Checking

the Generator for Proper

Operation

The proper operation

of

the

generator

should be checked

on

a spe-

cial benc

h:

in the motor dutv;

during

idling; -

under load.

In a

ll

checks, where application

of

vo

ltage is required, strictly

observe the polarity of

co

nnectio

n,

i.

e.

connect o

nl

y a

plu~

wire to

terminal "H".

Checking·

the

Generator

in the Motor

Duty

Th

e generator should

be

checked for mechanical

and

electrical

faults in the following order:

tLt;-n

the armature by hand

to

ch

ec

k it

fo

r free rotation;

remove the protective band, secure

the

generator

in

a holding

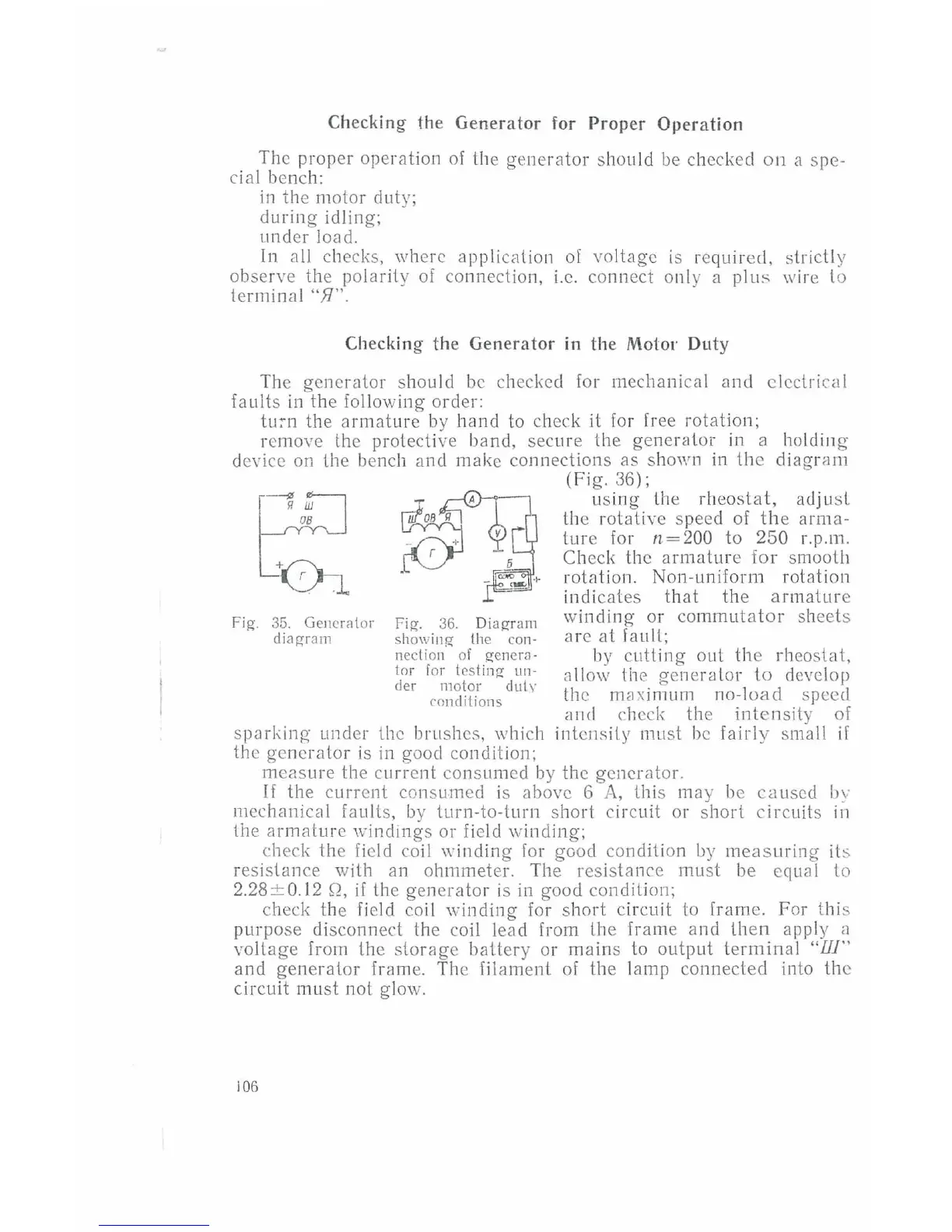

device on the bench and make connections as shown in

the

diagram

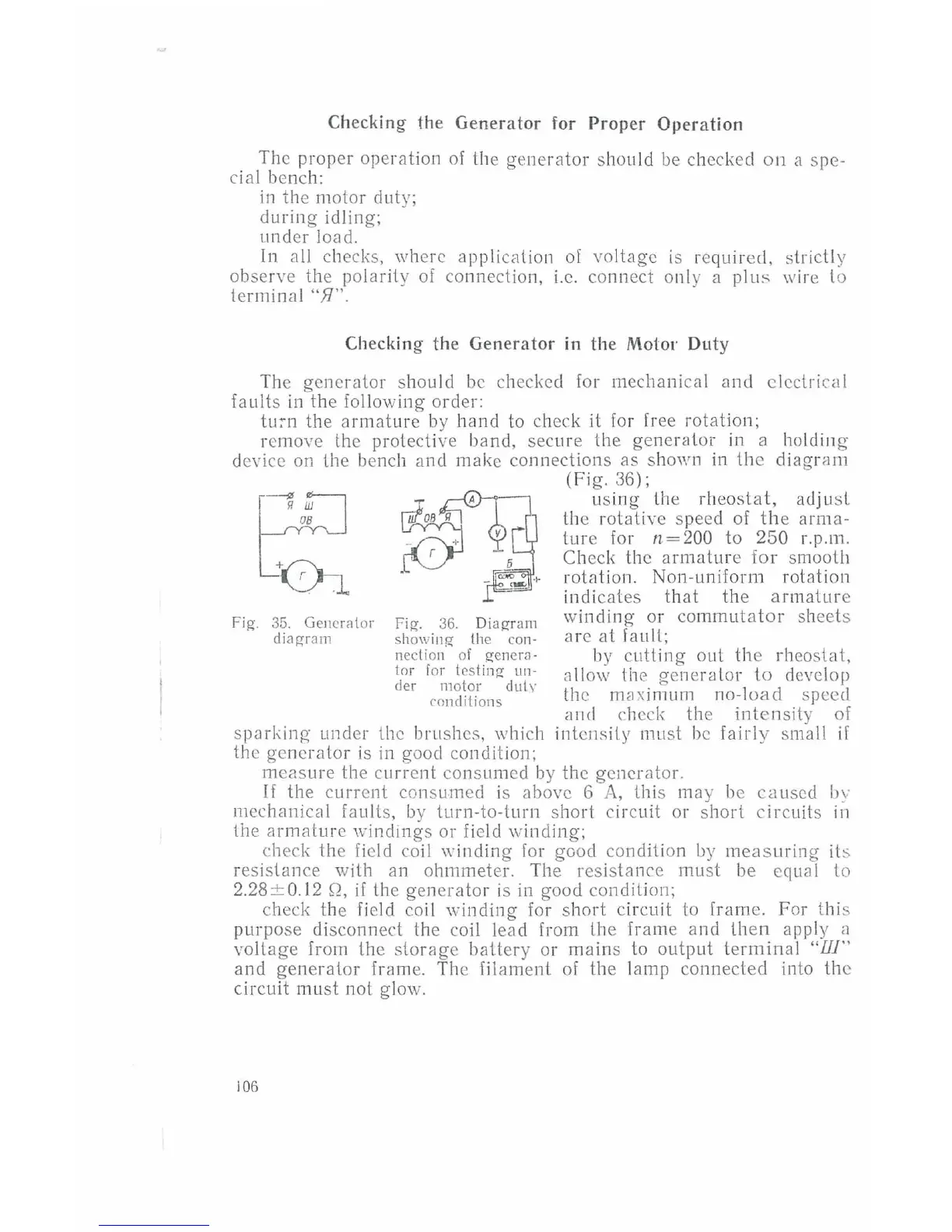

Fig. 35. Gen

era

lor

diagram

Fig. 36.

Diagr

am

sh

owing

lhe

con-

nection of

genern

·

tor

for

testing

un-

der

motor

duly

conditions

spnrking

under the brushes, which

the

generator

is

in good condition;

(Fig. 36);

usi

ng

the

rheostat,

adjust

th

e rotative speed

of

the

arma-

ture ior

n=200

to 250 r.p.m.

Check the

armature

for smooth

rotation. Non-uniform rotation

indicates

that

the

armature

winding

or

commutator

sheets

arc

at

fault;

by

cutting

out

th

e rheo

stat,

a

ll

ow

lhe generator

to

develop

the

mw-;imum no-lo

ad

speed

atiCl

check the

intensity

of

intensity mu

st

be

fairly

small

if

measure the

cu

rrent consumed

by

the generator.

If

the

current

consumed is above 6

A,

this may be

caused

bv

mechanical faults,

by

turn-to-turn short circuit or

short

circu

it

s

ii1

the arm

ature

windings or field winding;

check the field coil

\\·inding

for

good condition

by

measuring

its

resistance with an ohmmeter.

Th

e resistance must be equal to

2.28 ± 0.12

Q,

if

the

generator

is in good condition;

check the field coil

winding

for

short

circuit

to

frame. For this

purpose

di

sconnect the

co

il lead from the frame and

then

apply a

voltage from the stor

age

battery or mains to output

termin

al

"Ill"

and

generator

frame.

Th

e filament

of

the lamp connected into the

circuit must not glow.

106

Loading...

Loading...