Why is my DÖRR Electronic Cigarettes atomizer not working correctly?

- MMark HowardAug 4, 2025

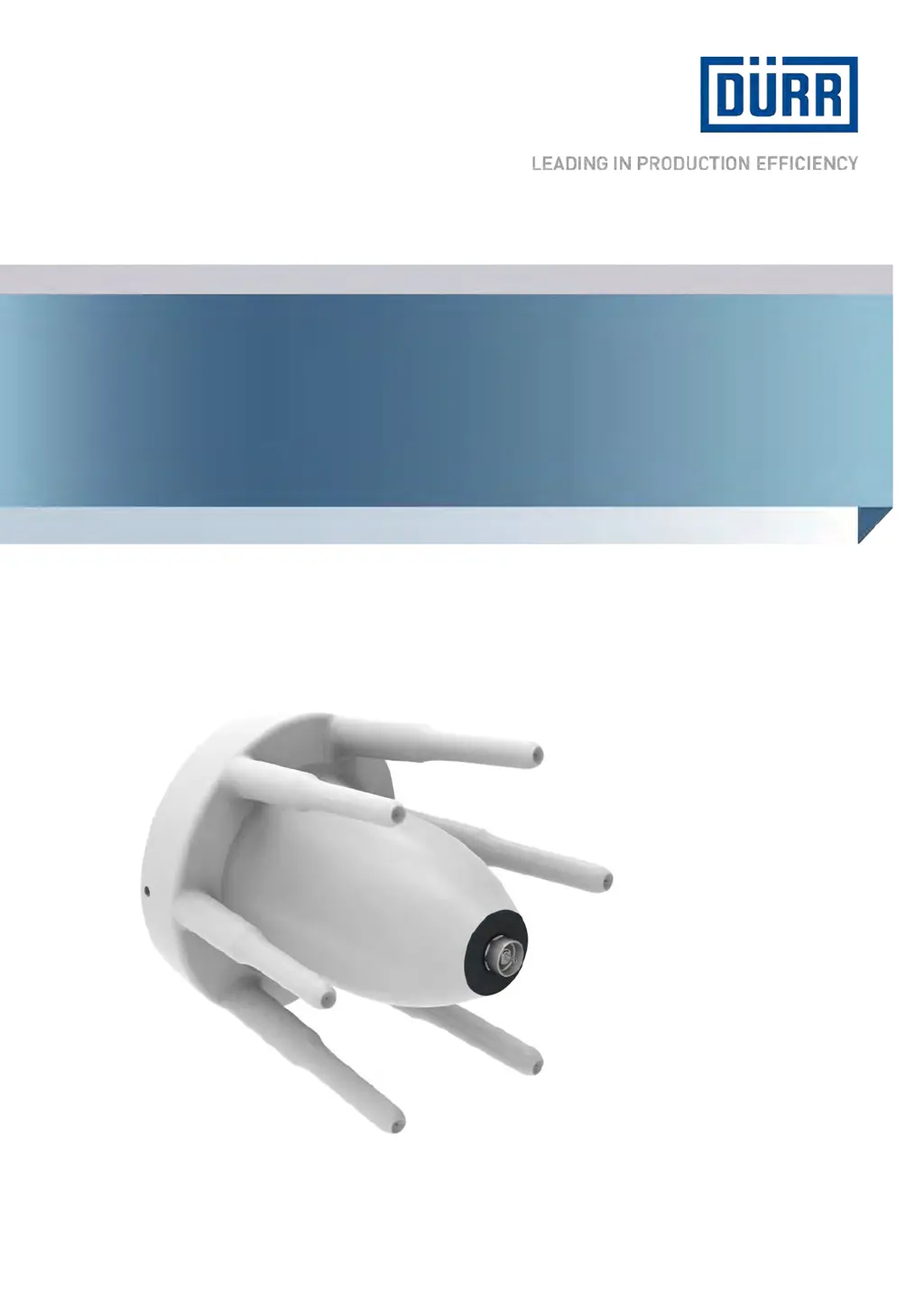

If your DÖRR Electronic Cigarettes atomizer isn't working correctly, several issues could be the cause. It might be due to a missing, damaged, or dirty bell disk. Ensure the bell disk is correctly installed, cleaned, or replaced as needed. Also, check the distance between the control air ring and the bell disk, ensuring the atomizer body, paint tube, turbine, and valve block are correctly installed. A dirty or damaged shaping air ring can also cause problems, so clean the shaping air ring or replace the atomizer body if it's damaged. Finally, check for a blocked nozzle, cleaning or replacing it as necessary, and ensure the turbine speed is correct.