149

ADJUSTMENTS - MAINTENANCE

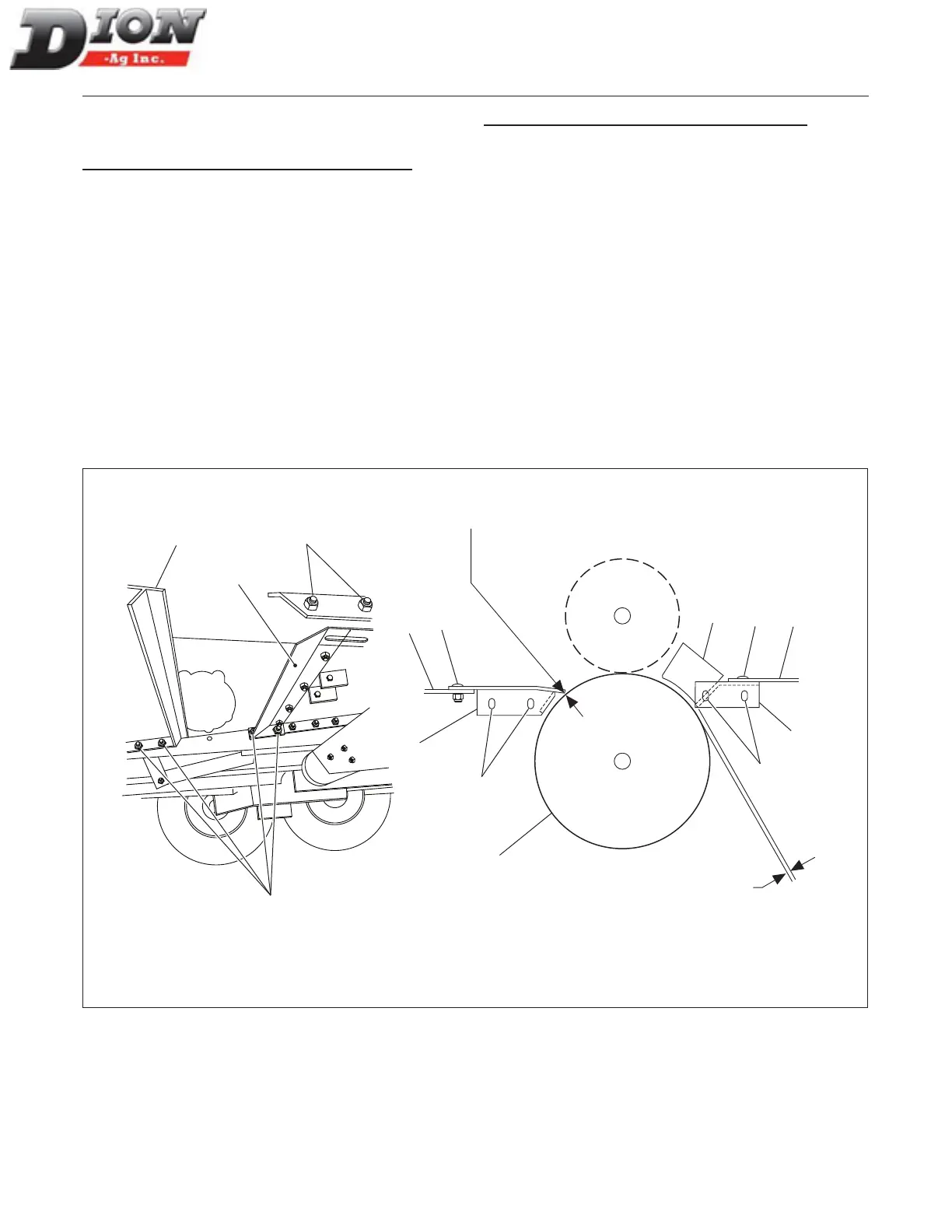

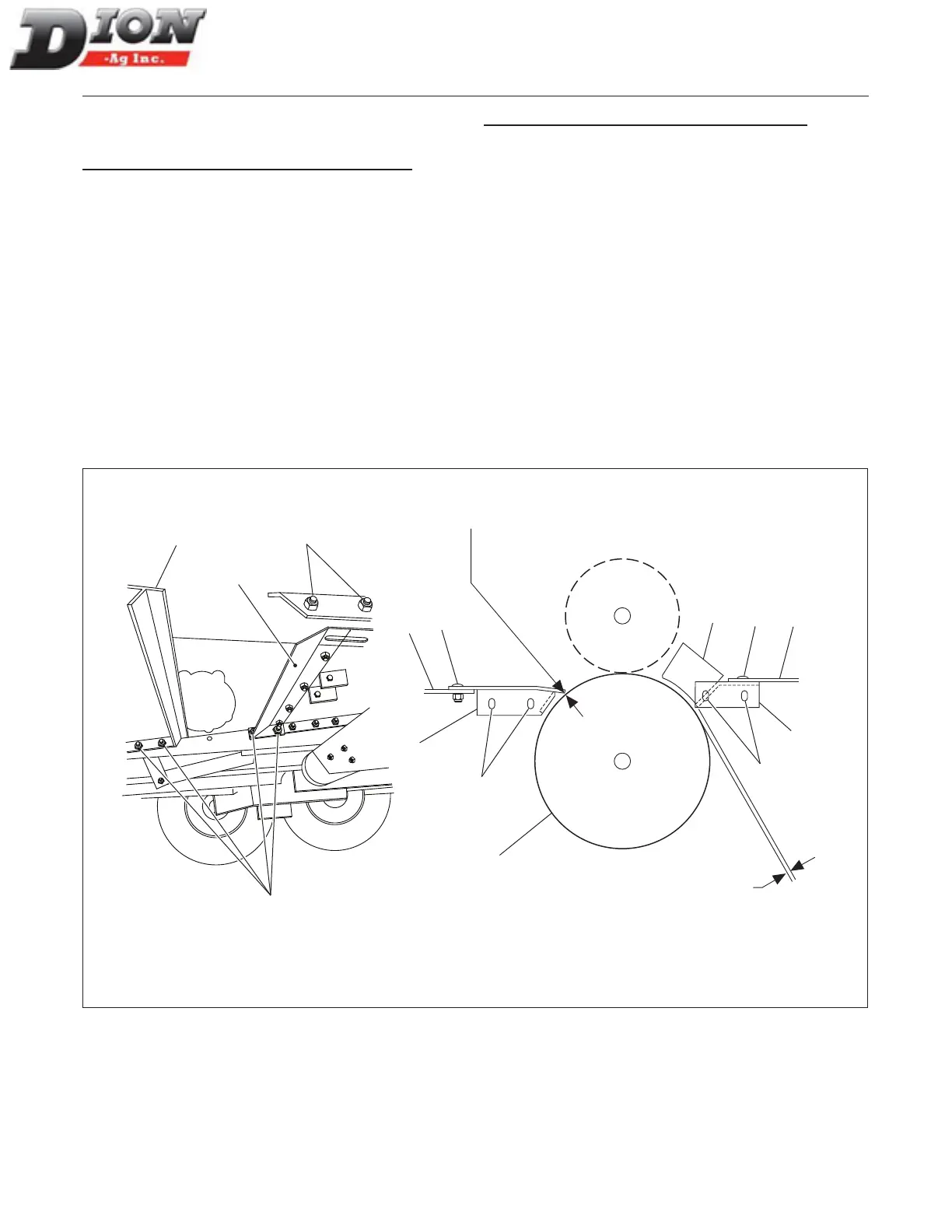

CORN CRACKER LOWER ROLL HALF BOTTOM

PLATE - FIGURE 230 TO FIGURE 233

To adjust the front half bottom plate (item 1):

Loosen all bolts and leave a lengthwise clearance of

1/16” to 1/8” (1.5 to 3) between the front half bottom

plate and the lower roll (item 3).

NOTE: The front half bottom plate must always be bolt-

ed under the Cutter Head bottom plate (item 4).

Tighten all bolts securely.

NOTE: Check deector wear (item 7) and replace them

if necessary. Worn deectors will let corn leak

between the end of the cracker roll and the ma-

chine frame.

NOTE: A tall reector is used on the left-hand side and

a short one on the right-hand side (item 7).

To adjust the rear half bottom plate (item 2):

After installing the rear bottom plate and the adjustment

bolt support bracket, it will be necessary to adjust the

distance between lower roll and the rear half bottom.

NOTE: The front half bottom plate (item 2) must always

be bolted over the fan bottom plate (item 5).

Tighten all bolts securely.

NOTE: The lower Corn Cracker roll must NOT touch

the rear half bottom plate. Use gauges with

recoended thickness, as shown here.

2

1

6

6

6

6

7

4

5

1

2

6

1/32” (0.8 mm)

1/16” to 1/8” (1.5 to 3 mm)

6

3

REAR FRONT

Figure 230 Half bottom plates on the lower corn cracker roll

Manual No. F4117E987E V1.1

Loading...

Loading...