NOTE:Some thermostats, such as

the Honeywell T8600, have a current

flow through the

W circuitry to

operate the thermostat. During the off

cycle this small load causes UTEC

830 and 831 furnace control boards

to try to start the furnace. Since the

load is so

weak,once the induced

draft blower starts, the draw on the

W circuit drops. However, this

causes the induced draft blower

motor to start and stop erratically.

Installing the 100 ohm, 10 watt

resistor from terminals "W" and

"C" solves this problem also.

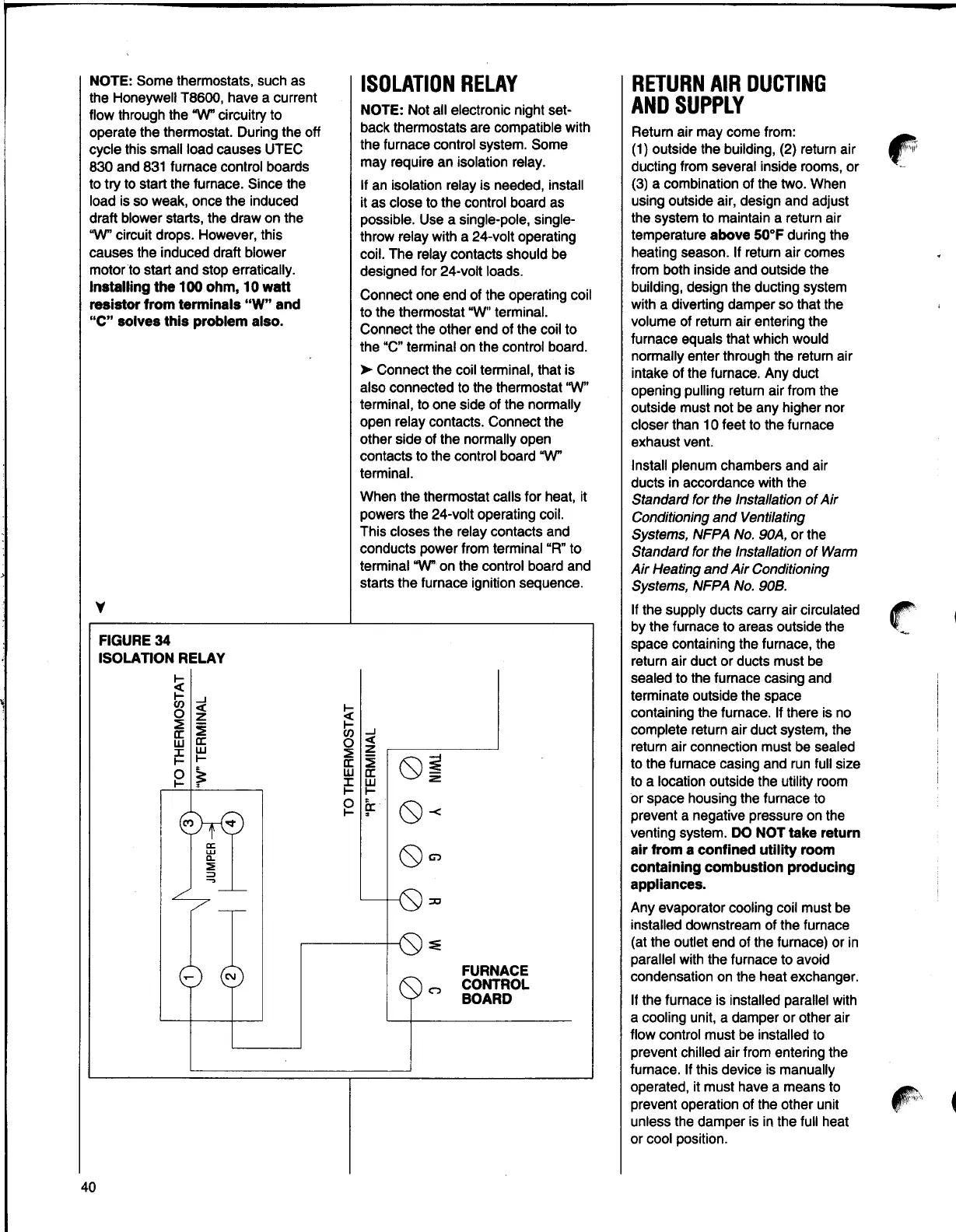

ISOLATIONRELAY

NOTE:Not all electronic night set-

back thermostats are compatible with

the furnace control system. Some

may require an isolation relay.

If an isolation relay is needed, install

it as close to the control board as

possible. Use a single-pole, single-

throw relay with a 24-volt operating

coil. The relay contacts should be

designed for 24-volt loads.

Connect one end of the operating coil

to the thermostat "W" terminal.

Connect the other end of the coil to

the "C" terminal on the control board.

►

Connect the coil terminal, that is

also connected to the thermostat

'W'

terminal, to one side of the normally

open relay contacts. Connect the

other side of the normally open

contacts to the control board

W

terminal.

When the thermostat calls for heat, it

powers the 24-volt operating coil.

This closes the relay contacts and

conducts power from terminal "R" to

terminal

W on the control board and

starts the furnace ignition sequence.

y

FIGURE34

ISOLATION RELAY

~

J

0

~

::? :E

a: a:

w w

i!: I-

~

~

I-

~

Cl)

0

::?

a:

w

J:

I-

0

I-

J

<(

z

:E

a:

w

I-

a:

.

0i

0

-<

cc

w

c..

::!:

=>

-,

0 C,

:::0

~

C\I

C")

FURNACE

CONTROL

BOARD

RETURNAIR DUCTING

AND SUPPLY

Return air may come from:

(1) outside the building, (2) return air

ducting from several inside rooms, or

(3) a combination of the two. When

using outside air, design and adjust

the system to maintain a return air

temperature

above 50°F during the

heating season. If return air comes

from both inside and outside the

building, design the ducting system

with a diverting damper so that the

volume of return air entering the

furnace equals that which would

normally enter through the return air

intake of the furnace. Any duct

opening pulling return air from the

outside must not be any higher nor

closer than 10 feet to the furnace

exhaust vent.

Install plenum chambers and air

ducts in accordance with the

Standard for the Installation of Air

Conditioning and Ventilating

Systems, NFPA No. 90A, or the

Standard for the Installation of Warm

Air Heating and Air Conditioning

Systems, NFPA No. 908.

If the supply ducts carry air circulated

by the furnace to areas outside the

space containing the furnace, the

return air duct or ducts must be

sealed to the furnace casing and

terminate outside the space

containing the furnace. If there is no

complete return air duct system, the

return air connection must be sealed

to the furnace casing and run full size

to a location outside the utility room

or space housing the furnace to

prevent a negative pressure on the

venting system.

DO NOT take return

air from a confined utility room

containing combustion producing

appliances.

Any evaporator cooling coil must be

installed downstream of the furnace

(at the outlet end of the furnace) or in

parallel with the furnace to avoid

condensation on the heat exchanger.

If the furnace is installed parallel with

a cooling unit, a damper or other air

flow control must be installed to

prevent chilled air from entering the

furnace. If this device is manually

operated, it must have a means to

prevent operation of the other unit

unless the damper is in the full heat

or cool position.

40

Loading...

Loading...