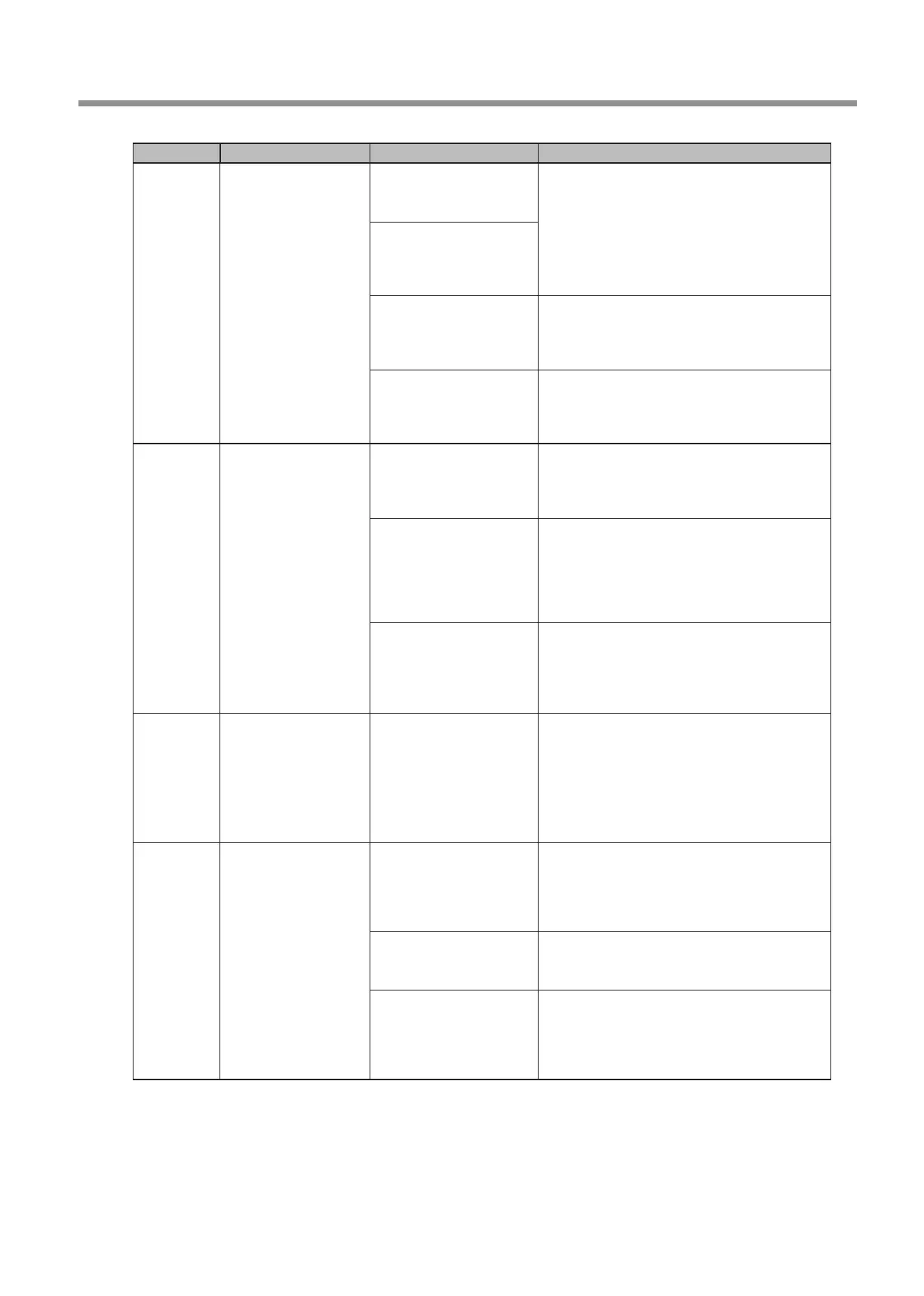

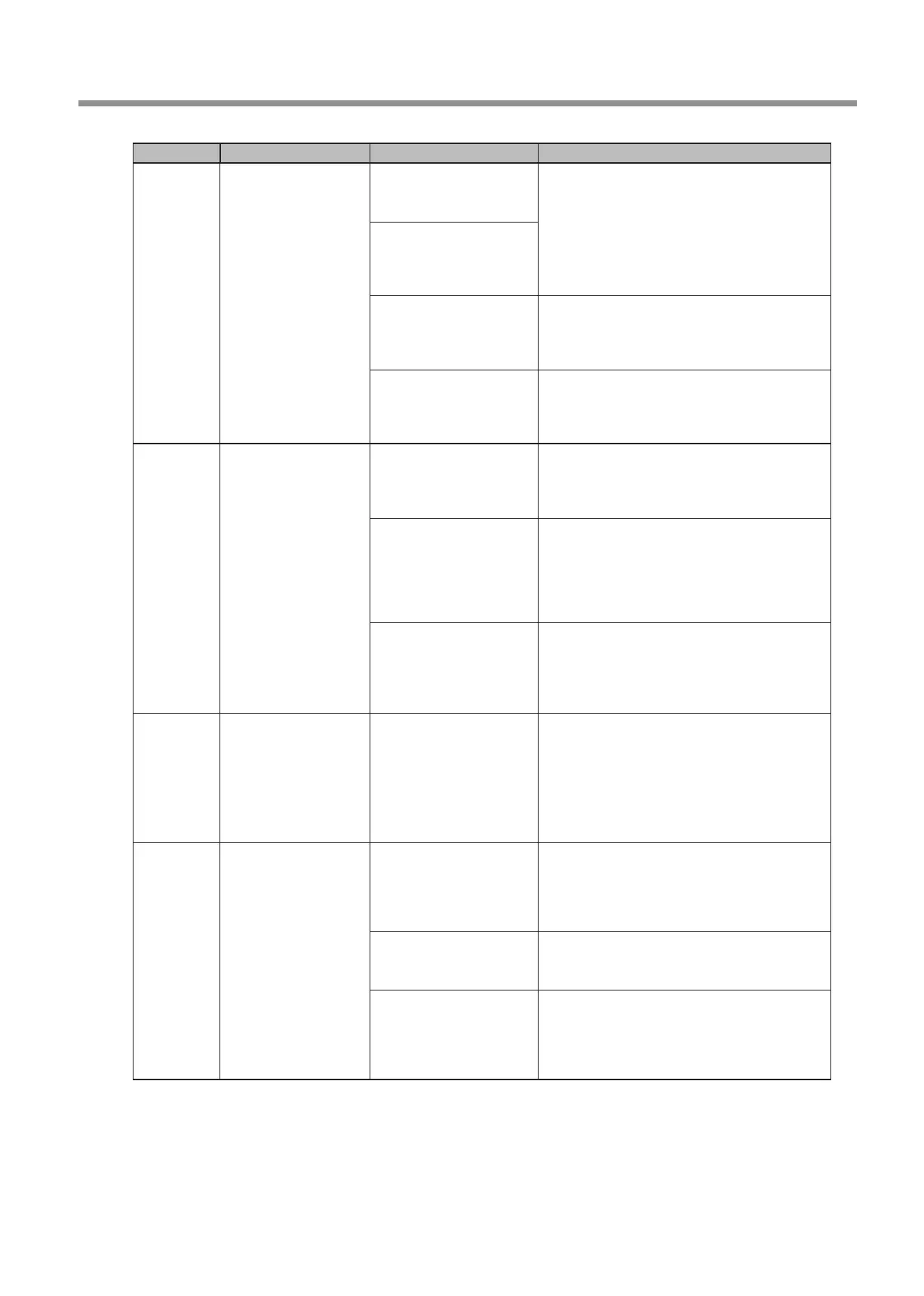

Responding to Error Messages

81

Chapter 4 Troubleshooting

Error number Message Situation/Error Cause Action

101E‑****

The % milling bur

might be broken.

(% may be "1" to

"15.")

The milling bur might be

broken.

1. Press and hold the operation button on the built-

in panel to clear the error.

2. If the milling bur is broken, replace it with a new

one.

3. If the position of the milling bur holder is not

appropriate, correct the position.

"

P. 36 "STEP 3: Loading the Milling Bur"

The milling bur holder

might be out of position.

The milling conditions may

be excessively strict.

1. Press and hold the operation button on the built-

in panel. This will clear the error.

2. Review the CAM settings and the shape specied

in the CAD data.

The collet may have worn

out.

If the error occurs again even after you perform the

above operations, the collet may have worn out,

leading to a decrease in its retention capabilities.

Replace the collet with a new one.

101F‑****

The % milling

bur chucking has

slipped out.

(% may be "1" to

"15.")

The collet may have come

loose.

1. Press and hold the operation button on the built-

in panel to clear the error.

2. Retighten the collet.

"

P. 59 "Retightening the Collet"

The milling conditions may

be excessively strict.

1. Press and hold the operation button on the built-

in panel.

This will clear the error.

2. Review the CAM settings and the shape specied

in the CAD data.

The collet may have worn

out.

If the error occurs again even after you perform the

above operations, the collet may have worn out,

leading to a decrease in its retention capabilities.

Replace the collet with a new one.

1020‑****

1021‑****

The % milling bur is

too long.

The % milling bur is

too short.

(% may be "1" to

"15.")

There is a possibility that

the position of the milling

bur holder is not correct.

Replace the milling bur with one of the appropriate

length (40 to 55 mm). Also check the position of the

milling bur holder.

"

P. 36 "STEP 3: Loading the Milling Bur"

1022‑****

The % milling bur

was not found.

(% may be "1" to

"15.")

The milling bur has not

been set or it may have

been mounted on an

incorrect stocker number.

1. Set the milling bur in the correct position.

If the error occurred during milling

Close the front cover, and press the built-in panel's

operation button. Milling will resume.

There is a possibility that

the ATC magazine is out of

position.

Perform automatic correction.

"

P. 53 "Correcting the Milling Machine"

The collet may have worn

out.

Replace the collet.

If the error occurs again even after you perform the

above operations, replace the spindle unit with a

new one.

Loading...

Loading...