Figure 4-214 Spring Pin Identification

3. Replaceanydefectivespringpins(bentpinheadorinconsistentheightontopwithothers)withnew

ones.Onlydothiswhenabsolutelynecessary.Whenremovingthespringpins,usesmallneedle-nose

pliersandgentlypullstraightupwithnolateralmovement.

NOTE

Donotattempttostraightenorrepairanydamagedspringpins.Thedefectivepinsmustbereplaced.

4. DiscardthedefectivespringpinsandinspecttheInverterforanyforeignobjects.

5. Insertthenewspringpinscarefullyandverifytheylineupinthenotches.RefertoFigure4-212Seated

SpringPinsonpage190.

6. RetrievethenewDriverBoardfromthepackaging.

NOTE

Useextremecarewhenremovingthenewdriverboardandcoverfromthepackaging.Thecoversnapsintoplaceoverthedriverboard

butcouldseparate.Besuretoholdbothtoavoiddroppingthedriverboardifseparationoccurs.Iftheydobecomeseparated,carefully

snapthecoverbackintoplacepriortoassembly.

7. Forproperalignment,inserttwo(2)ofthefastenersinoppositecornersoftheDriverBoard.

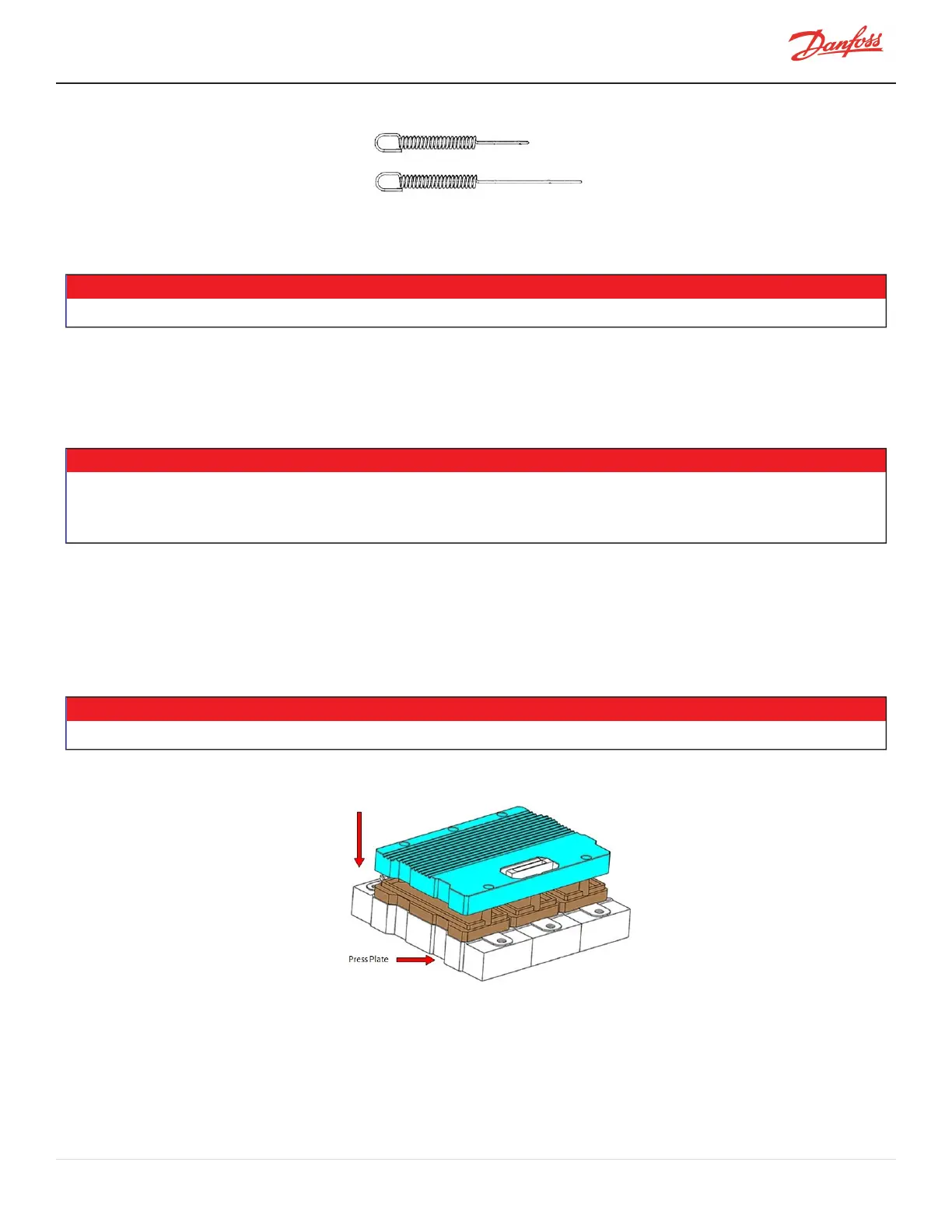

8. AlignthenewDriverBoardovertheInvertermodulewiththeconnectortowardsthemotoroutputbus

bar(theshapeofDriverBoardmustbealignedwithInverterPressPlateshape).RefertoFigure4-215

DriverBoardPlacementforthenexttwo(2)steps.

9. LowertheDriverBoarddownontheInvertermodule,donotallowforanylateralmovement.Besure

thebottomoftheDriverBoardisparallelwiththePressPlate.

• • • CAUTION • • •

Anylateralmovementmaydamagethespringpins.

Figure 4-215 Driver Board Placement

10. InserttheremainingfastenersandtightenfromcenteroutwardaccordingtoFigure4-216Initial

TighteningPassSequenceonpage192.Thiswillbethefirstpassandthefastenersshouldonlybe

snugandnottorquedatthisstep.

M-SV-001-EN Rev. H-1/23/2023 Page 191 of 294

Loading...

Loading...