Chapter 6 Description of Operations

PAGE 6-23

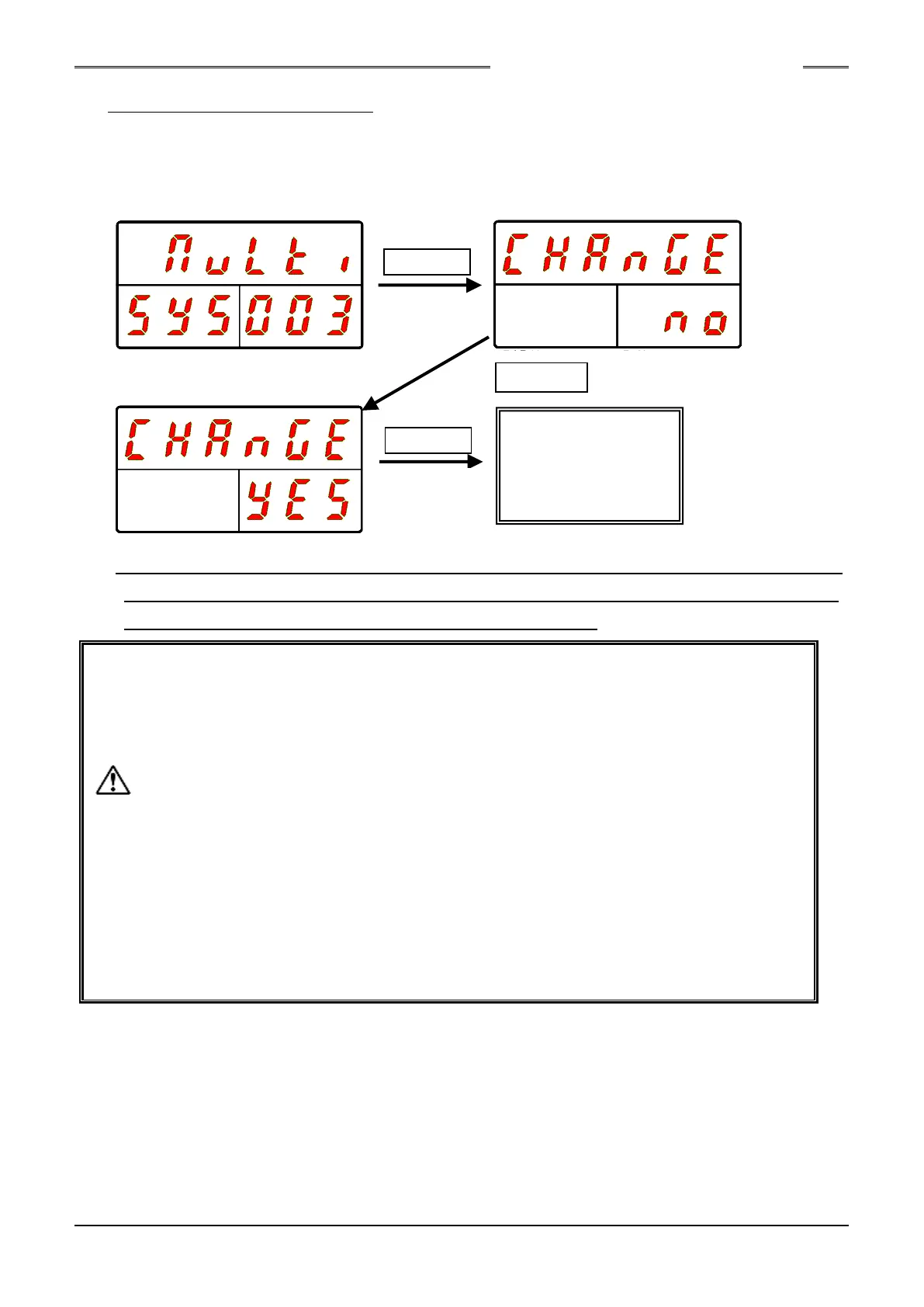

●System Parameter Setting Method

A parameter with which [SYS] is indicated in the COUNT/D-No. indication part is a system

parameter and its set value is changed by editing the set value, then pressing the [SET] switch,

thereafter changing the indication of “NO” to “YES” with the [▲] or [▼] switch, and then pressing the

[SET] switch again.

*If after pressing the [SET] switch and then changing from “NO” to “YES,” 2 seconds elapses without

operating the [▲] or [▼] switch before the [SET] switch is pressed again, changing to the set value

selection mode is performed without the set value being changed.

•When changing from the PROGRAM mode to the RUN mode is performed or the

BYPASS signal is changed from ON to OFF, the changed parameter is stored in the

Unit. When during a setting change, the power is turned OFF in the PROGRAM

mode, the setting of the parameter returns to that before the change.

•A portion of the system parameters are made available by reactivating the control

power after changing its setting (D-No. 003 System Indication, D-Nos. 011 ~ 016

TCP/IP Setting, etc.).

•When the Unit setup tool No. (PAR No. “SYS,” D-No. “200”) is changed, the fastening

parameter set values are subject to initialization and automatic correction.

•Initialization…The calibration torque, the rate 1 ~ 3 high and low limits, the full scale

current, the high current limit, and the current limit are subject to initialization.

•Automatic Correction…If the torque, speed, or low current limit set value falls outside

the high or low limit value of the tool of the tool No. for which the set value was

changed, this set value is subject to automatic correction.

Change of

System

Parameter

S0140185-H

Loading...

Loading...