this assembly. Locate the ground-

joint union in accordance with all

applicable codes.

Install a drip leg in

the gas supply line as close to the

furnace as possible. Use a pipe

compound resistant to the action of

LP gases on all threaded pipe

connections.

Install gas piping in accordance with

local codes and utility company

regulations. Consult the local gas

company for location of a manual

main valve.

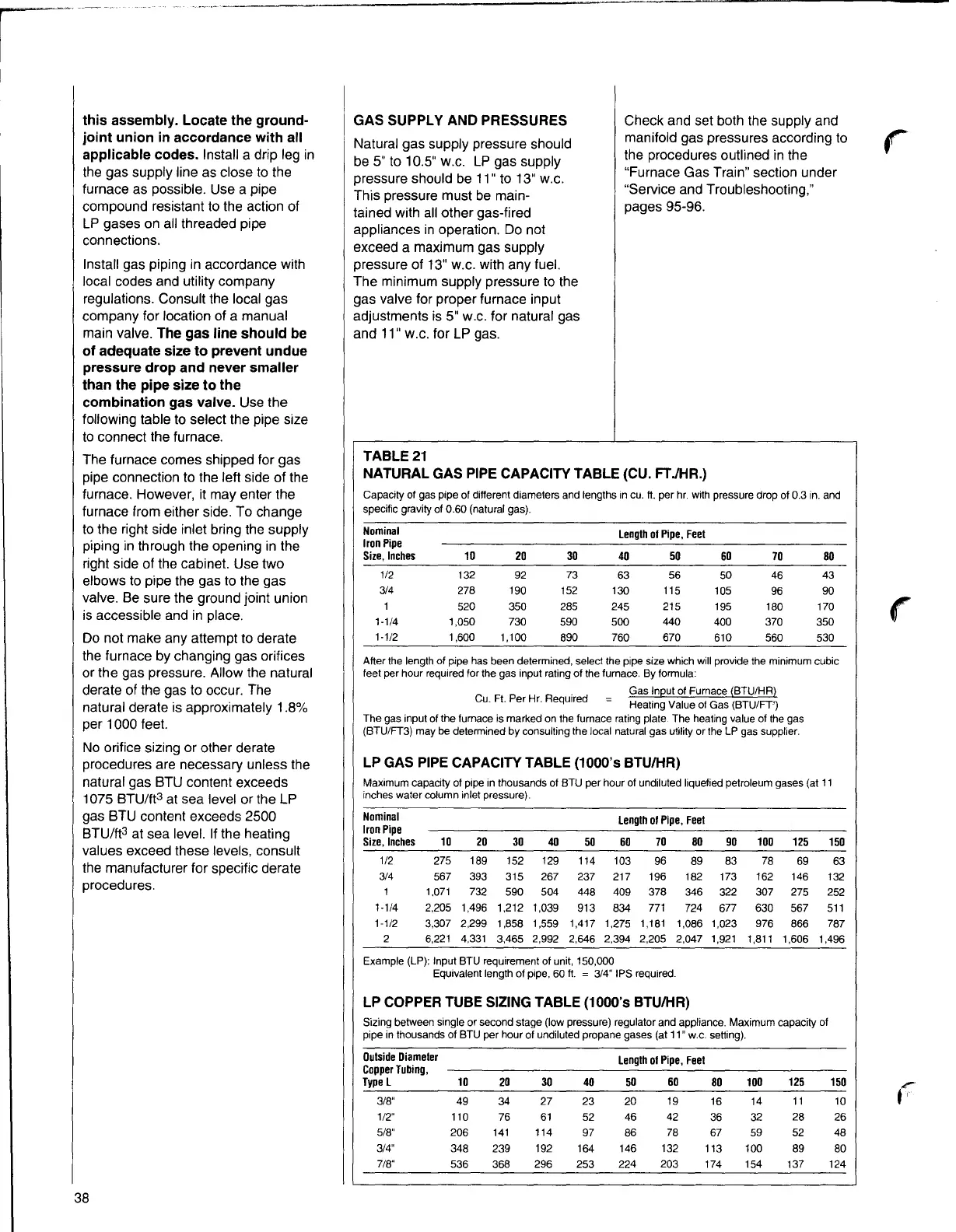

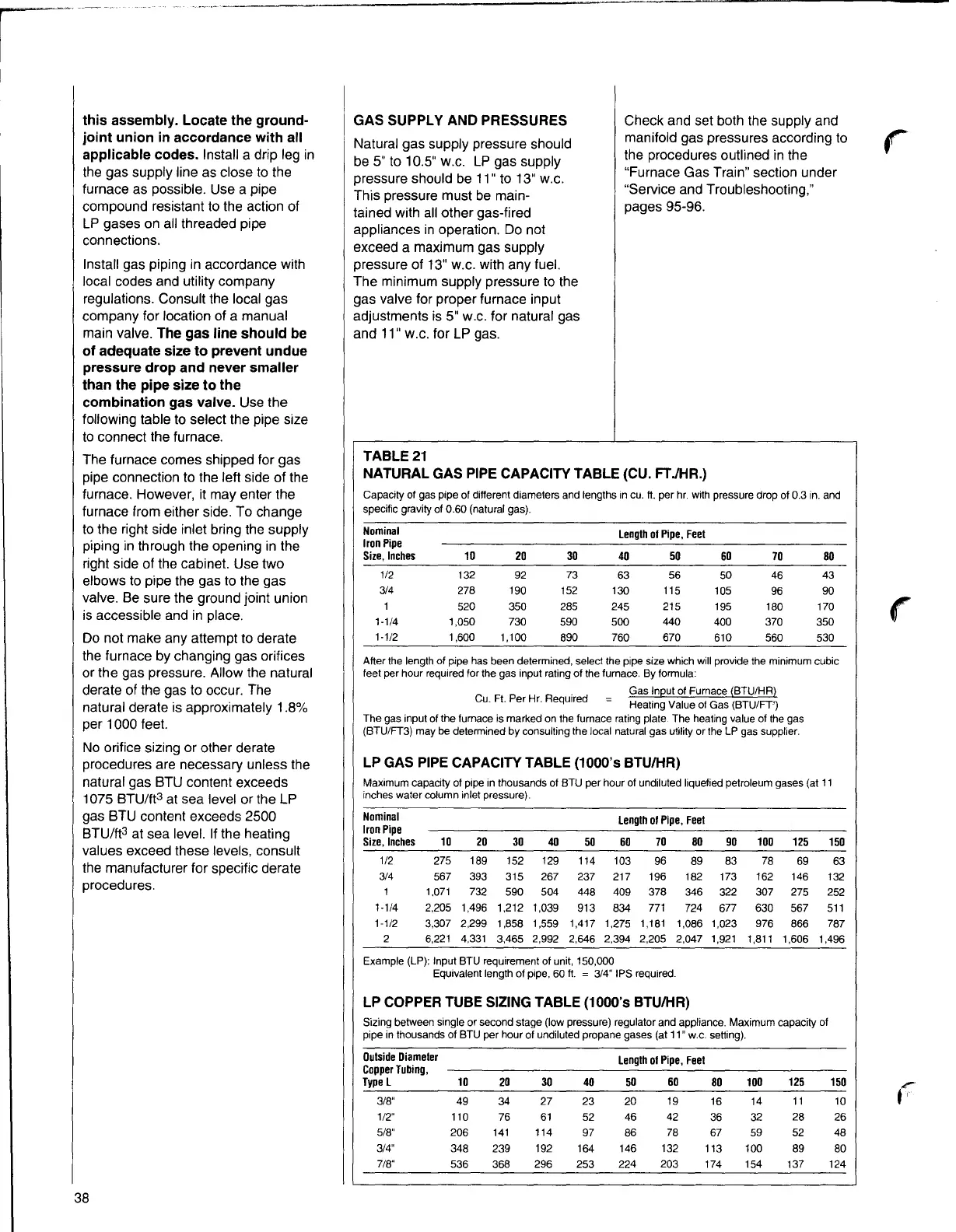

The gas line should be

of adequate size to prevent undue

pressure drop and never smaller

than the pipe size to the

combination gas valve.

Use the

following table to select the pipe size

to connect the furnace.

The furnace comes shipped for gas

pipe connection to the left side of the

furnace. However, it may enter the

furnace from either side. To change

to the right side inlet bring the supply

piping in through the opening in the

right side of the cabinet. Use two

elbows to pipe the gas to the gas

valve. Be sure the ground joint union

is accessible and in place.

Do not make any attempt to derate

the furnace by changing gas orifices

or the gas pressure. Allow the natural

derate of the gas to occur. The

natural derate is approximately 1.8%

per 1 000 feet.

No orifice sizing or other derate

procedures are necessary unless the

natural gas BTU content exceeds

1075 BTU/ft

3

at sea level or the LP

gas BTU content exceeds 2500

BTU/ft

3

at sea level. If the heating

values exceed these levels, consult

the manufacturer for specific derate

procedures.

GAS SUPPLY AND PRESSURES

Natural gas supply pressure should

be 5" to 10.5" w.c. LP gas supply

pressure should be 11" to 13" w.c.

This pressure must be main-

tained with all other gas-fired

appliances in operation. Do not

exceed a maximum gas supply

pressure of 13" w.c. with any fuel.

The minimum supply pressure to the

gas valve for proper furnace input

adjustments is 5" w.c. for natural gas

and 11" w.c. for LP gas.

TABLE 21

Check and set both the supply and

manifold gas pressures according to

the procedures outlined in the

"Furnace Gas Train" section under

"Service and Troubleshooting,"

pages 95-96.

r

NATURAL GAS PIPE CAPACITY TABLE (CU. FT JHR.)

Capacity of gas pipe of different diameters and lengths in cu. ft. per hr. with pressure drop of 0.3 in. and

specific gravity of 0.60 (natural gas).

Nominal

Iron Pipe

Lengthof Pipe, Feet

Size, Inches

10 20 30 40 50 60

70 80

1/2

132 92

73

63

56 50 46 43

3/4 278 190

152

130 115

105

96

90

520

350

285 245 215 195 180 170

1-1/4 1,050 730

590 500

440

400 370 350

1-1/2 1,600 1,100

890 760 670

610 560 530

After the length of pipe has been determined, select the pipe size which will provide the minimum cubic

feet per hour required for the gas input rating of the furnace. By formula:

Gas Input of Furnace (BTU/HR)

Cu. Ft. Per Hr. Required

Heating Value of Gas (BTU/FT')

The gas input of the furnace is marked on the furnace rating plate. The heating value of the gas

(BTU/FT3) may be determined by consulting the local natural gas utility or the LP gas supplier.

LP GAS PIPE CAPACITY TABLE (1000's BTU/HR)

Maximum capacity of pipe in thousands of BTU per hour of undiluted liquefied petroleum gases (at 11

inches water column inlet pressure).

Nominal

Lengthol Pipe, Feet

Iron Pipe

Size, Inches

10 20 30 40

50 60

70 80 90 100 125

150

1/2 275 189 152 129

114 103 96 89 83 78 69

63

3/4 567 393 315

267 237 217 196 182

173 162

146 132

1 1,071 732

590 504 448 409 378 346 322 307 275 252

1-1/4 2,205

1,496 1,212 1,039

913 834

771 724

677 630 567 511

1-1/2

3,307 2,299 1,858 1,559 1,417 1,275 1,181 1,086 1,023 976

866

787

2 6,221

4,331

3,465 2,992 2,646 2,394 2,205 2,047 1,921

1,811 1,606 1,496

Example {LP): Input BTU requirement of unit, 150,000

Equivalent length of pipe, 60 ft.

= 3/4" IPS required.

LP COPPER TUBE SIZING TABLE (1000's BTU/HR)

Sizing between single or second stage (low pressure) regulator and appliance. Maximum capacity of

pipe in thousands of BTU per hour of undiluted propane gases (at 11" w.c. setting).

OutsideDiameter

CopperTubing,

Lengthof Pipe, Feet

Type

L

10 20 30 40 50 60

80

100 125 150

3/8"

49 34 27

23

20 19 16 14 11 10

1/2" 110

76 61 52 46

42

36

32

28

26

5/8" 206 141 114

97 86

78

67 59 52 48

3/4"

348

239

192 164 146 132 113 100

89 80

7/8"

536 368 296 253 224 203 174 154 137 124

f

r-

1

38

Loading...

Loading...