• When the limit resets, the

inducer fan runs for 30 seconds

and stops. The main blower runs

for its off delay. After the main

blower stops, the inducer starts

and goes through a normal

ignition sequence.

3. HEAT ASSISTED LIMIT

CONTROL (HALC) OPENING

• The "self healing" feature shuts

down the gas valve, and keeps

the inducer running. If the next

trial for ignition fails, it starts the

main blower immediately. The

main blower runs for its off

delay. This should reset the

HALC. At the same time it goes

through up to four more normal

ignition trials and relights.

If it doesn't relight, the unit

locks out.

4. PRESSURE SWITCH

OPENING

• If the pressure switch opens

the gas valve immediately

closes. The induced draft blower

continues to run. If the pressure

switch contacts do not close, the

induced draft blower runs

indefinitely.

5. LOW/NO GAS PRESSURE

• With insufficient gas pressure

to generate a proper flame, the

control loses flame sensing and

goes into soft lock out.

6. IMPROPER POLARITY

• If the control or furnace is

wired improperly, the control

lights the burners, but cannot

sense the flame current. It goes

into soft lock out after 5 trials for

ignition.

7. VOLTAGE SPIKES

• Voltage spikes should have

no effect.

8. VARIATIONS IN 60 HERTZ

FREQUENCY

• The timing of the ignition

sequence changes in proportion

to the frequency variation.

9. MOMENTARY POWER

OUTAGES

• There are three outcomes from

a loss of power:

A. If the power interruption is

very short, the control does

not know power was lost and

continues what it was doing.

If the gas valve drops out, the

control senses loss of flame

and recycles.

B. If the power interruption is

long enough, it simulates an

open limit and the control

responds as such.

C. Power outages in between

cause a low voltage condition

at the microprocessor and the

unit fails a RAM check. This

results in a hard lock out.

10. CAN THE HONEYWELL

CONTROLS BE COMBINED

FOR TWINNING?

• A twinning kit for the Honeywell

S9201A1028 control is the

RXGP-F02 kit consisting of extra

blower door switches and wiring.

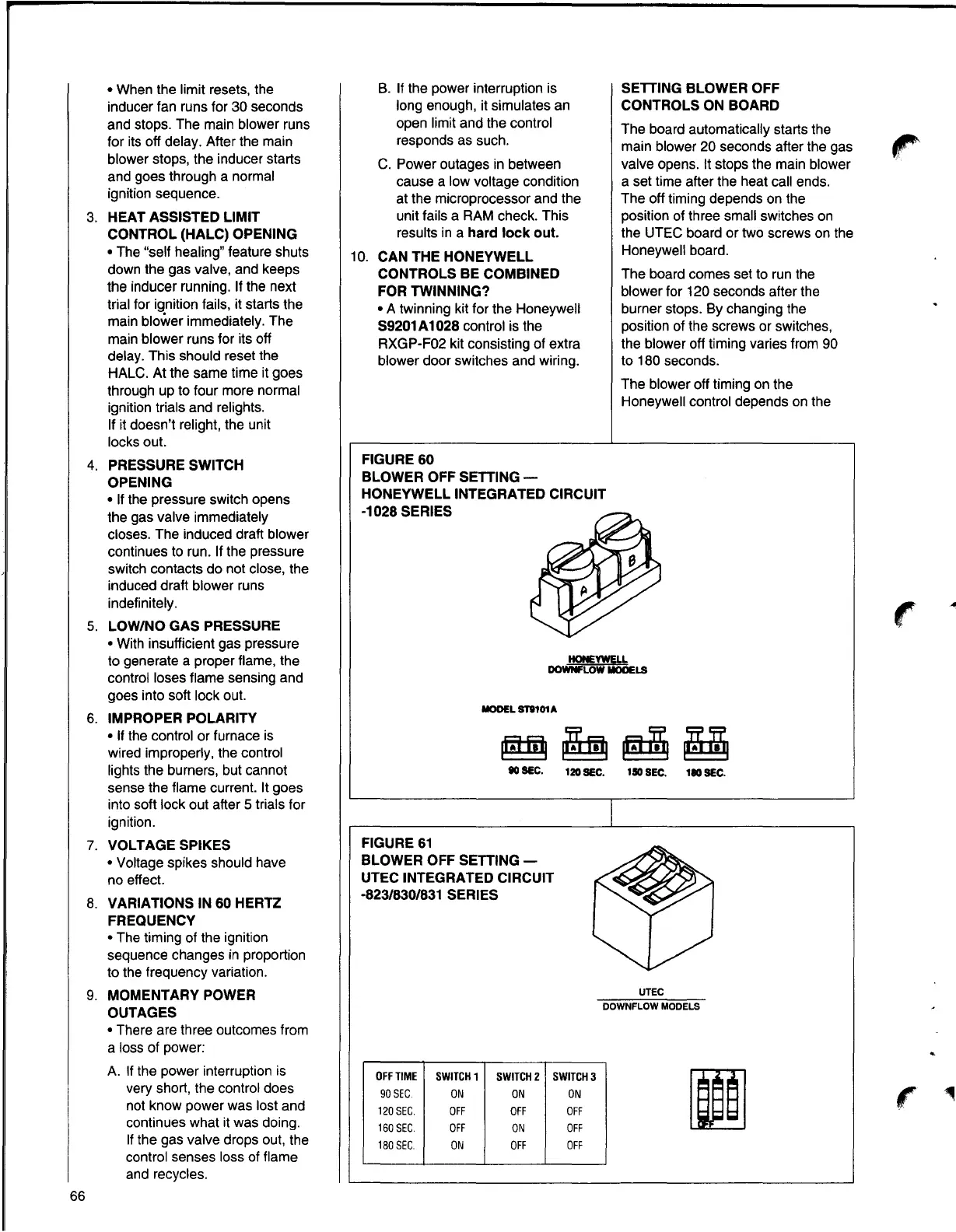

FIGURE60

BLOWER OFF SETTING -

HONEYWELL INTEGRATED CIRCUIT

-1028 SERIES

SETTING BLOWER OFF

CONTROLS ON BOARD

The board automatically starts the

main blower 20 seconds after the gas

valve opens. It stops the main blower

a set time after the heat call ends.

The off timing depends on the

position of three small switches on

the UTEC board or two screws on the

Honeywell board.

The board comes set to run the

blower for 120 seconds after the

burner stops. By changing the

position of the screws or switches,

the blower off timing varies from 90

to 180 seconds.

The blower off timing on the

Honeywell control depends on the

HONEVW£LL

DOWNFLOW MOOELS

MODEL STil101A

90 SEC. 120 SEC. 150 SEC. 180 SEC.

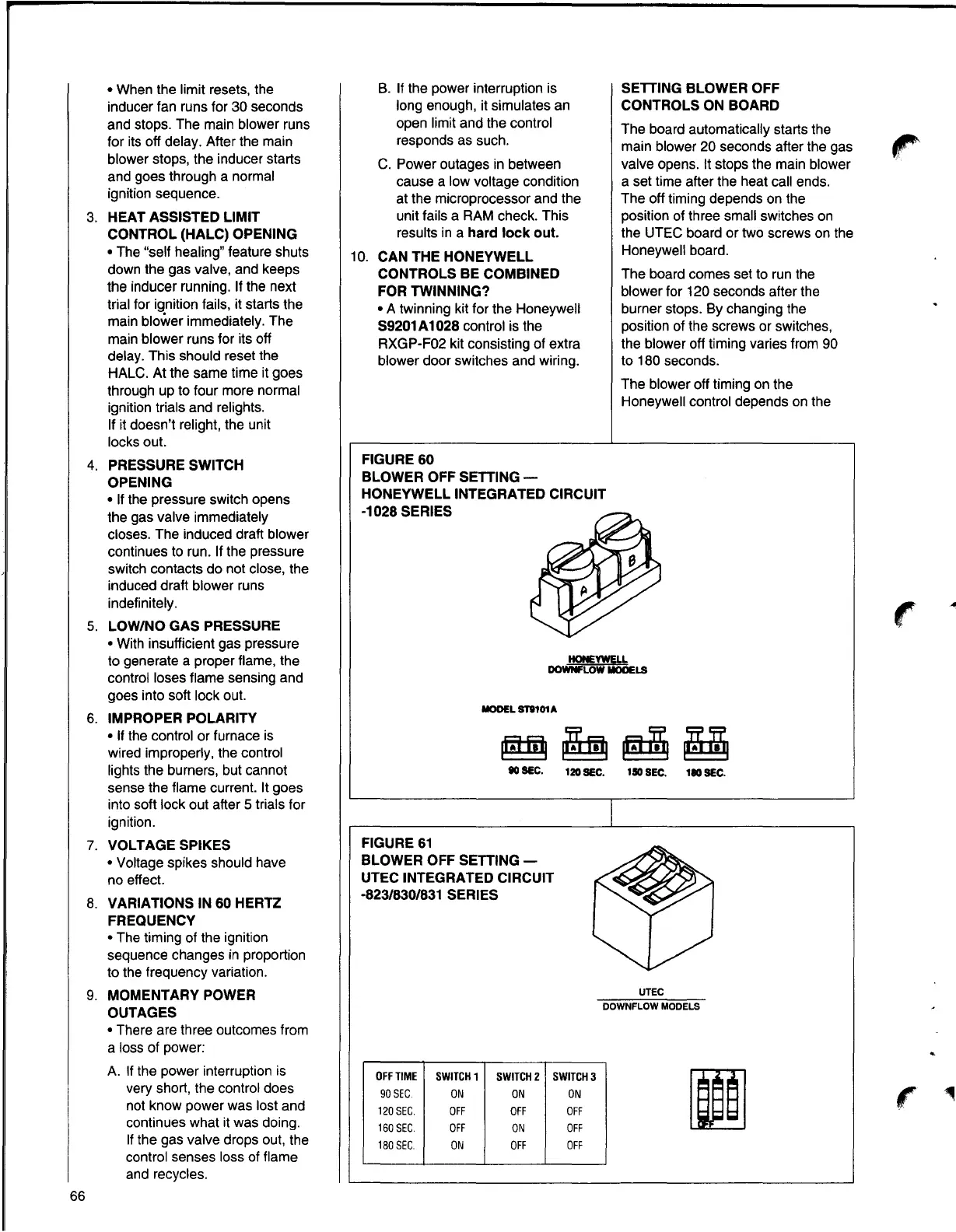

FIGURE 61

BLOWER OFF SETTING -

UTEC INTEGRATED CIRCUIT

-823/830/831 SERIES

r

r

....

r

UTEC

DOWNFLOW MODELS

OFF TIME SWITCH1

SWITCH2 SWITCH3

90 SEC. ON ON ON

120 SEC. OFF

OFF OFF

160 SEC. OFF

ON OFF

180 SEC. ON OFF OFF

66

Loading...

Loading...