SERVICEAND TROUBLESHOOTING

A WARNING: THE ABILITY TO

PROPERLY PERFORM SERVICE

ON THIS EQUIPMENT REQUIRES

CERTAIN EXPERTISE, MECHAN-

ICAL SKILLS, TOOLS AND TEST

EQUIPMENT. IF YOU DO NOT

POSSESS THESE, DO NOT

ATTEMPT TO PERFORM ANY

MAINTENANCE ON THIS EQUIP-

MENT OTHER THAN THOSE

PROCEDURES RECOMMENDED IN

THE USER'S MANUAL. A FAILURE

TO FOLLOW THIS WARNING

COULD RESULT IN POSSIBLE

DAMAGE TO THE EQUIPMENT,

SERIOUS PERSONAL INJURY,

OR DEATH.

The

HVAC industry, like the auto

industry, is faced with increasing

goverment imposed efficiency

regulations. New and more

sophisticated mechanical means for

achieving higher efficiencies have

been engineered. Gone are the days

when all a person needed to work on

an auto was just a wrench and

screwdriver. The same is true with

heating and cooling equipment. The

use of test equipment is now more

critical than ever.

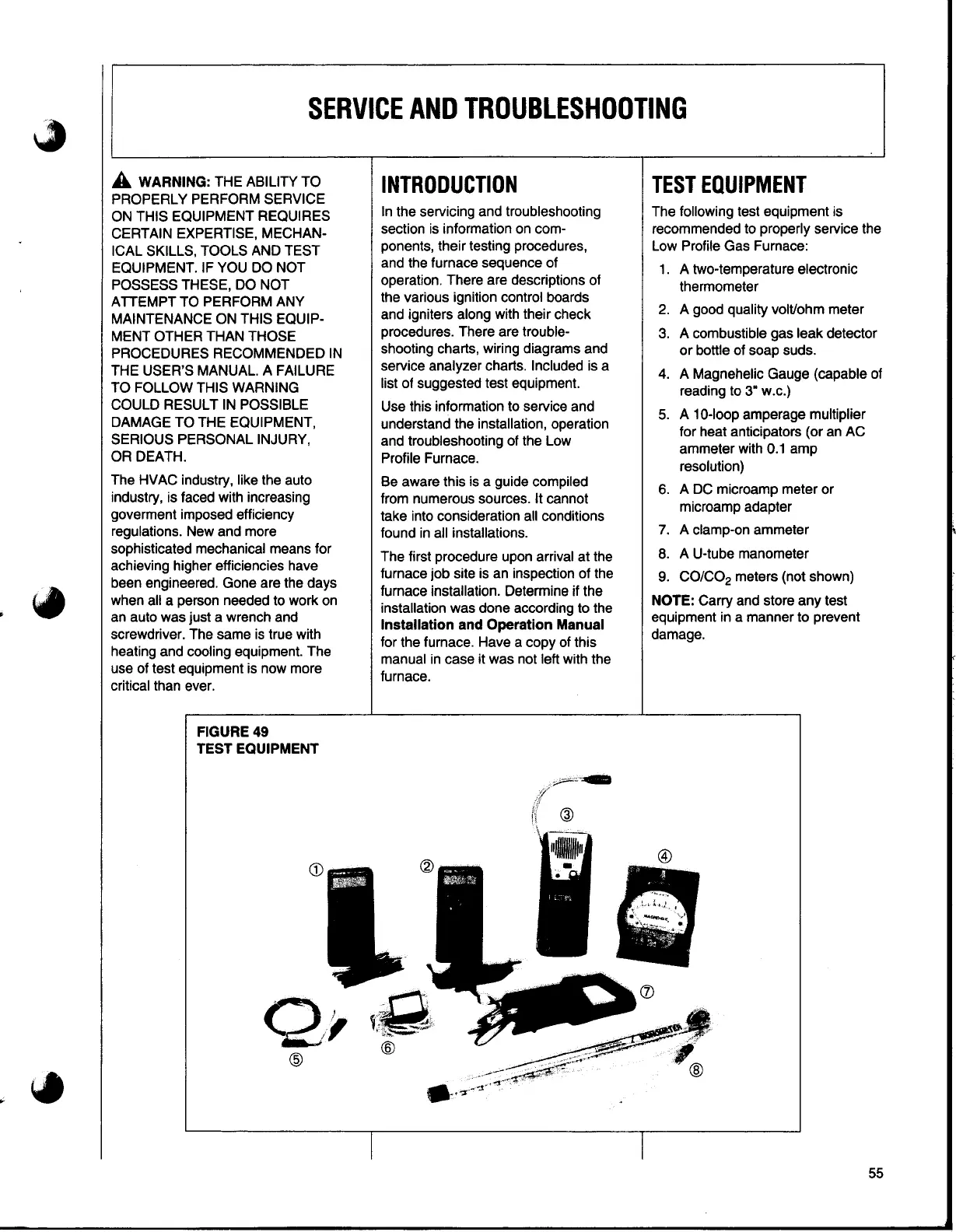

FIGURE49

TEST EQUIPMENT

INTRODUCTION

In the servicing and troubleshooting

section is information on com-

ponents, their testing procedures,

and the furnace sequence of

operation. There are descriptions of

the various ignition control boards

and igniters along with their check

procedures. There are trouble-

shooting charts, wiring diagrams and

service analyzer charts. Included is a

list of suggested test equipment.

Use this information to service and

understand the installation, operation

and troubleshooting of the Low

Profile Furnace.

Be aware this is a guide compiled

from numerous sources. It cannot

take into consideration all conditions

found in all installations.

The first procedure upon arrival at the

furnace job site is an inspection of the

furnace installation. Determine if the

installation was done according to the

Installation and Operation Manual

for the furnace. Have a copy of this

manual in case it was not left with the

furnace.

TESTEQUIPMENT

The following test equipment is

recommended to properly service the

Low Profile Gas Furnace:

1. A two-temperature electronic

thermometer

2. A good quality volVohm meter

3. A combustible gas leak detector

or bottle of soap suds.

4. A Magnehelic Gauge (capable of

reading to 3" w.c.)

5. A 10-loop amperage multiplier

for heat anticipators (or an AC

ammeter with 0.1 amp

resolution)

6. A DC microamp meter or

microamp adapter

7. A clamp-on ammeter

8. A U-tube manometer

9. CO/CO

2

meters (not shown)

NOTE: Carry and store any test

equipment in a manner to prevent

damage.

55

Loading...

Loading...