SEQUENCE OF OPERATION

► Honeywell, JCI or UTEC

Integrated control with electronic

ignition

1. Each time the thermostat

contacts close the induced draft

blower runs for a 30-second

prepurge cycle.

2. The air proving negative

pressure switch closes.

3. After the 30 second prepurge,

EITHER the hot surface igniter

heats for 30 seconds to full

temperature, OR the direct spark

ignition electrodes spark.

4.

►

EITHER after the 30 second

hot surface igniter warm up, OR

when the electrodes begin

sparking, the gas valve opens for

an 8 - second trial for ignition.

5. The igniter lights the gas

burners. The igniter remains

energized for 7 seconds. During

the eighth second the control

checks for the presence of flame.

If flame is not sensed, the

system tries for a second

ignition. If this attempt fails the

control goes into a "self-healing"

mode for three minutes. It then

tries for ignition up to two times

more. If flame is not sensed, it

enters a one-hour soft lock out.

6. The main blower starts 22

seconds after the gas valve

opens.

FIGURE 36

ELECTRONIC IGNITION

GAS VALVE

7. When the thermostat cycle ends,

the gas valve closes, the burners

go out, the induced draft fan

stops and the negative pressure

switch opens.

8. The main blower continues until

timed off by the settings on the

integrated furnace control board.

FURNACETWINNING

A maximum of two furnaces may be

installed side by side on a common

duct system and operate as one, or

as first stage and second stage. The

twinning procedure makes both

furnace blowers operate together,

whether one or both furnaces are

firing. One thermostat can control

both units. This is necessary if the

two furnaces supply air for one 7-1/2

or 1

Oton single stage cooling

system.

To twin two furnaces, follow these

instructions and the twinning wiring

diagrams at the end of the service

manual.

IMPORTANT: ONLY TWIN

FURNACES WITH IDENTICAL

CONTROLS FROM THE SAME

MANUFACTURER OF CONTROL

BOARD.

NOTE: The "OK" LED flashes if the

twinning is not installed properly.

NOTE: Transformers of both

furnaces must be in phase.

HONEYWELL S9201 E2001 IFC

BOARD TWINNING INSTRUCTIONS

1. Single Stage Operation

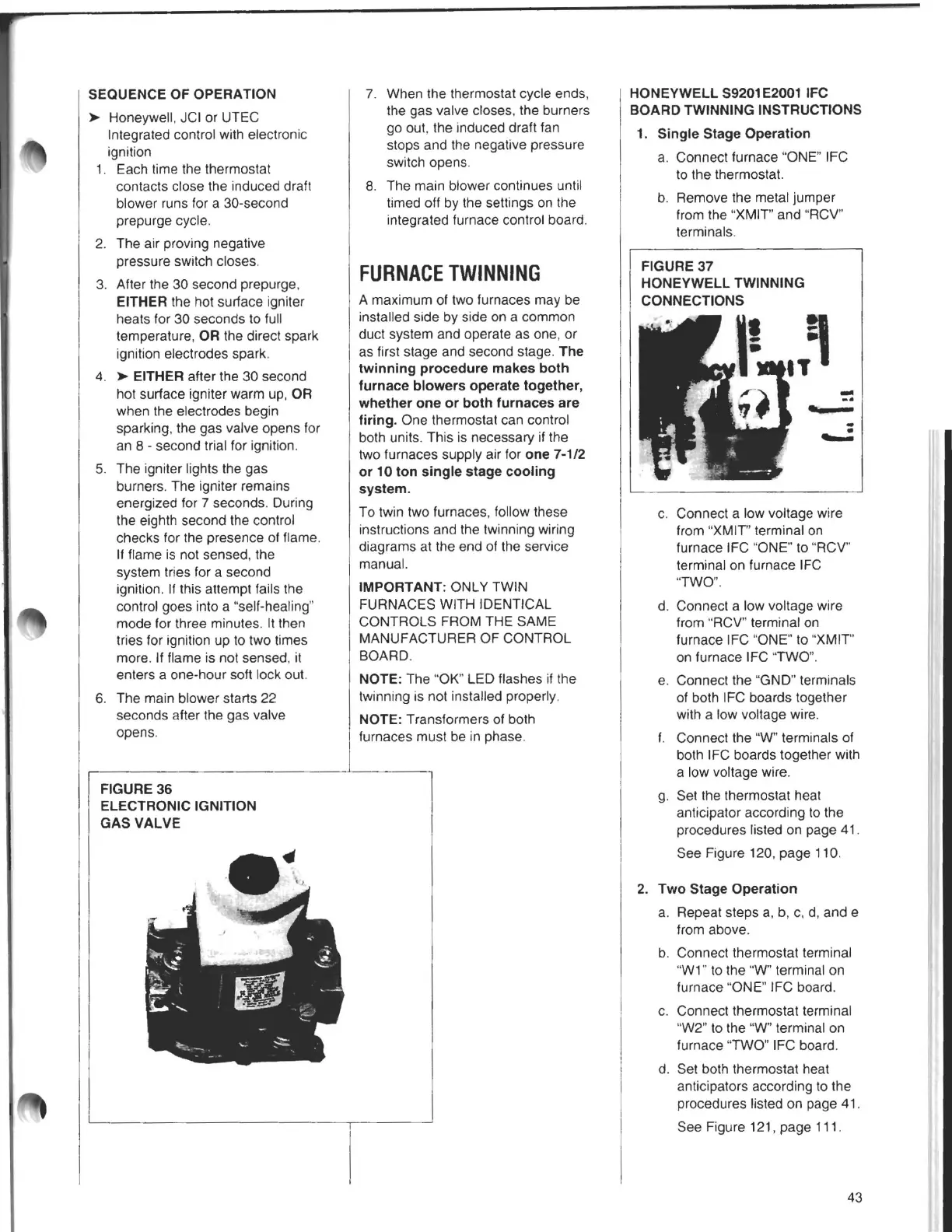

a. Connect furnace "ONE" IFC

to the thermostat.

b. Remove the metal jumper

from the "XMIT" and "RCV"

terminals.

FIGURE 37

HONEYWELL TWINNING

CONNECTIONS

-

-·

C.

Connect a low voltage wire

from "XMIT" terminal on

furnace IFC "ONE" to "RCV"

terminal on furnace IFC

"TWO".

d. Connect a low voltage wire

from "RCV" terminal on

furnace IFC "ONE" to "XMIT"

on furnace IFC "TWO".

e. Connect the "GND" terminals

of both IFC boards together

with a low voltage wire.

t. Connect the "W" terminals of

both IFC boards together with

a low voltage wire.

g.

Set the thermostat heat

anticipator according to the

procedures listed on page 41 .

See Figure 120, page 110.

2. Two Stage Operation

a. Repeat steps a, b, c, d, and e

from above.

b. Connect thermostat terminal

"W1" to the

"W"terminal on

furnace "ONE" IFC board.

C. Connect thermostat terminal

"W2" to the "W" terminal on

furnace "TWO" IFC board.

d. Set both thermostat heat

anticipators according to the

procedures listed on page 41.

See Figure 121, page 111.

43

Loading...

Loading...