Chapter 3 Part Names

PAGE 3-3

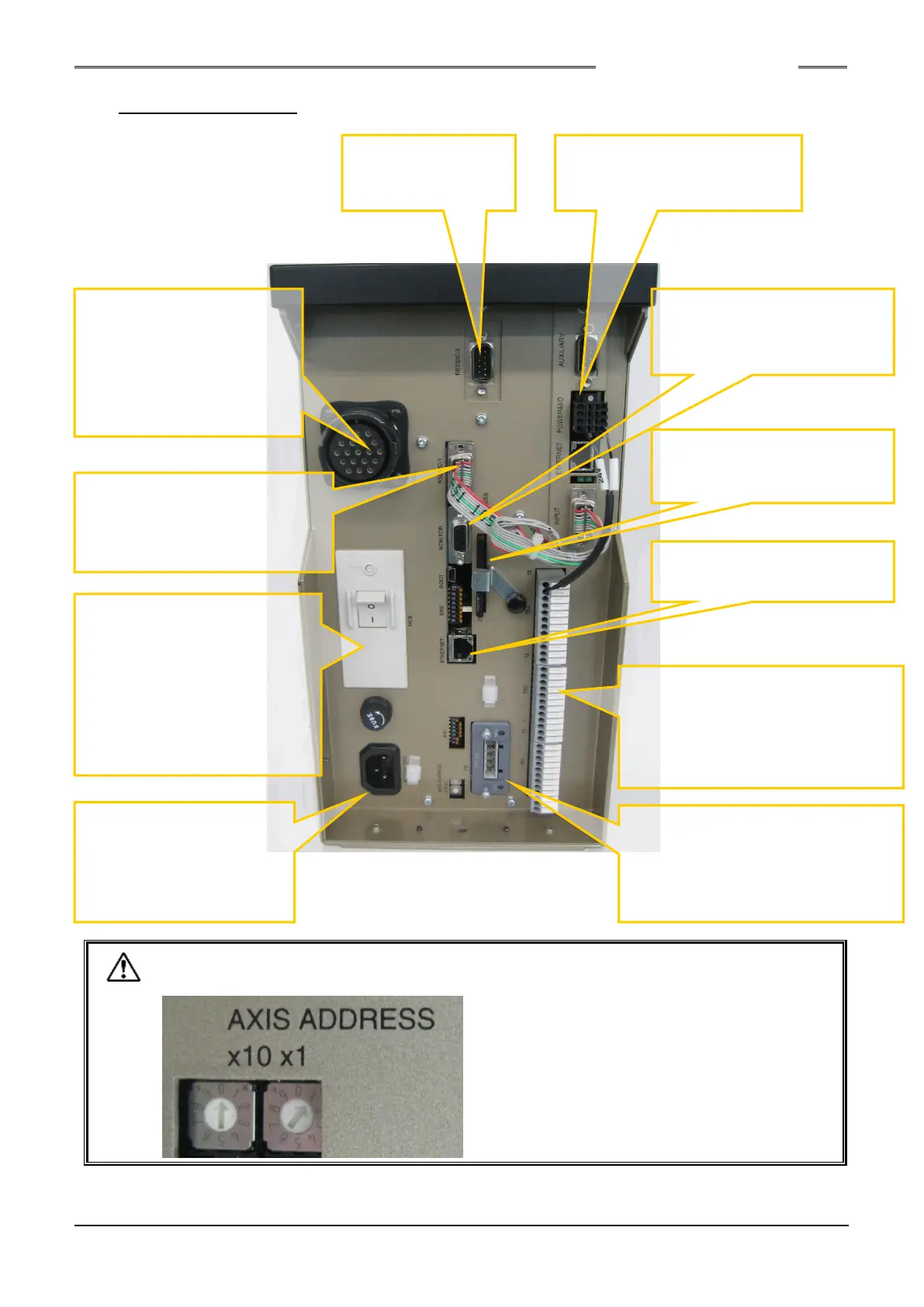

3-1-2. Bottom Panel

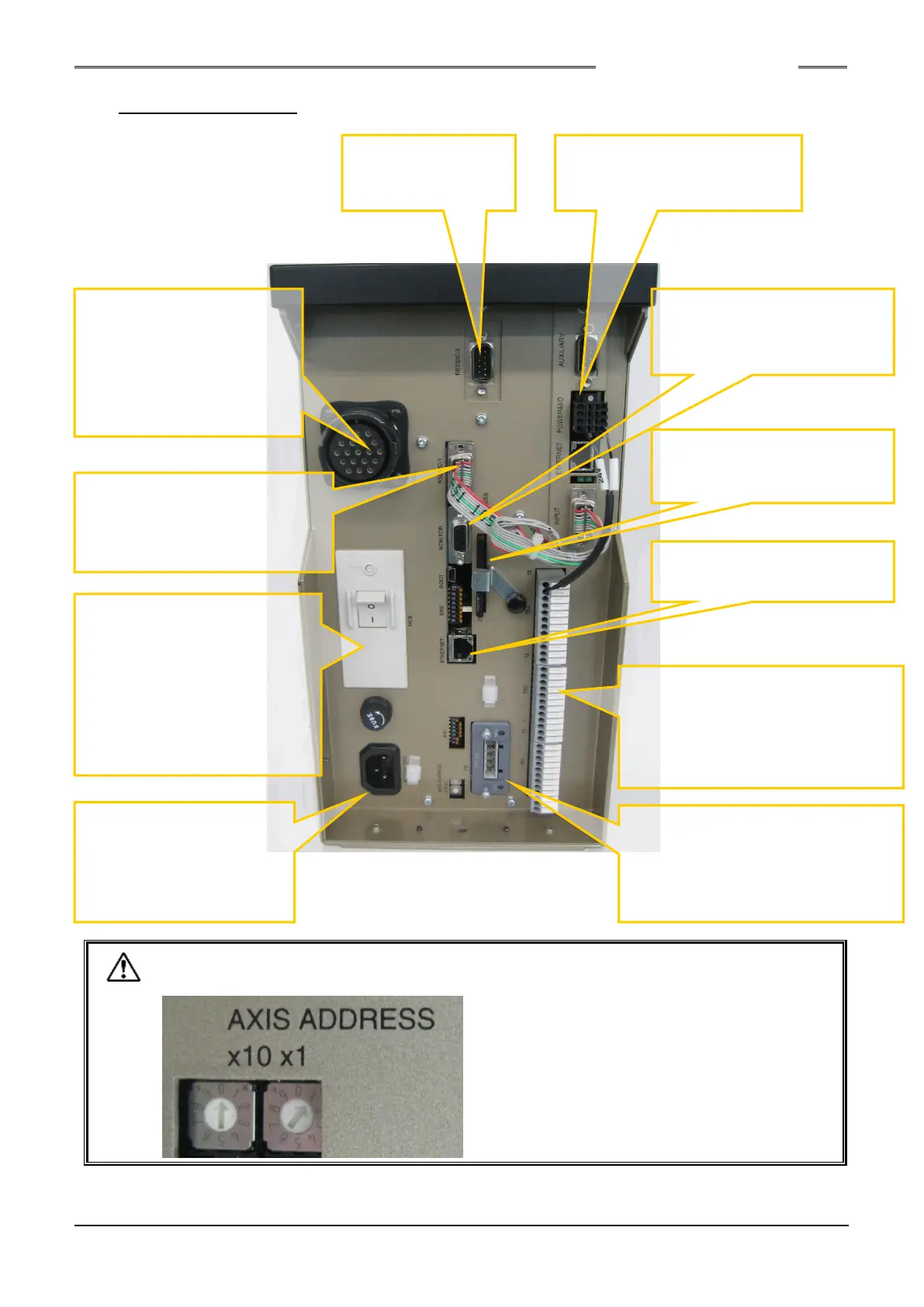

Do not change the bottom rotary switch (AXIS ADDRESS) from the setting of "× 10" to

"0" and "× 1" to "1".

T/A MON.

Connector for torque and angle

monitor output connection.

(PAGE 4-18)

RS232C-1

Connector for output of fastening

result data.

Can be connected to a PLC, printer,

PC, etc. (PAGE 4-19).

100~240V AC

Primary power source input

connector

Operates on a single-phase

50/60Hz power source.

Provide secure grounding.

TB1,2,3

Connector for input/output

connection.

Refer to separate section for signal

details and precautions (PAGE 4-6).

Electric leakage breaker

When an electric leakage

occurs in the Unit, cable, or

tool, this breaker trip

instantaneously to secure

safety from the electric

leakage.

I…ON

O…OFF

TOOL

Connector for tool cable

connection.

Twist lock type connector.

Can be connected and

disconnected by twisting by 90

degrees.

Various FIELDBUS ports(Option)

The communication specification can

be selected from among DeviceNet,

PROFIBUS, CC-Link, etc., in

accordance with the user specifications

(PAGE 9-1~).

RS232C-2(Option)

For ID data input

CF Card(Option)

Stores fastening result data

and curve data.

ETHERNET(Option)

For Data Report

ETHERNET

For PC Coummunication

S0140185-H

Loading...

Loading...