Chapter 2 Specifications

PAGE 2-4

2-3. Model

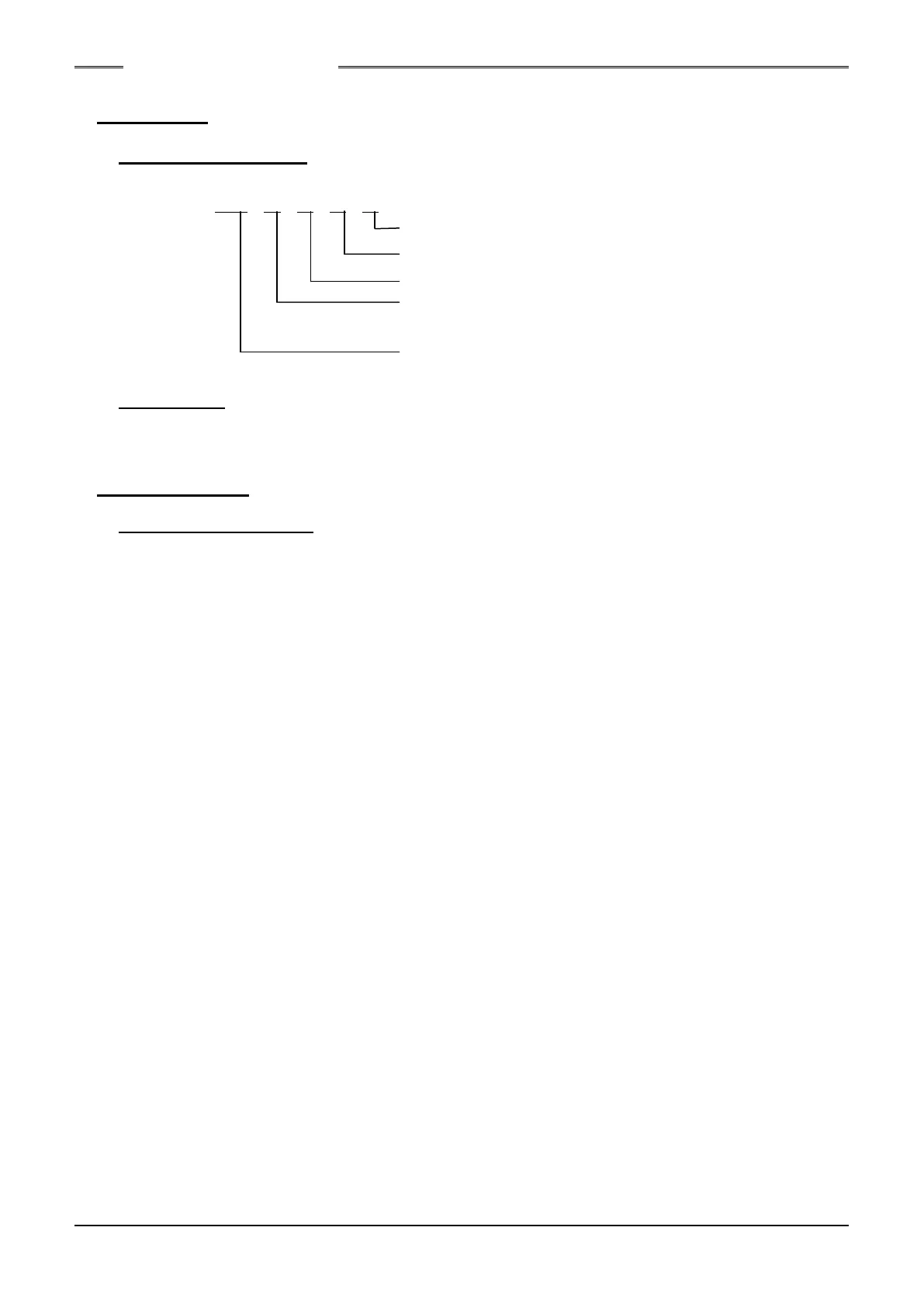

2-3-1. Controller Unit

HFC-B0**-*-*-*-*

N:Option4 nothing EN:EtherNet

N:Option3 nothing CF:CF Card(RS232C-2)

N:Option2 nothing IO:I/O terminal is attached

N:Option1 nothing CC:CC-Link DN:DeviceNet

PB:ProfiBusDPV1 PI:ProfiNetIO EI:EtherNetI/P

16:16A 24A:24A

2-3-2. Tools

Please refer to the appendix.

2-4. Functions

2-4-1. Main Functions

(1) Fastening Function

The HAND SYSTEM is capable of the following fastening methods.

1. Torque method: Angle monitor, Torque rate monitor, 1/2/3 step fastening

2. Angle method: Torque monitor, Torque rate monitor, 1/2/3 step fastening

(2) Self-Check Function

When the start lever is gripped (turned ON), the home-position voltage level and CAL voltage level

of the torque transducer are automatically checked before fastening. This function is useful for

checking the transducer for abnormality and checking the cable for breakage etc.

(3) Bypass Function

When the BYPASS signal is input, the BYPASS signal is output to notify that the Unit is in the

BYPASS mode. Starting by the START signal cannot be performed in this mode.

If the Unit enters the BYPASS mode during fastening, fastening is stopped immediately.

(4) Abnormal Signal Output Function

When a fastening failure (NG) or a system error occurs, the tool is stopped immediately and a

signal corresponding to the problem is output. Also, the fastening failure (NG) details and the

abnormal state No. are displayed on the Unit front panel.

(5) Tool Type Checking Function

The tool model set at the unit and the tool model that is presently connected are compared when

power on or tool replacement is performed. If the tool models differ, the abnormal state number [Tool

Type Error] is generated.

S0140185-H

Loading...

Loading...