Milling Quality Problems

72

Chapter 4 Troubleshooting

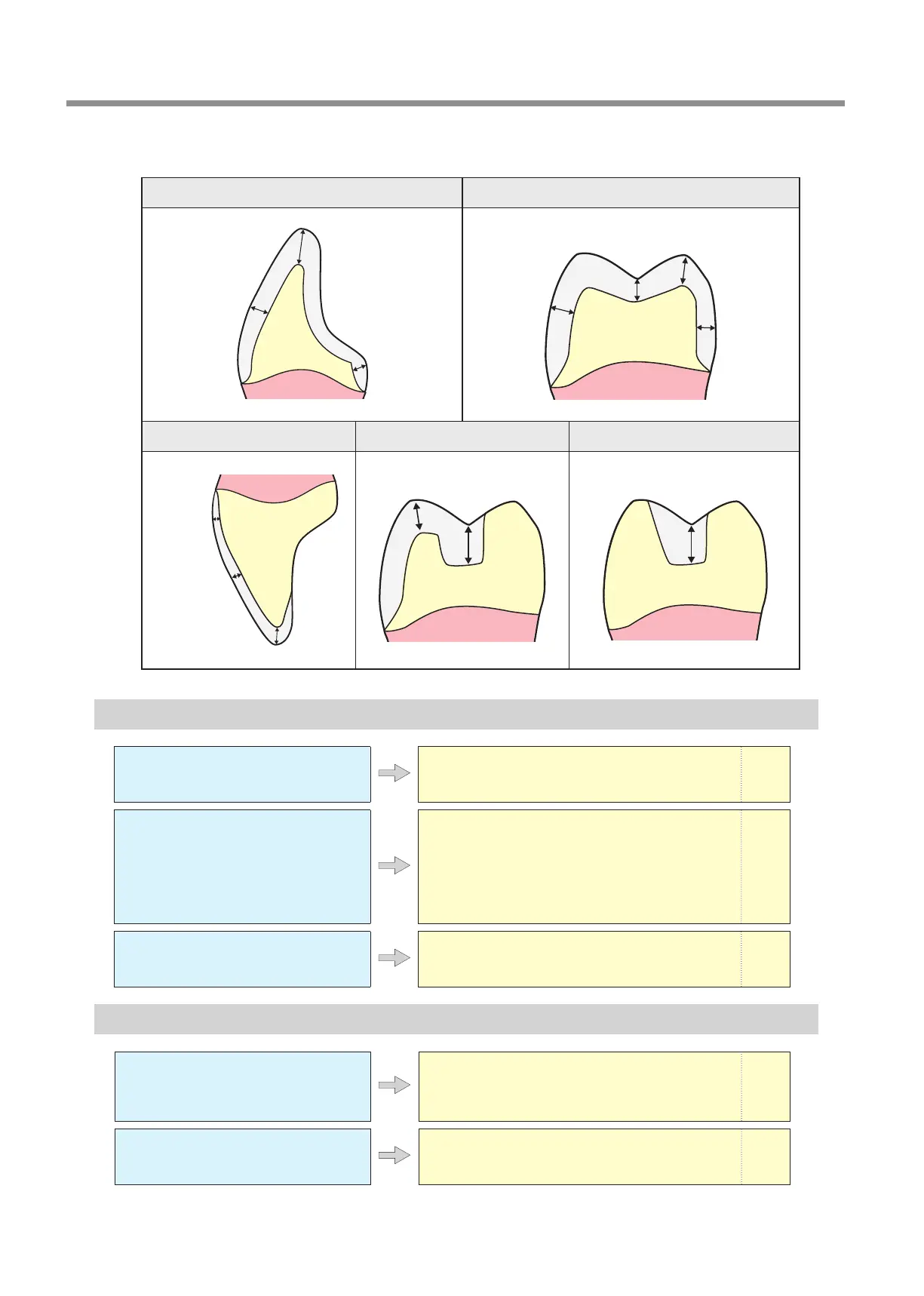

Recommended CAD data thickness values

Unit: mm

Front tooth crown Molar tooth crown

Veneer Onlay Inlay

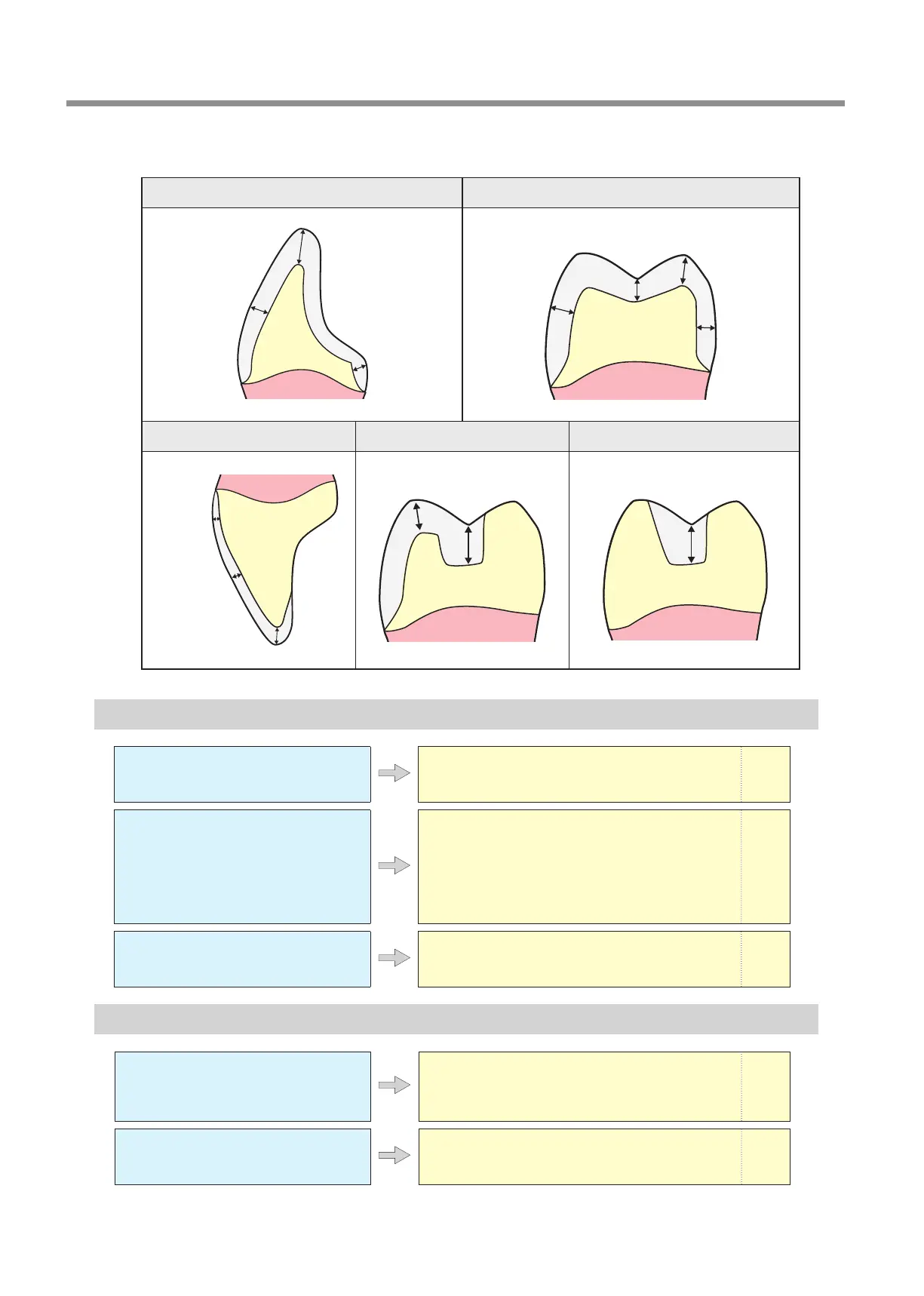

A Hole Opens in the Milling Results

Do the milling bur diameter and

stocker number match the CAM

settings?

Check the CAM's milling bur settings. —

Is the machine out of correction?

The origin point may become out of position due to pro-

longed use or relocating the machine, which can aect

milling results. Perform automatic correction. If the ex-

pected results cannot be obtained even after perform-

ing automatic correction, perform manual correction.

With manual correction, changing the Z value in the +

direction in Origin point may improve the situation.

P.53

Are the milling conditions too

strict?

Strict milling conditions may aect milling results.

Review the CAM milling conditions.

—

The Dimensions of the Milling Results Do Not Match

Does the milling bur diameter match

the CAM settings? Is the CAM

shrinkage factor setting appropriate

for the workpiece?

Check the CAM settings. —

Do the settings of the sintering

program match the workpiece?

Check the sintering program settings to see if they

match the manufacturer’s workpiece being used.

—

1.0 to 1.2

1.5 or higher

0.8 or higher

0.5 to 1.5

0.4 or

higher

0.6 or higher

1.5 or higher

1.5 or higher

1.0 or higher

1.5 or higher

0.8 or higher

1.0 or higher

1.0 or higher

Loading...

Loading...