VALVE GUIDES

INSPECTION

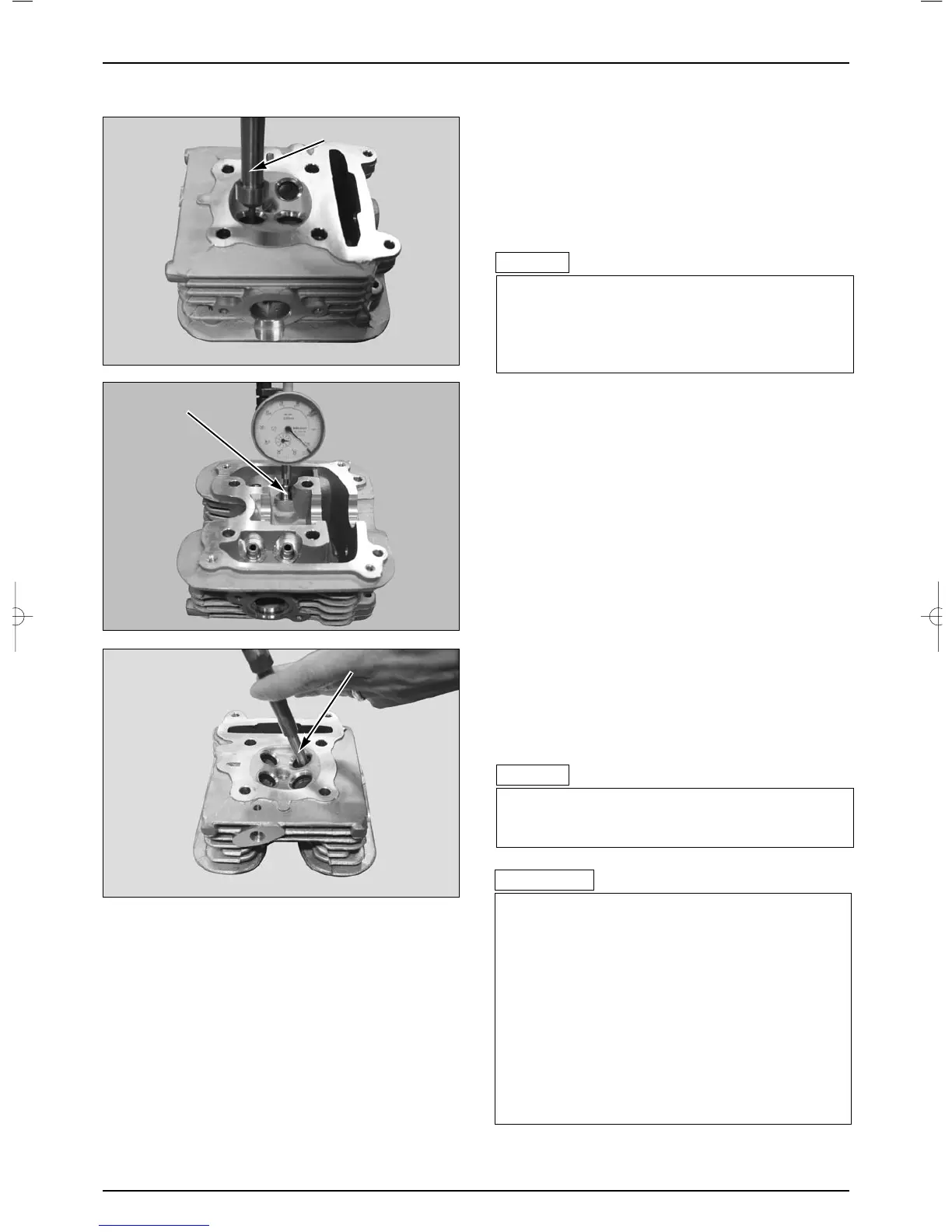

● Insert the valve guide reamer from the combustion

chamber side and ream the guide to remove any carbon

build-up before measuring the guide.

TOOL : VALVE GUIDE REAMER

● Measure and record each valve guide inner diameter.

SERVICE LIMIT : 5.030 mm

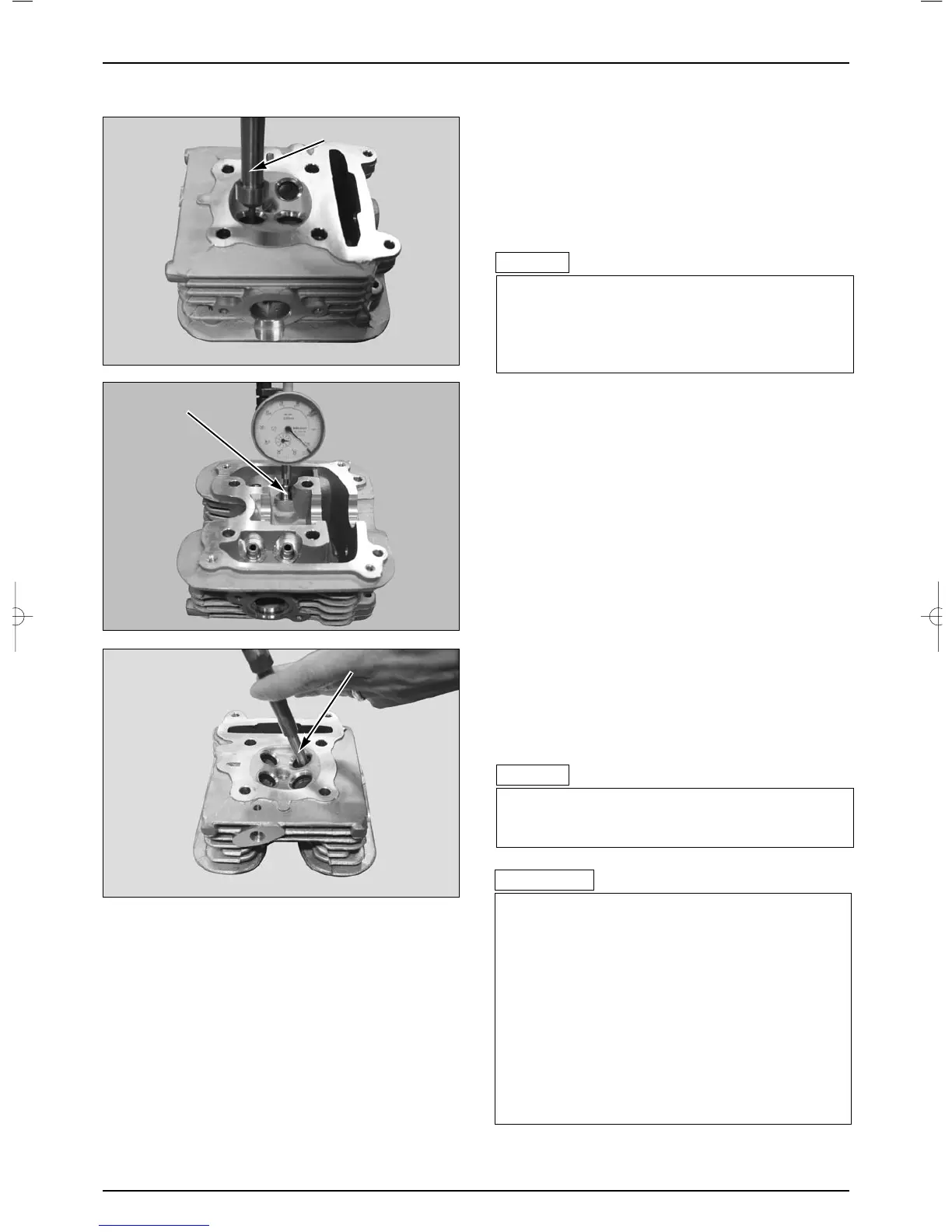

● Measure the guide-to-stem clearance with a dial

indicator while rocking the stem in the direction of

normal thrust.

SERVICE LIMIT : IN : 0.090 mm

EX: 0.120 mm

● Measure the inner diameter of the new valve guide. If

the clearance is not within the service limit, replace the

valve.

REPLACEMENT

● Heat the cylinder head to 130°C - 140°C (275°F - 290°F).

● Support the cylinder head and drive the old guides out

of the combustion chamber side of the cylinder head.

TOOL : VALVE GUIDE DRIVER

10-7

CYLINDER HEAD / VALVES

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE REAMER

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

VALVE GUIDE DRIVER

●Take care not to tilt or lean the reamer in the guide

while reaming.

●Rotate the reamer clockwise, never counterclockwise

when inserting and removing.

!

NOTE

△

●Avoid damaging the head when driving the valve

giude out.

!

NOTE

△

●Do not heat the cylinder head beyond 150°C (300°F).

●Use temperature indicator sticks, available from

welding supply stores, to be sure the cylinder head is

heated to the proper temperature.

●Using a torch to heat the cylinder head may cause

warping.

●Wear insulated gloves to avoid burns when handling

the heated cylinder head.

●Refinish the valve seats whenever the valve guides are

replaced to prevent uneven seating.

!

CAUTION

△

Loading...

Loading...