80

Chapter 4 Troubleshooting

Responding to Error Messages

This section describes the error messages that may appear in VPanel and how to take action to remedy the problem. If the action

described here does not correct the problem or if an error message not described here appears, contact your authorized DGSHAPE

Corporation dealer.

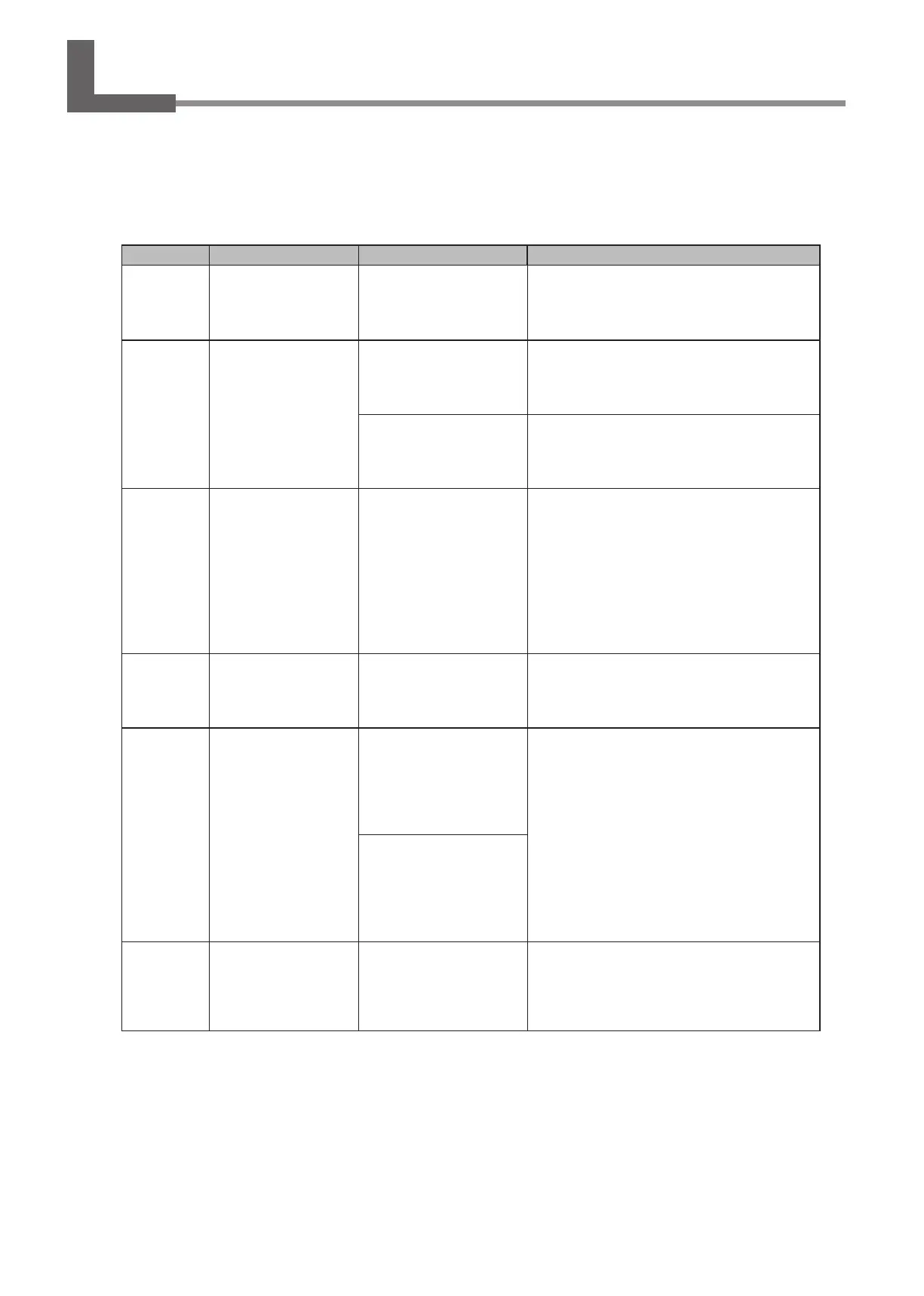

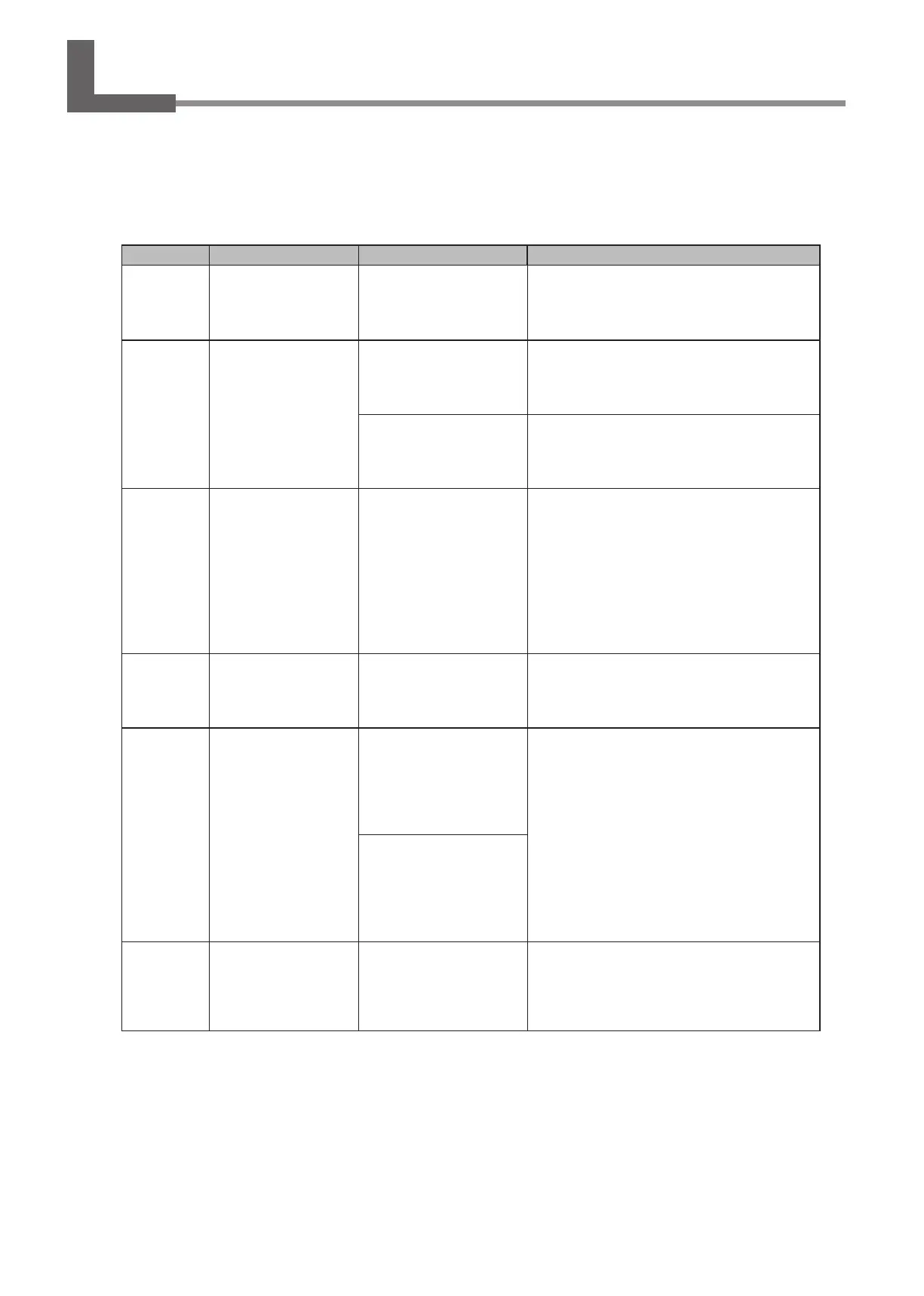

Error number Message Situation/Error Cause Action

1000‑****

The % limit switch

is not found.

(% may be "X," "Y,"

"Z," "A," or "B.")

The operation may be

inhibited by milling waste

or an obstruction.

1. Turn o the power.

2. Remove any objects blocking operation of the

machine and any accumulated milling waste.

3. Turn on the power, and then restart operation.

1006‑****

The % axis position

has been shifted.

(% may be "X," "Y,"

"Z," "A," or "B.")

The motor position may

have been lost.

1. Remove any objects blocking operation of the

machine and any accumulated milling waste.

2. Press and hold the operation button on the built-

in panel. This will clear the error.

The milling conditions may

be excessively strict.

1. Press and hold the operation button on the built-

in panel. This will clear the error.

2. Review the CAM settings and the shape specied

in the CAD data.

1017‑0000

The front cover was

opened.

The front cover was opened

during spindle rotation.

(For safety, the machine

comes to an emergency

stop if the front cover is

opened while the spindle is

rotating.)

To continue milling

Press the operation button on the built-in panel to

resume milling.

To abort milling

Press and hold the built-in panel's operation

button.

Do not open the front cover while the spindle is

rotating. Doing so may aect the milling results.

101C‑0000

The milling bur

sensor was not

found.

The operation may be

inhibited by milling waste

or an obstruction.

1. Turn o the power.

2. Remove any objects blocking operation of the

machine and any accumulated milling waste.

3. Turn on the power, and then restart operation.

101D‑****

The % milling bur

cannot be released.

(% may be "1" to

"15.")

The returning of the milling

bur failed. The inside of the

collet or the ATC magazine

might be dirty.

1. Press and hold the operation button on the built-

in panel. This will clear the error.

2. Clicking "Open collet" in VPanel will open the

collet. Remove the milling bur.

"

P. 11 ""Maintenance" Tab"

3. Clean the ATC magazine.

"

P. 48 "Cleaning after Milling Finishes"

4. Retighten the collet.

"

P. 59 "Retightening the Collet"

If the error occurs again even after you perform the

above operations, the collet may be deformed. In

this case, replace the collet.

The collet and milling bur

are axed together and

cannot be separated. The

inside of the collet might

be dirty.

101D‑0010

The cleaning tool

cannot be released.

The operation to return the

cleaning tool failed. The

inside of the collet or the

ATC magazine might be

dirty.

1. Press and hold the operation button on the built-

in panel.

2. Perform "Open collet" in VPanel.

3. Remove the cleaning tool.

4. Clean the ATC magazine.

Loading...

Loading...