~

UTEC 1012-920/920A, 1028-927 and

-928 IFC BOARD TWINNING

INSTRUCTIONS

1. Single Stage Operation

a.

Ensure that both furnace 24

volt power supplies are in

phase.

b.

Connect furnace "ONE"

control board to the

thermostat.

C.

Connect the "C", "W", and

"TWIN" terminals on one

control to the "C", "W", and

"TWIN" terminals of the

second control respectively.

d.

Set DIP switch "3" to the

"TWIN" position on both

control boards.

e.

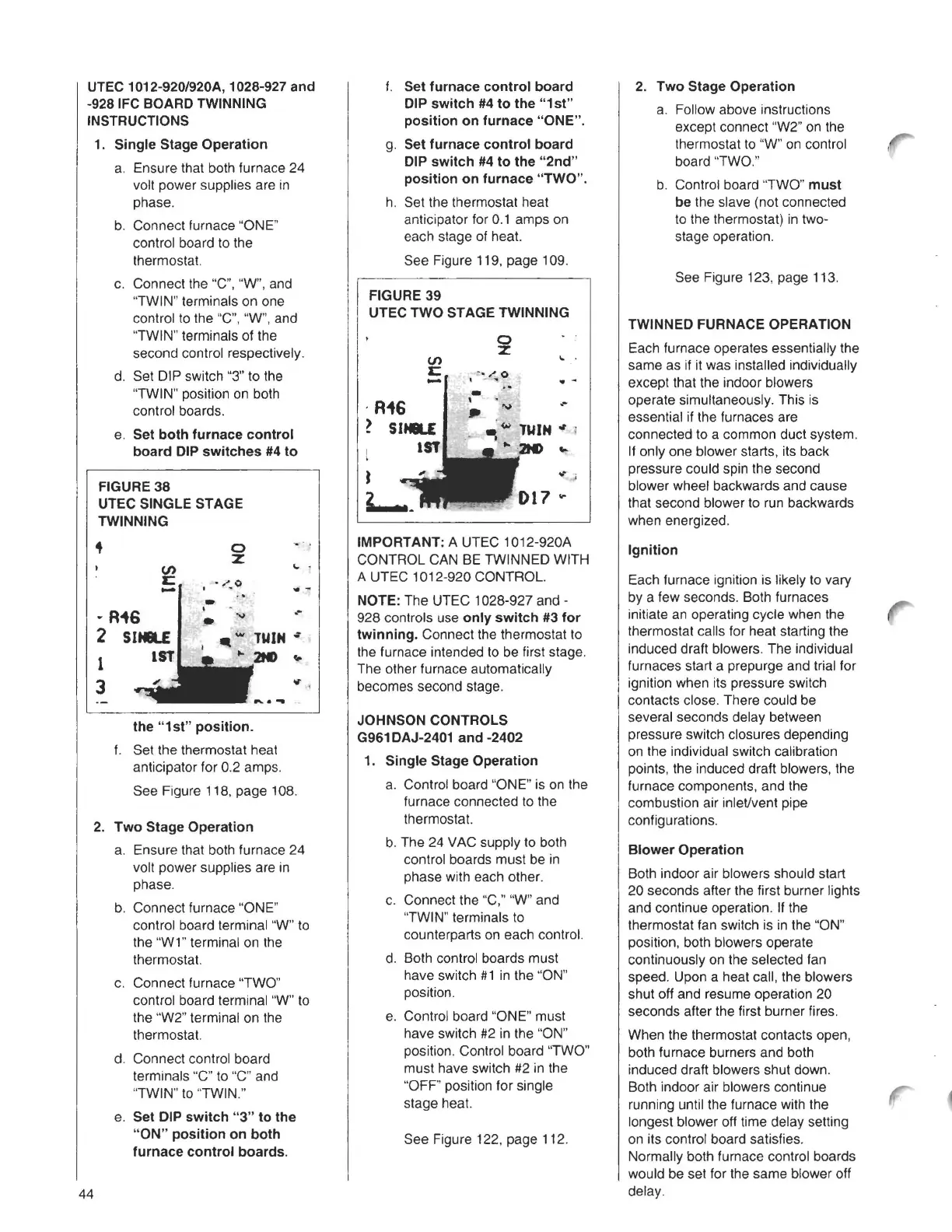

Set both furnace control

board DIP switches #4 to

FIGURE 38

UTEC SINGLE STAGE

TWINNING

..

0

z

..

CJ)

C

. ,.._o

-

..-

I

-

the "1st" position.

I.

Set the thermostat heat

anticipator for 0.2 amps.

See Figure 118, page 108.

2. Two Stage Operation

a.

Ensure that both furnace 24

volt power supplies are in

phase.

b.

Connect furnace "ONE"

control board terminal "W" to

the "W1" terminal on the

thermostat.

C.

Connect furnace 'TWO"

control board terminal "W" to

the "W2" terminal on the

thermostat.

d. Connect control board

terminals "C" to "C" and

'TWIN" to "TWIN."

e.

Set DIP switch "3" to the

"ON" position on both

furnace control boards.

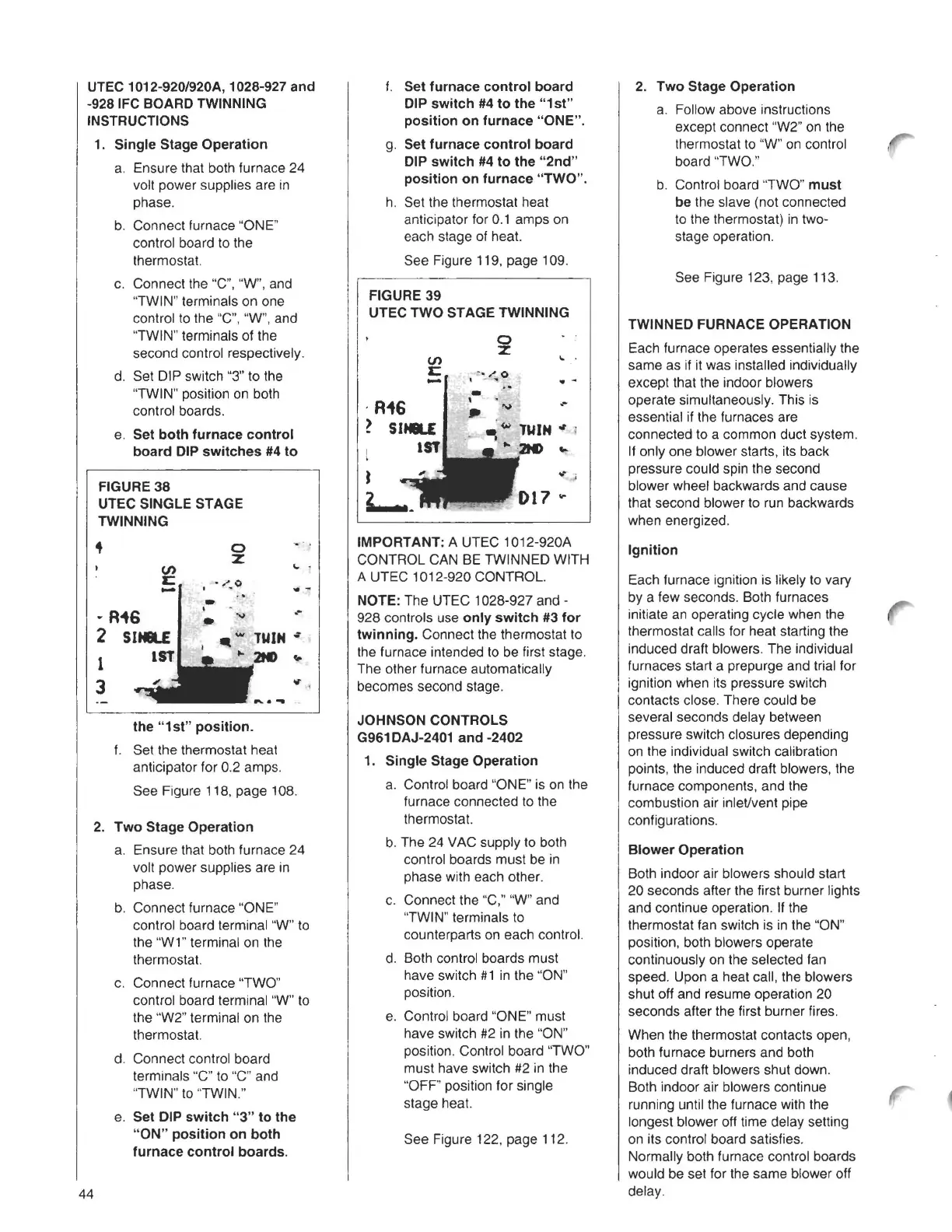

f. Set furnace control board

DIP switch #4 to the "1st"

position on furnace "ONE".

g. Set furnace control board

DIP switch #4 to the "2nd"

position on furnace "TWO".

h. Set the thermostat heat

anticipator for 0.1 amps on

each stage of heat.

See Figure 119, page 109.

FIGURE 39

UTEC TWO STAGE TWINNING

0

z

...

U)

C

-

.-

IMPORTANT: A UTEC 1012-920A

CONTROL CAN BE TWINNED WITH

A UTEC 1012-920 CONTROL.

NOTE: The UTEC 1028-927 and -

928 controls use

only switch #3 for

twinning.

Connect the thermostat to

the furnace intended to be first stage.

The other furnace automatically

becomes second stage.

JOHNSON CONTROLS

G961 DAJ-2401 and -2402

1. Single Stage Operation

a. Control board "ONE" is on the

furnace connected to the

thermostat.

b. The 24 VAC supply to both

control boards must be in

phase with each other.

c. Connect the "C," "W" and

"TWIN" terminals to

counterparts on each control.

d. Both control boards must

have switch #1 in the ''ON"

position.

e. Control board "ONE" must

have switch #2 in the "ON"

position. Control board "TWO"

must have switch #2 in the

"OFF' position for single

stage heat.

See Figure 122, page 112.

2. Two Stage Operation

a. Follow above instructions

except connect "W2" on the

thermostat to "W" on control

board "TWO."

b. Control board "TWO"

must

be

the slave (not connected

to the thermostat) in two-

stage operation.

See Figure 123, page 113.

TWINNED FURNACE OPERATION

Each furnace operates essentially the

same as if it was installed individually

except that the indoor blowers

operate simultaneously. This is

essential if the furnaces are

connected to a common duct system.

If only one blower starts, its back

pressure could spin the second

blower wheel backwards and cause

that second blower to run backwards

when energized.

Ignition

Each furnace ignition is likely to vary

by a few seconds. Both furnaces

initiate an operating cycle when the

thermostat calls for heat starting the

induced draft blowers. The individual

furnaces start a prepurge and trial for

ignition when its pressure switch

contacts close. There could be

several seconds delay between

pressure switch closures depending

on the individual switch calibration

points, the induced draft blowers, the

furnace components, and the

combustion air inleVvent pipe

configurations.

Blower Operation

Both indoor air blowers should start

20 seconds after the first burner lights

and continue operation. If the

thermostat fan switch is in the "ON"

position, both blowers operate

continuously on the selected fan

speed. Upon a heat call, the blowers

shut off and resume operation 20

seconds after the first burner fires.

When the thermostat contacts open,

both furnace burners and both

induced draft blowers shut down.

Both indoor air blowers continue

running until the furnace with the

longest blower off time delay setting

on its control board satisfies.

Normally both furnace control boards

would be set for the same blower off

delay.

44

Loading...

Loading...