..

9

. ..

2.

REPAIRING

THE

1\'

,A

IN

DRIVE

UNITS

AND

COMPON[NT

PARTS

When

repairing

the mnin dri\'e units

and

component p

arls,

proper

attention should

be

given io ensu.re the correct

clc;mwces

and

in

le

r-

ferewes

hchrecn !he

mating

parts· in accordance with

the

data

li

st-

ed

in

Table 9.

In

order to

rl

elermi11e ,,·hclher son:e

of

the paris

are

good

for

further usage\ refer I

·J

T.:1ble

10

listing the maximum

permissib

le

values

of

-,,

·

ear

and

dcar

:

mces

in the basic

mating

members

.

Repairing

the

Propeller

Shaft

and

Universal

Jo:nt

Th

r propeller

shaft

and universal joint are subject io repairs in

c1se

any faults are cletect.ed during their

oreralion

(the propcl

tc·r

sh:dt

lJ'.

'nt, un

iy

ersa l joint

paris

or elastic cottpling worn) .

I

nspcct a

ll

the component

pa

rts

and

especially the m2tin5;

su

r-

facr".

cb

c

.-1\

the f

r;

l

lmring

pa r

ts

ior guod

co

nditio

n:

coupling

of

lhc fle'.ible universal joint;

splines

of

the propeller

shaft

;

needle b

eo

rings

of

lhc

un

iret·s8l joint cross;

ttni\'er"al joint fo

rk

s.

Hepl<~ce

lhc defeclive parts.

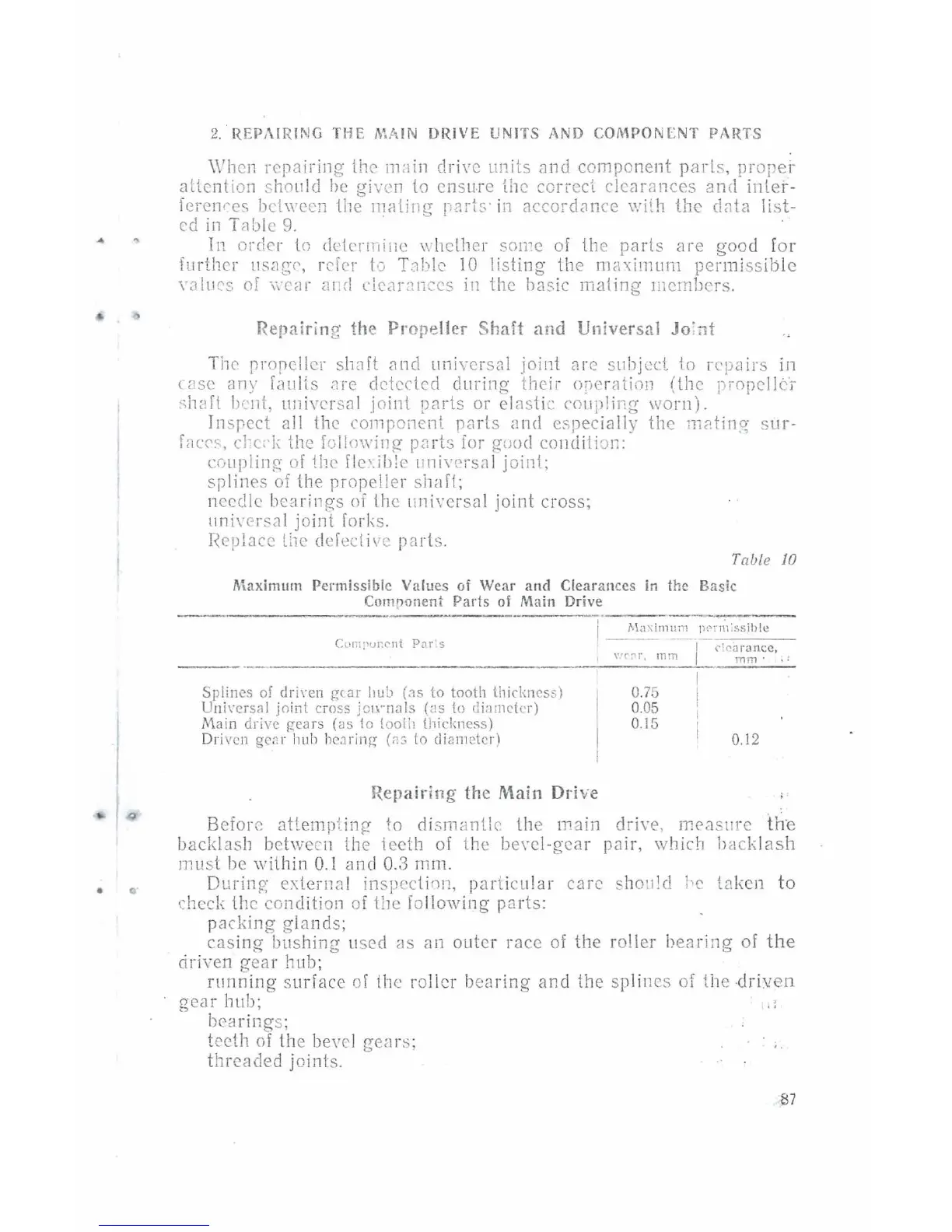

Tabl

e 10

Maximum

Permiss

ible

Values

of

Wear

and

Clear

ances

in

the

Basic

Comoonent

Parts

of

Main

Drive

---------,

S

plines

of dri1·en

gear

liub

(~s

to

tooth

thicknes

s)

Uni1·ers~l

joint

c;

oss

jownals

(

as

!o

diamc!

er)

Mai n

drive

gea

rs

(as

to loolil

thickness)

Driven ge2 r huh heJ

ring

(n 3

!o

diam

eter)

Rep

air

ing

th

e

Main

Drive

0.75

0.05

0.15

0.12

Before attempting- to

di

smanUc lhe ma

in

driw

,

measure

th

·e

backlash between the ieeth of lhe be\'Cl -gear p8ir, which backl

as

h

must

be

within

0.1

<Jn

d 0.3

rnm

.

Durin?;

e:-.:lc

;·n

nl inspection,

par

tic

ular

care sho•t!d

h•

taken

to

check the cond

iti

on

oi the

fo

llowing

p<~rts:

pa

ck

ing glands;

casing

bushing used

8S

an outer race

of

the roller bea

ri

ng

of

the

driven

gear

hub;

running

surface of ihc roller bea ring

and

the sp

li

nes

of

the dri

ven

gear

hub; ..

bearing

s;

teeth

of

the bevel gea rs; '·

threaded joints.

Loading...

Loading...