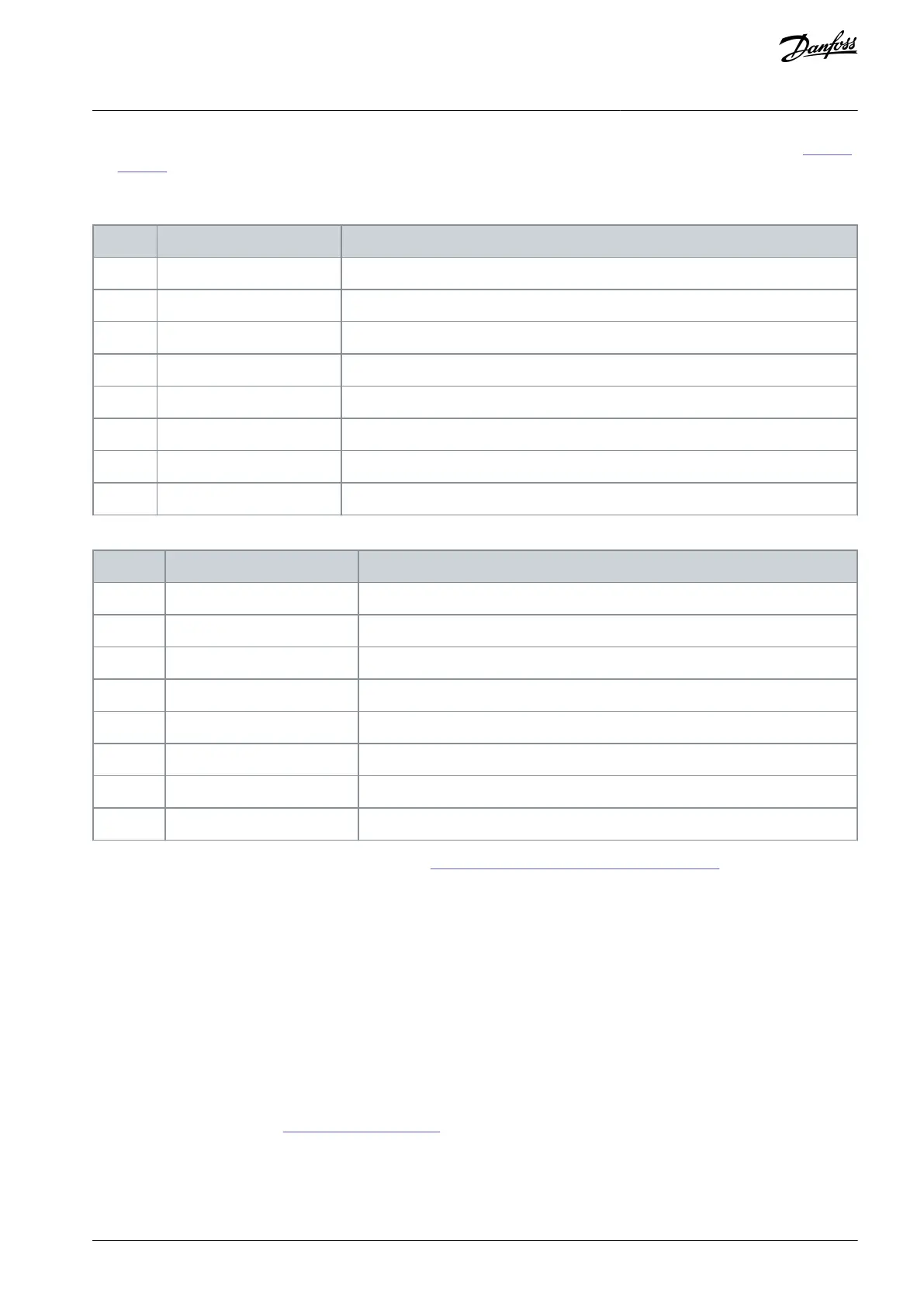

The Status and Control Bytes, which are used to indicate, monitor and set the safety status of the F-Device are described in Table 44

and Table 45. For more details, refer to PROFIsafe – Profile for Safety Technology on PROFIBUS DP and PROFINET IO Technical Speci-

fication.

Table 44: Description of PROFIsafe Status Byte

Communication fault: Watchdog timeout

Fail-safe values (FV) activated

Consecutive number has been reset

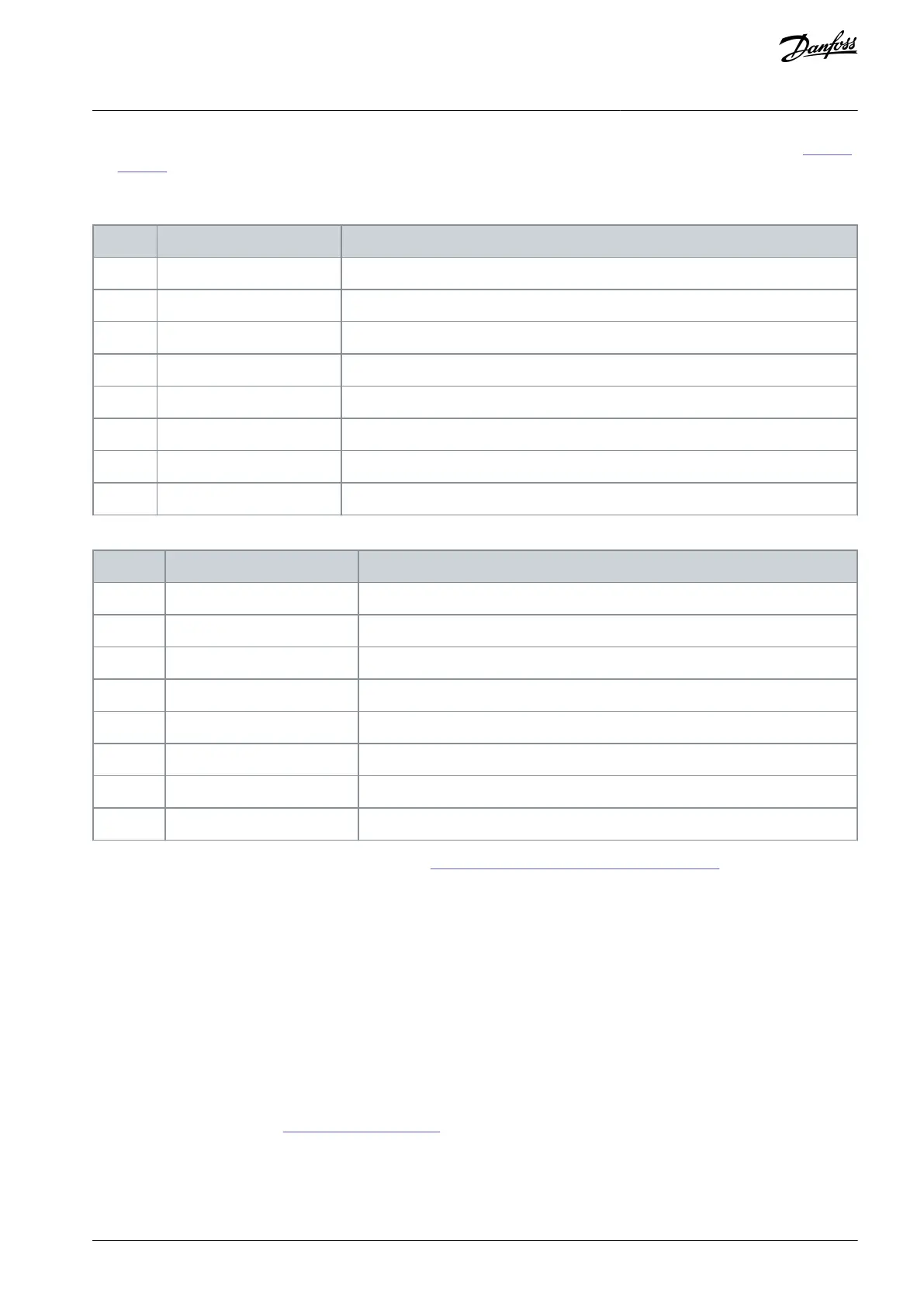

Table 45: Description of PROFIsafe Control Byte

Fail-safe values (FV) to be activated

The supported formats for safety I/O data are described in 7.1.6.4 Data Mapping for PROFIdrive on PROFIsafe.

7.1.5 Parameterization for PROFIsafe

7.1.5.1 General Information on Parameterization

When using PROFIsafe, the protocol requires specific safety parameters (F-parameters) to be sent from F-Host to F-Device. These

parameter values must be set to the Advanced safety option board with the VACON

®

Safe tool and to F-Host with its configuration

tool. During start-up, the values on F-Host are transmitted to the Advanced safety option board, which does a check of the values

against the values on the Advanced safety option board. The values configured to F-Host and F-Device must be the same for the

safety communication to start.

The safety layer starts whenever the communication channel (PROFIBUS/PROFINET) is communicating cyclically. Refer to chapter

"Commissioning" of the user guide of the used fieldbus. An unsuccessful initialization of the PROFIsafe protocol does not affect the

PROFIBUS/PROFINET cyclic communication. The PROFIBUS/PROFINET cyclic communication can be used to read diagnostic infor-

mation if the PROFIsafe parameterization fails.

See the PROFIsafe parameters in 8.3.1 PROFIsafe Parameters.

AQ319736045637en-000101 / DPD01798 | 113Danfoss A/S © 2021.06

Safe Fieldbuses

VACON® NXP Advanced Safety Options

Operating Guide

Loading...

Loading...