WARPAGE INSPECTION

● Check the cylinder for warpage by placing a straight

edge and feeler gauge across the stud holes. Replace

the cylinder if the service limit is exceeded.

SERVICE LIMIT : 0.02 mm

PISTON / PISTON RING

REMOVAL

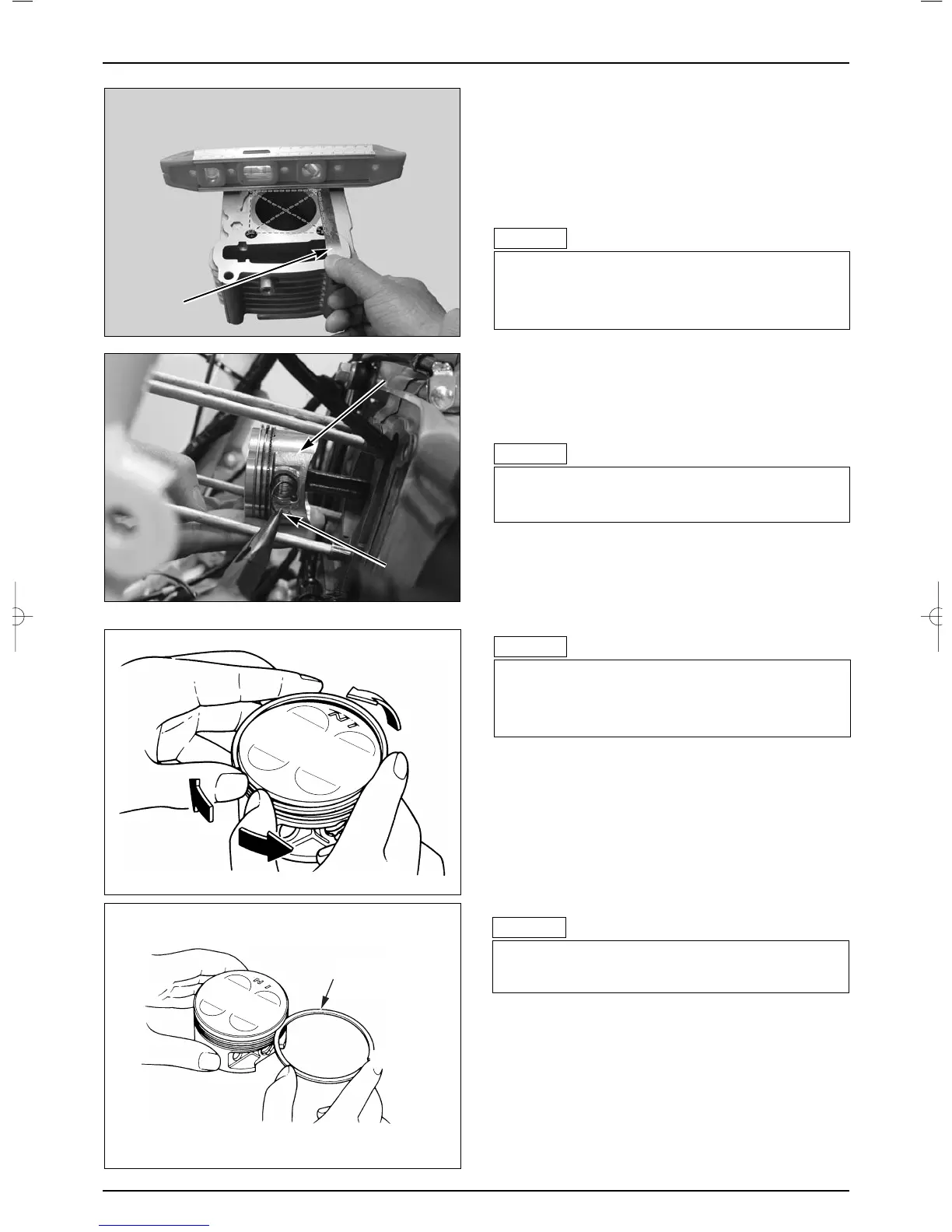

● Remove the piston pin clip using a pair of pliers.

● Press the piston pin out of the piston.

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

PISTON PIN CLIP

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

FEELER GAUGE

●Any clearance between the cylinder and head due to

damage or warpage will result in compression leaks

and reduced performance.

!

NOTE

△

●Place a clean shop towel over the crankcase to prevent

the possibility of the clip falling into the crankcase.

!

NOTE

△

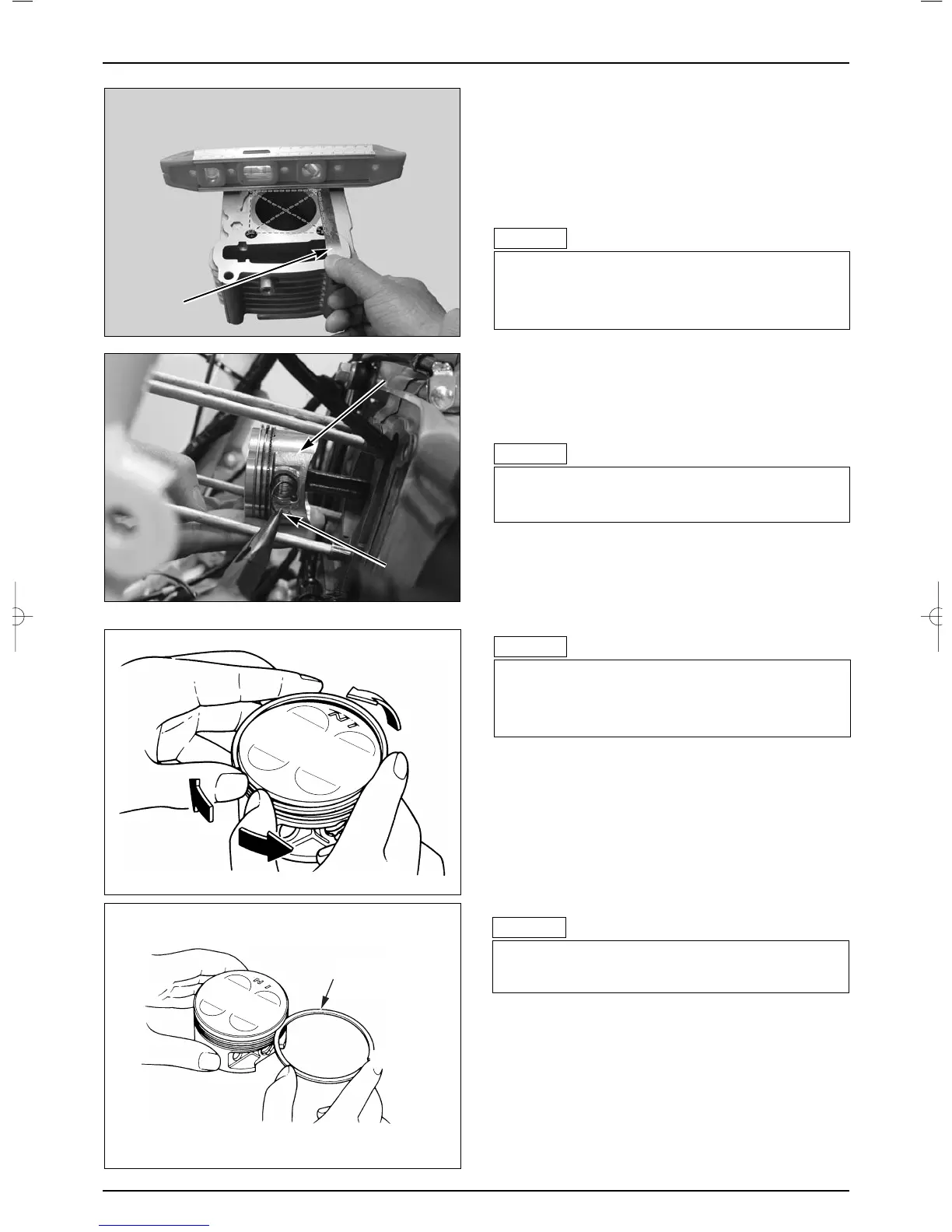

●Do not damage or scratch the piston.

●Do not apply side force to the connecting rod.

●Do not let the clip fall into the crankcase.

!

NOTE

△

●Do not damage to the piston by piston ring when

removing.

!

NOTE

△

● Measure the clearance between the piston ring and

piston grooves.

SERVICE LIMIT : TOP : 0.110 mm

SECOND : 0.080 mm

OIL RING : 0.280 mm

● Inspect the piston for wear or damage.

INSPECTION

● Clean carbon deposits from the piston.

● Inspect the piston rings for movement by pressing the

rings. The rings should be able to move in its groove

without catching.

● Spread each piston ring and remove it by lifting it up at

a point just opposite the gap.

PISTON RING

Loading...

Loading...