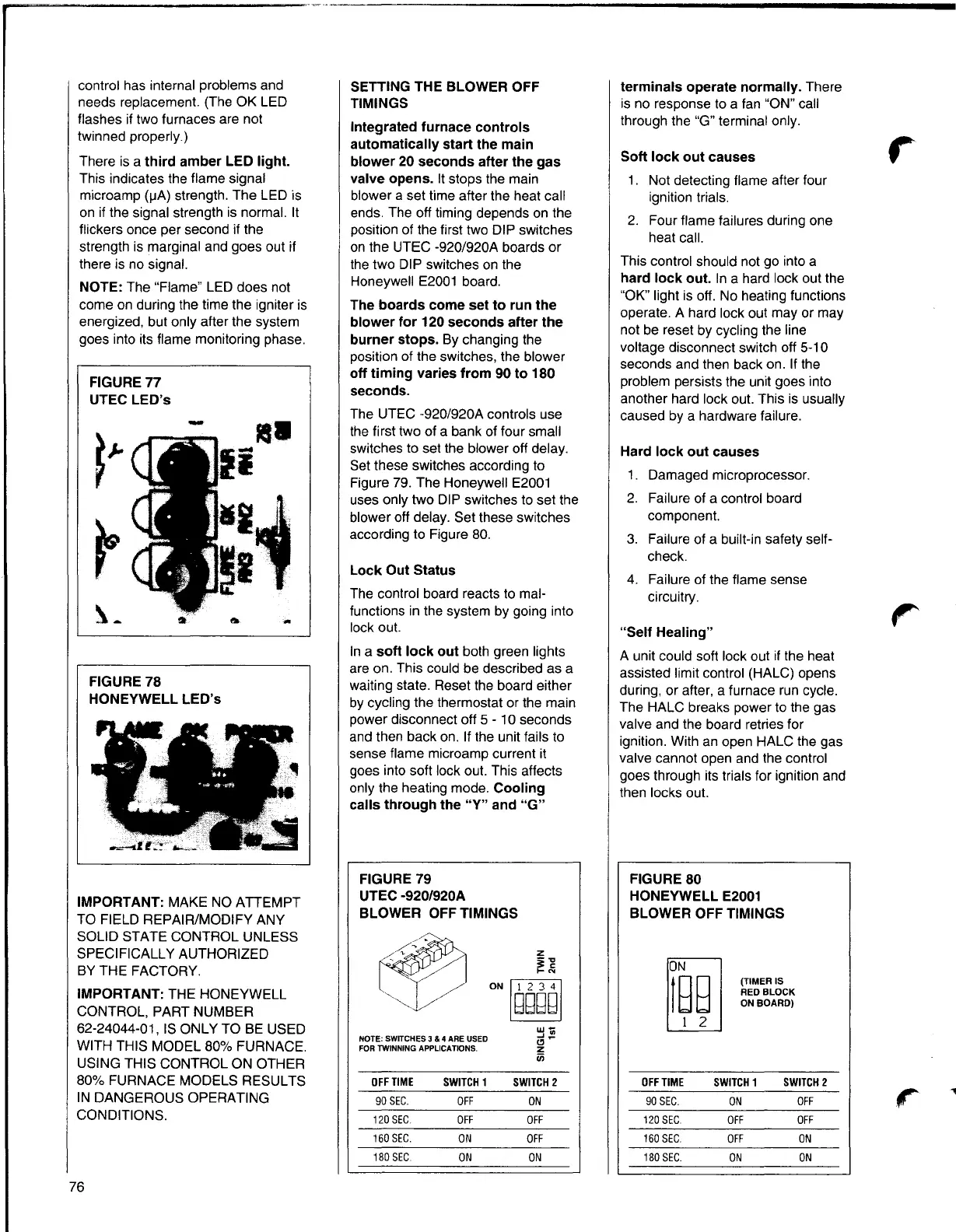

There is a third amber LED light.

This indicates the flame signal

microamp

(µA)strength. The LED is

on if the signal strength is normal. It

flickers once per second if the

strength is marginal and goes out if

there is no signal.

NOTE: The "Flame" LED does not

come on during the time the igniter is

energized, but only after the system

goes into its flame monitoring phase.

FIGURE 77

UTEC LED's

-

rs

■

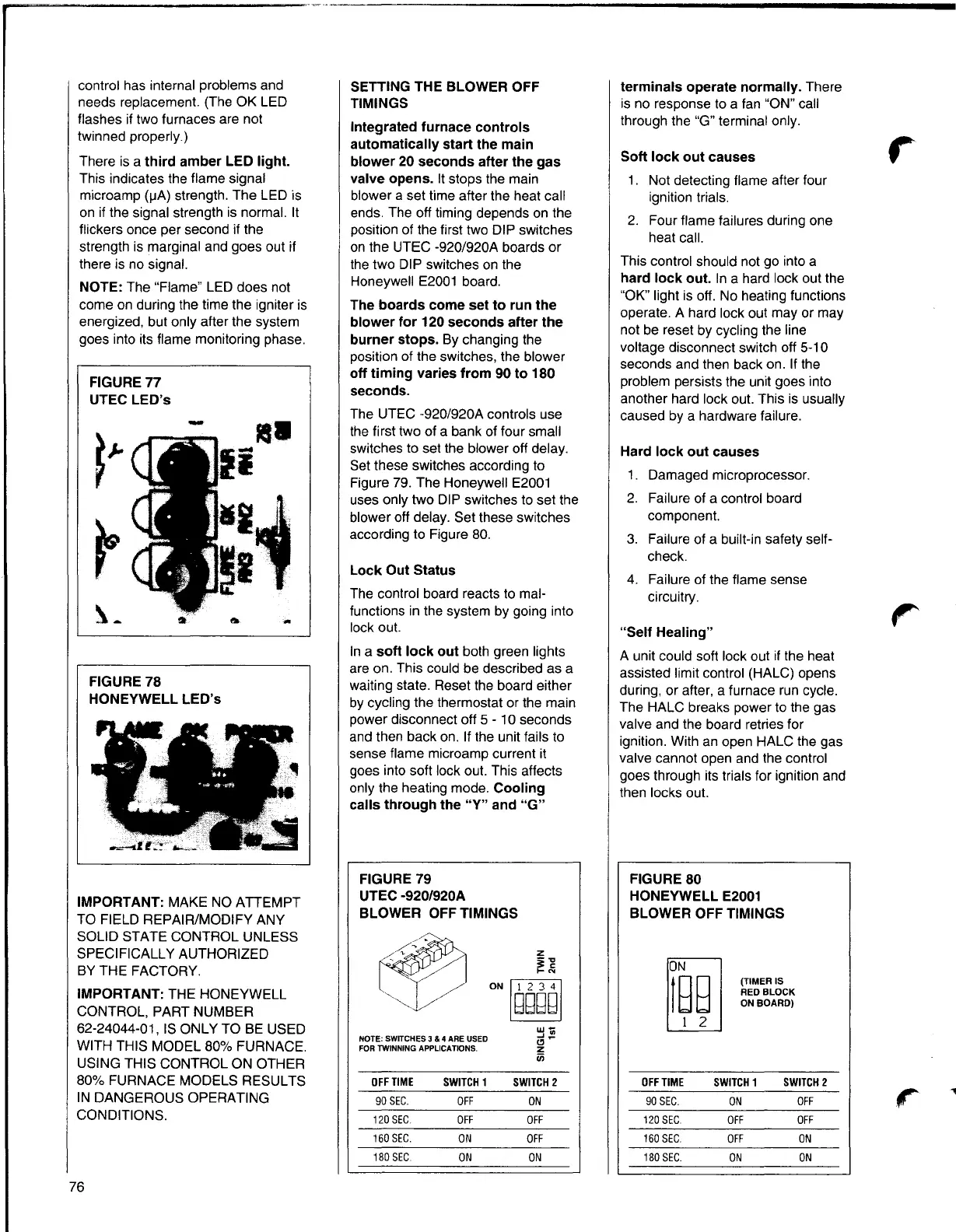

blower off delay. Set these switches

according to Figure 80.

Lock Out Status

,:1

-

FIGURE 78

HONEYWELL LED's

IMPORTANT: MAKE NO ATTEMPT

TO FIELD REPAIR/MODIFY ANY

SOLID STATE CONTROL UNLESS

SPECIFICALLY AUTHORIZED

BY THE FACTORY.

IMPORTANT: THE HONEYWELL

CONTROL, PART NUMBER

62-24044-01, IS ONLY TO BE USED

WITH THIS MODEL 80% FURNACE.

USING THIS CONTROL ON OTHER

80% FURNACE MODELS RESULTS

IN DANGEROUS OPERATING

CONDITIONS.

SETTING THE BLOWER OFF

TIMINGS

Integrated furnace controls

automatically start the main

blower 20 seconds after the gas

valve opens. It stops the main

blower a set time after the heat call

ends. The off timing depends on the

position of the first two DIP switches

on the UTEC -920/920A boards or

the two DIP switches on the

Honeywell E2001 board.

The boards come set to run the

blower for 120 seconds after the

burner stops. By changing the

position of the switches, the blower

off timing varies from 90 to 180

seconds.

The UTEC -920/920A controls use

the first two of a bank of four small

switches to set the blower off delay.

Set these switches according to

Figure 79. The Honeywell E2001

uses only two DIP switches to set the

The control board reacts to mal-

functions in the system by going into

lock out.

In a soft lock out both green lights

are on. This could be described as a

waiting state. Reset the board either

by cycling the thermostat or the main

power disconnect off 5 - 1

O seconds

and then back on. If the unit fails to

sense flame microamp current it

goes into soft lock out. This affects

only the heating mode. Cooling

calls through the "Y" and "G"

FIGURE 79

UTEC -920/920A

BLOWER OFF TIMINGS

z

i -g

.....

~

lgggglON

w-

.J .,

NOTE: SWITCHES 3 & 4 ARE USED

Cl -

FOR TWINNING APPLICATIONS.

z

iii

OFF TIME

90 SEC.

120 SEC.

160 SEC.

180 SEC.

SWITCH1

OFF

OFF

ON

ON

SWITCH2

ON

OFF

OFF

ON

terminals operate normally. There

is no response to a fan "ON"call

through the "G" terminal only.

Soft lock out causes

r

1. Not detecting flame after four

ignition trials.

2. Four flame failures during one

heat call.

This control should not go into a

hard lock out. In a hard lock out the

"OK" light is off. No heating functions

operate. A hard lock out may or may

not be reset by cycling the line

voltage disconnect switch off 5-10

seconds and then back on. If the

problem persists the unit goes into

another hard lock out. This is usually

caused by a hardware failure.

Hard lock out causes

1. Damaged microprocessor.

2. Failure of a control board

component.

3. Failure of a built-in safety self-

check.

4. Failure of the flame sense

circuitry.

"Self Healing"

A unit could soft lock out if the heat

assisted limit control (HALC) opens

during, or after, a furnace run cycle.

The HALC breaks power to the gas

valve and the board retries for

ignition. With an open HALC the gas

valve cannot open and the control

goes through its trials for ignition and

then locks out.

FIGURE80

HONEYWELL E2001

BLOWER OFF TIMINGS

(TIMER IS

RED BLOCK

ON BOARD)

OFF TIME SWITCH1 SWITCH2

90 SEC. ON OFF

r

120 SEC.

OFF OFF

160 SEC.

OFF ON

180 SEC.

ON

ON

76

Loading...

Loading...