••

REMOTEFLAME

SENSINGROD

IMPORTANT: FURNACES PRO-

DUCED AFTER DATE CODE 3394

HAVE THE REMOTE FLAME

SENSOR CONNECTED DIRECTLY

TO THE INTEGRATED FURNACE

CONTROL BOARD.

The remote flame sensor monitors

the system for burner ignition and

operation. It mounts in front of the

last burner on the end of the burner

support opposite the hot surface

igniter. It connects to pin 7 of the

9-pin plug on the integrated furnace

control board.

The sensor monitors flame using the

process of flame rectification. The

sensor is energized from the 115 volt

circuit during burner operation. The

flame conducts a small electrical

current to the chassis ground of the

burners. This current is in the

microamp

(µA)range.

The flame sensing current is

dependent on the control board, the

contact area of the flame on the

sensing rod, the burner surface, and

the chassis (cabinet) ground path

between burner and control board.

Typical flame sense current is 2.0 -

4.0 DC µA, but can be as high as 7.0

µA. The I FC should hold the gas

valve on line with flame sensing

currents as low as 0.5 DC µA.

Check. Use a microamp meter or the

microamp setting on a digital volt-

Ohmmeter to measure the flame

current signal.

1. Turn off the main electrical

power to the furnace.

2. Disconnect the lead from the

flame sensor.

3. Connect one lead of a microamp

meter to the flame sensor.

4. Connect the second lead of the

microamp meter to the wire just

removed from the sensor.

5. Set the microamp meter to the

1 - 10 DC microamp scale.

6. Turn power back on to the

furnace and call for heat at the

thermostat.

7. After the burners light note the

microamp reading on the meter.

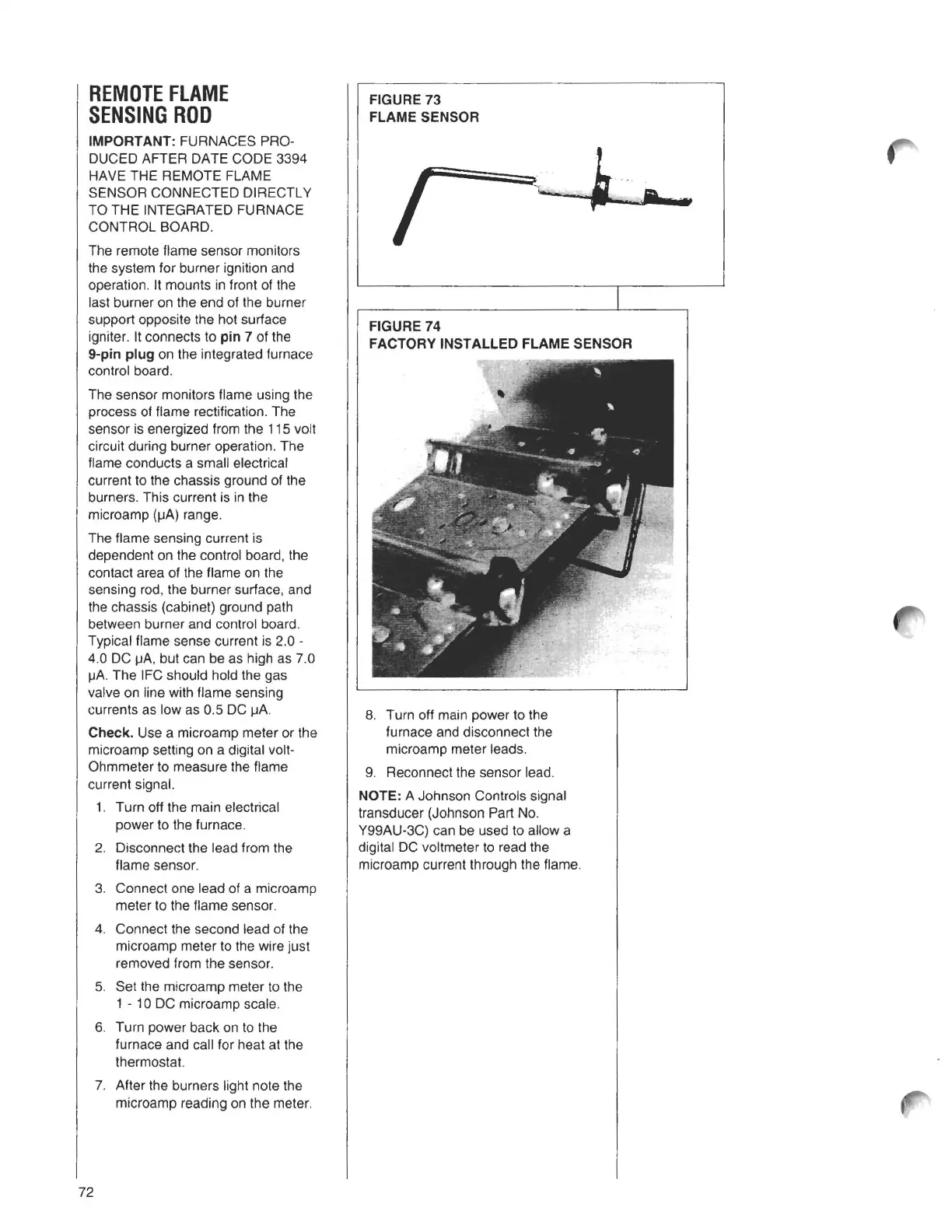

FIGURE 73

FLAME SENSOR

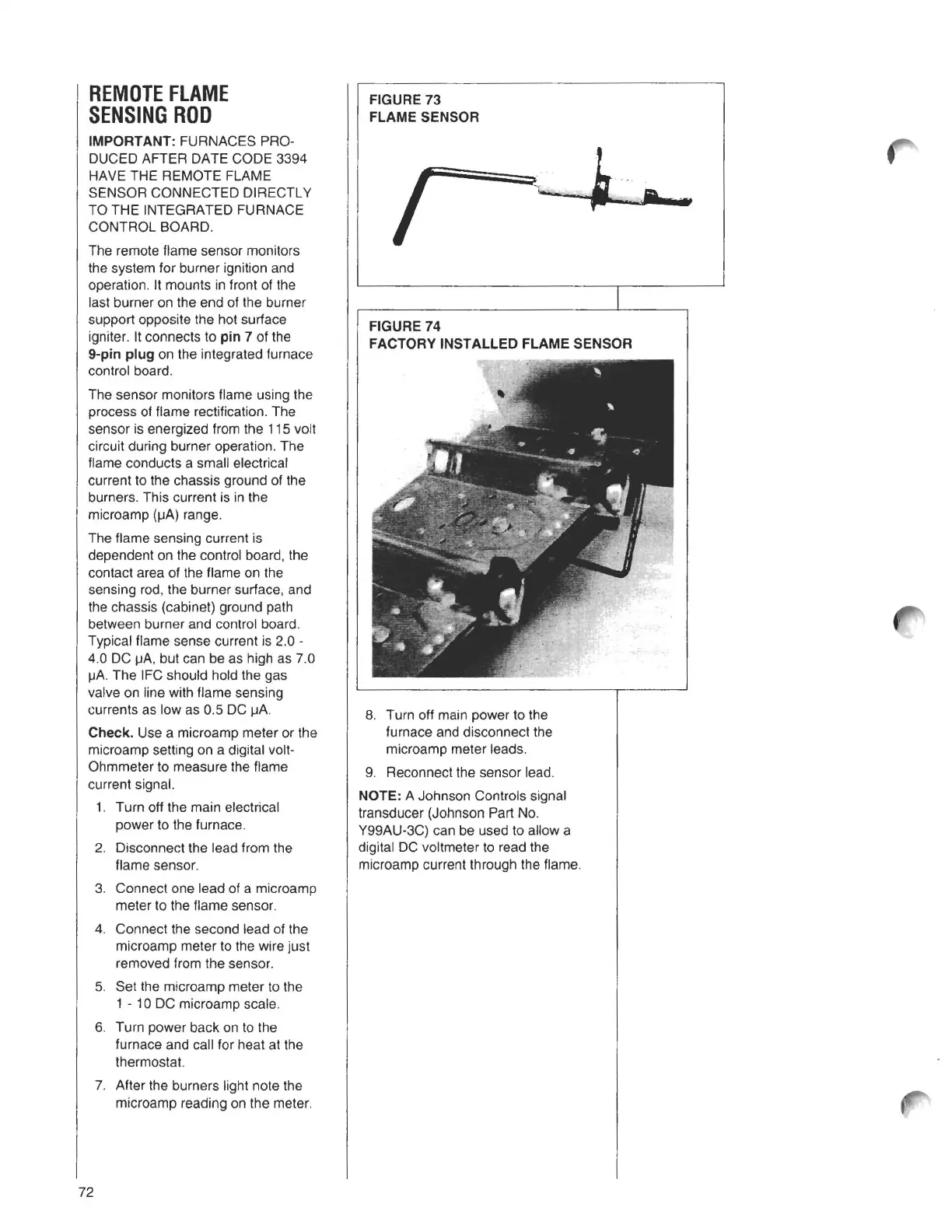

FIGURE 74

FACTORY INSTALLED FLAME SENSOR

8. Turn off main power to the

furnace and disconnect the

microamp meter leads.

9. Reconnect the sensor lead.

NOTE: A Johnson Controls signal

transducer (Johnson Part No.

Y99AU-3C) can be used to allow a

digital DC voltmeter to read the

microamp current through the flame.

72

Loading...

Loading...