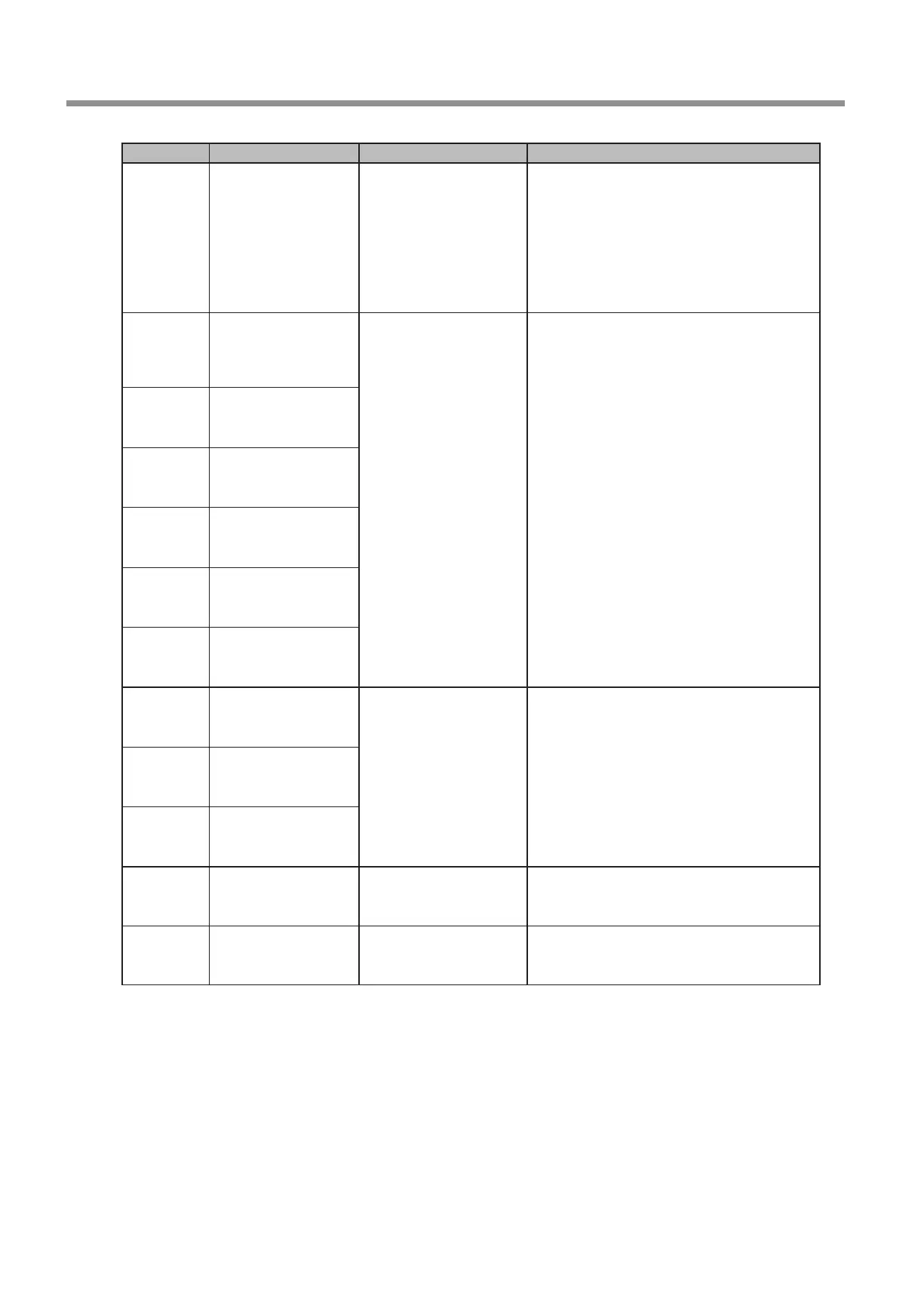

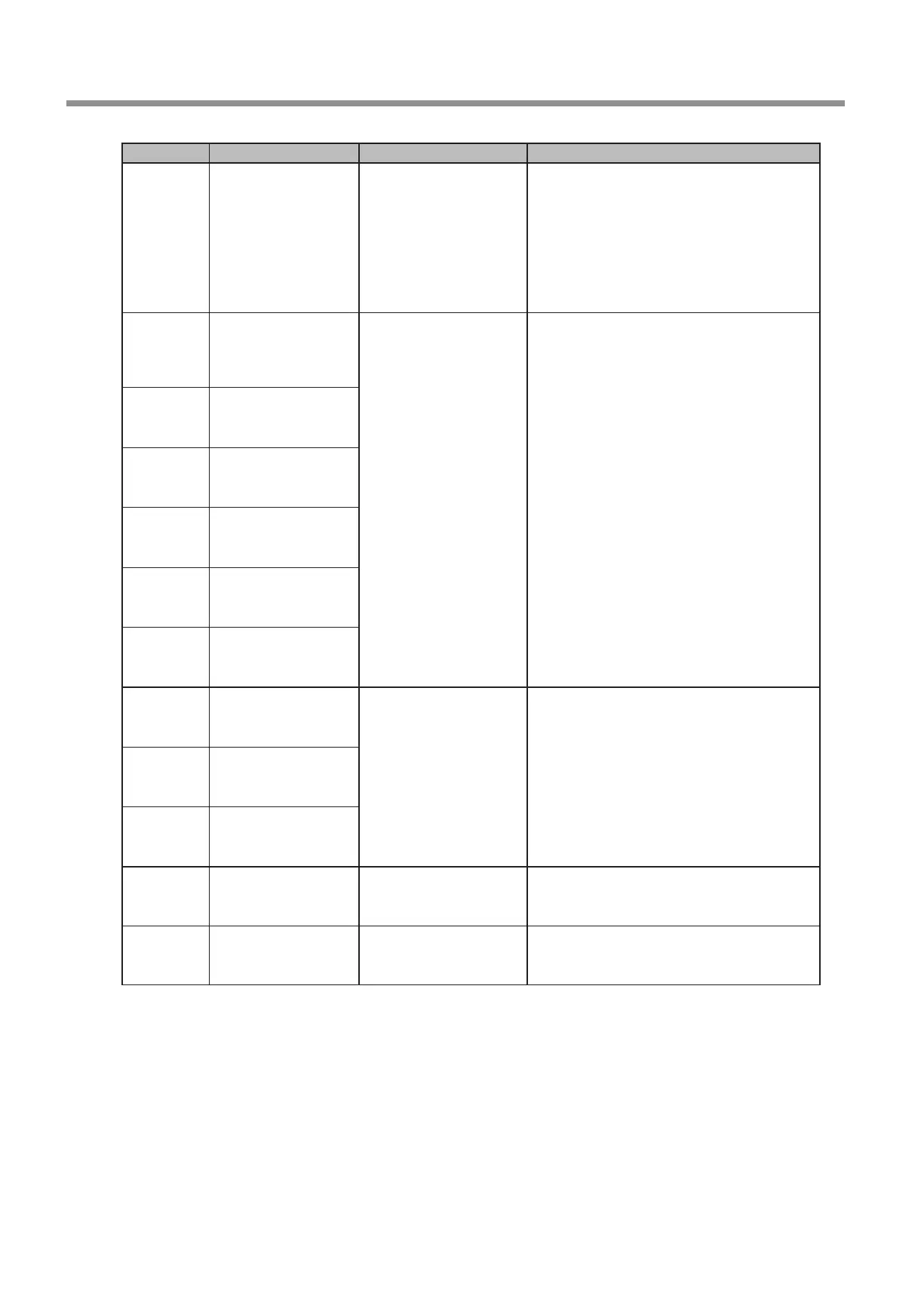

Responding to Error Messages

82

Chapter 4 Troubleshooting

Error number Message Situation/Error Cause Action

1022‑0010

The cleaning tool

was not found.

The cleaning tool has not

been set or it may have

been set on an incorrect

stocker number.

Set the cleaning tool in the correct position.

If the error occurred during milling

Press the operation button on the built-in panel.

If the error occurred while the machine

was on standby

Press and hold the operation button on the built-in

panel.

1023‑0000

Milling data error.

The number of

parameters is

incorrect.

There may be a problem

with the milling data

received from the computer.

<When using Intelligent

Tool Control>

When using CAM to select

the stocker number, the

stocker number set as the

second or third milling bur

in Intelligent Tool Control

has been selected.

1. Press and hold the operation button on the built-

in panel. This will clear the error.

2. Check the milling data.

If there are no problems with the milling data,

restart the computer, and then perform milling

again.

<When using Intelligent Tool Control>

When using CAM to select the stocker number, do

not select the stocker number set as the second or

third milling bur in Intelligent Tool Control.

"

P. 45 "Automatically Switching Out the Worn Milling

Bur (Intelligent Tool Control)"

1024‑0000

Milling data error.

The parameter is

out of range.

1025-0000

Milling data error. A

wrong command is

detected.

1026‑0000

Milling data error.

The address is not

dened.

1027‑0000

Milling data error.

The parameter is

not dened.

1028‑0000

Milling data error.

The operation

cannot be executed.

1029‑0000

The spindle

experienced an

overload.

The spindle stopped under

a large cutting load or

due to a similar cause. The

following are likely reasons.

• The milling bur is worn.

• A workpiece that cannot

be cut by the machine is

being used.

• The cutting conditions are

too strict.

1. Turn o the power.

2. Check the milling bur, the workpiece, and the

CAM settings as well as the shape specied in the

milling data.

3. Allow the machine to rest for some time before

turning the power on because the motor may have

overheated.

102A‑0000

The spindle

experienced

overcurrent.

102B‑0000

The spindle motor

temperature is too

high.

102D‑0000

The spindle can not

be turned.

The cable may be broken

or the spindle unit may be

defective.

Turn o the power and contact your authorized

DGSHAPE Corporation dealer.

1030‑0000

The dust collector is

not working.

Make sure the dust collector

is connected correctly and

the power is on.

Turn the dust collector on, and then check the dust

collector settings and the lter.

Loading...

Loading...