148

ADJUSTMENTS - MAINTENANCE

1

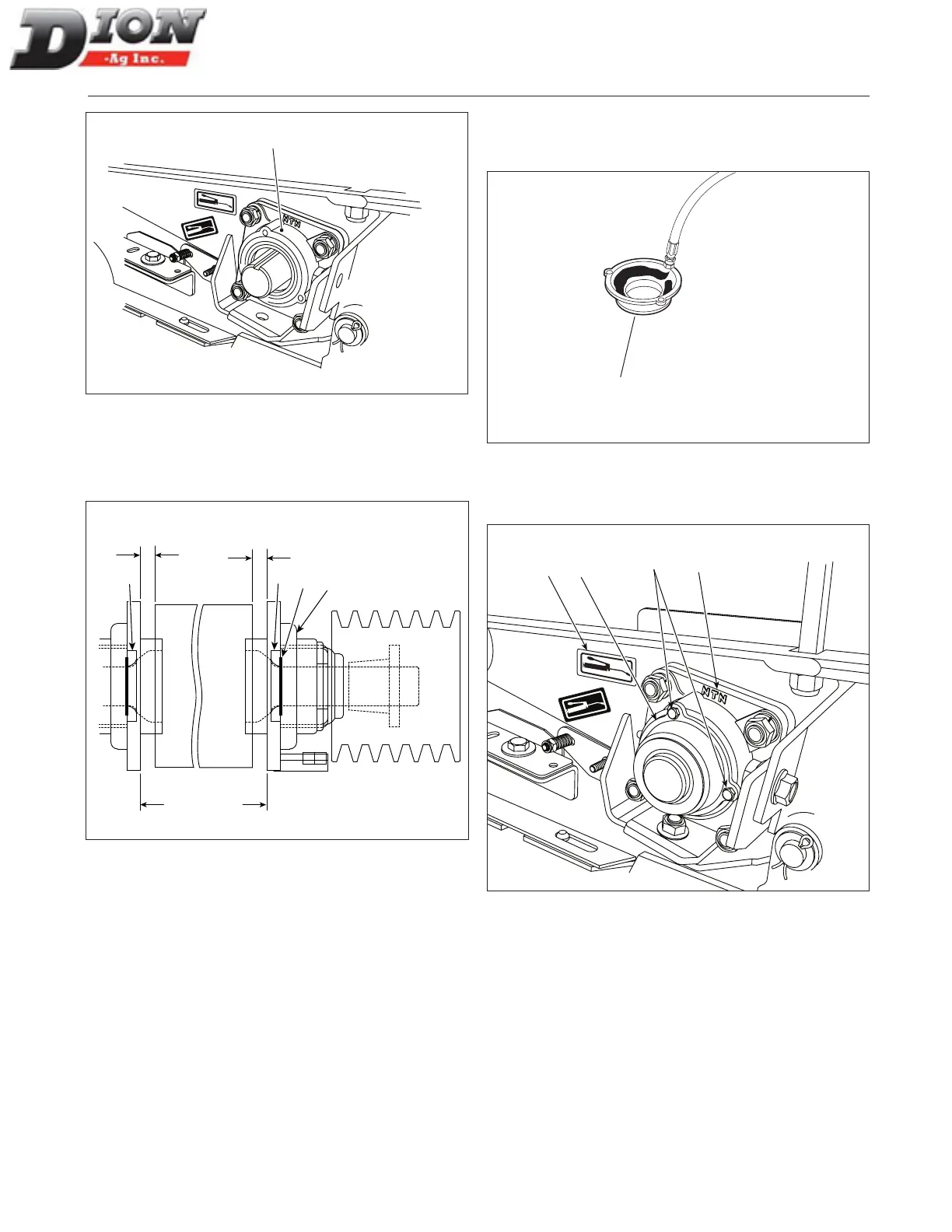

Figure 226

5. When replacing the upper roll, use 1/16” spacers

(item 10) in order to obtain the proper dimension

(Figure 227).

10

11

7

7

9/16” ± 1/16”

9/16” ± 1/16”

24 15/16”

24 13/16”

Figure 227

NOTE: When sliding the bearing on the shaft, make

sure the grease tting (item 10) is correctly ori-

ented so it can be easily connected.

NOTE: Apply “Loctite 262” to the set screws. Tighten

set screws to 45 in-lbs (5 N-m).

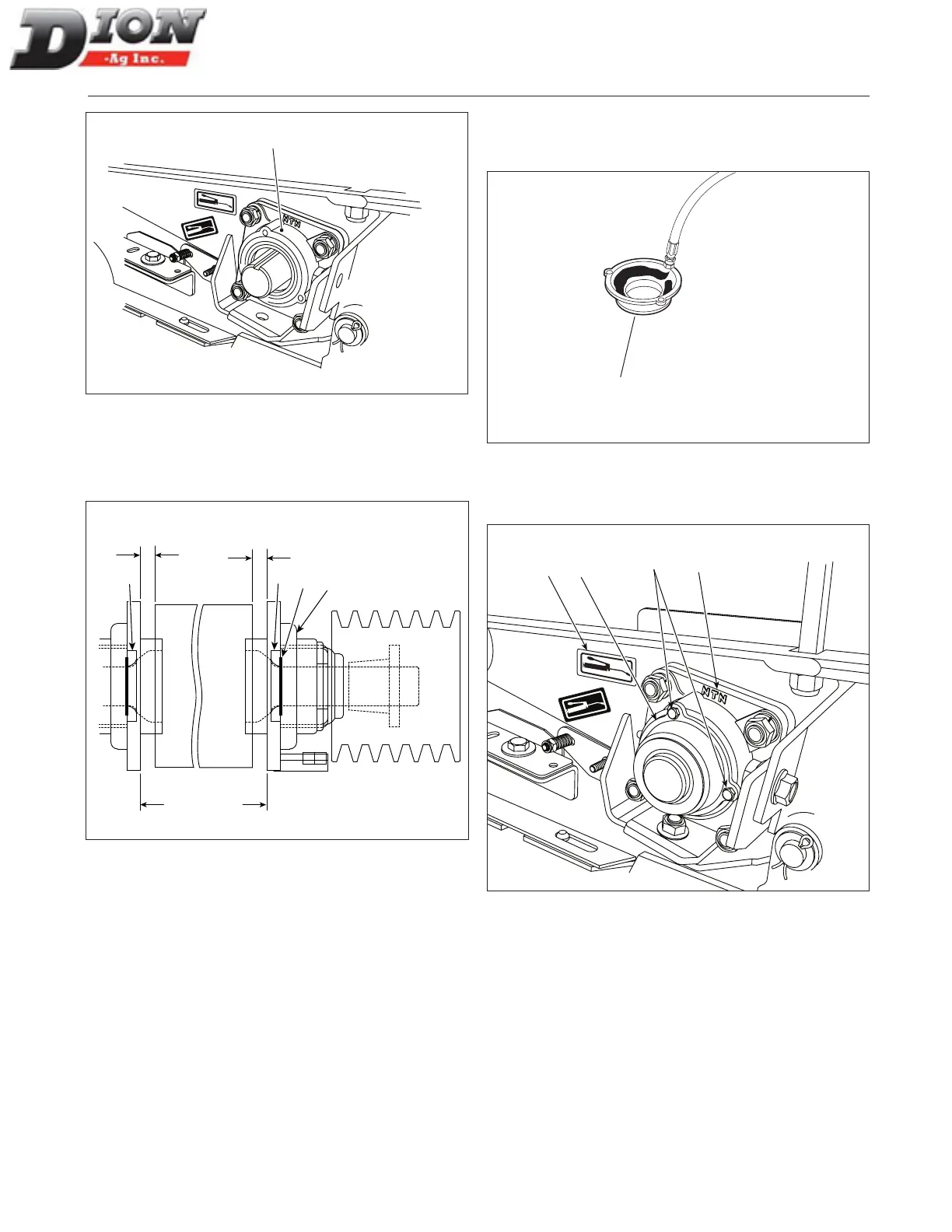

6. Fill the grease cap (item 2) carefully with grease

along with the cap seal ring contour. Leave a hole

according to the shaft diameter.

2

Figure 228

7. Bolt grease cap (item 2) with three bolts (item 3 - sup-

plied) and tighten securely.

1

3

2

10

Figure 229

8. Lubricate the grease tting (item 10) until grease

starts to exit from the hole under the support brack-

et (item 4).

NOTE: This will protect the bearing seal against contam-

ination from silage.

Manual No. F4117E987E V1.1

Loading...

Loading...