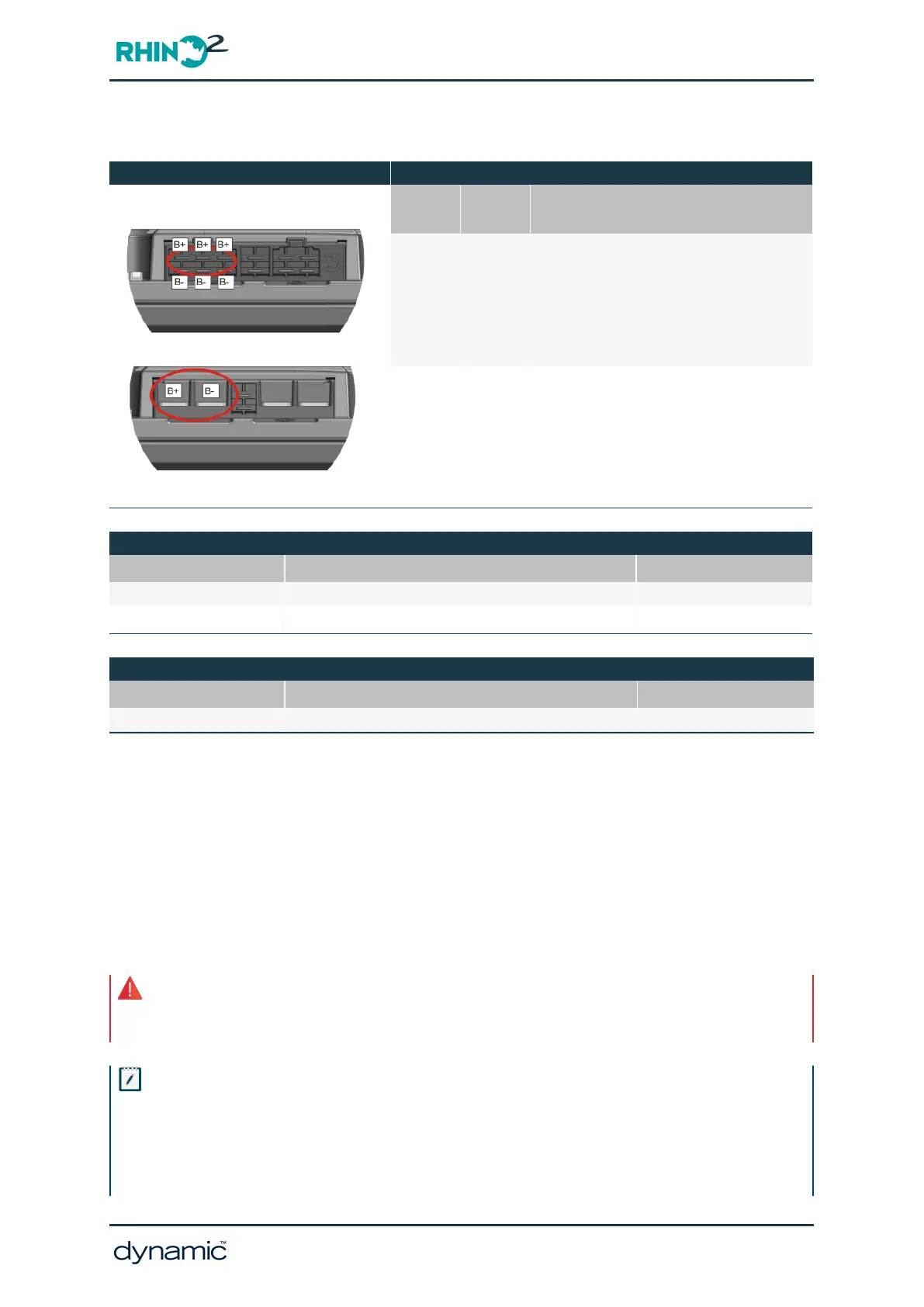

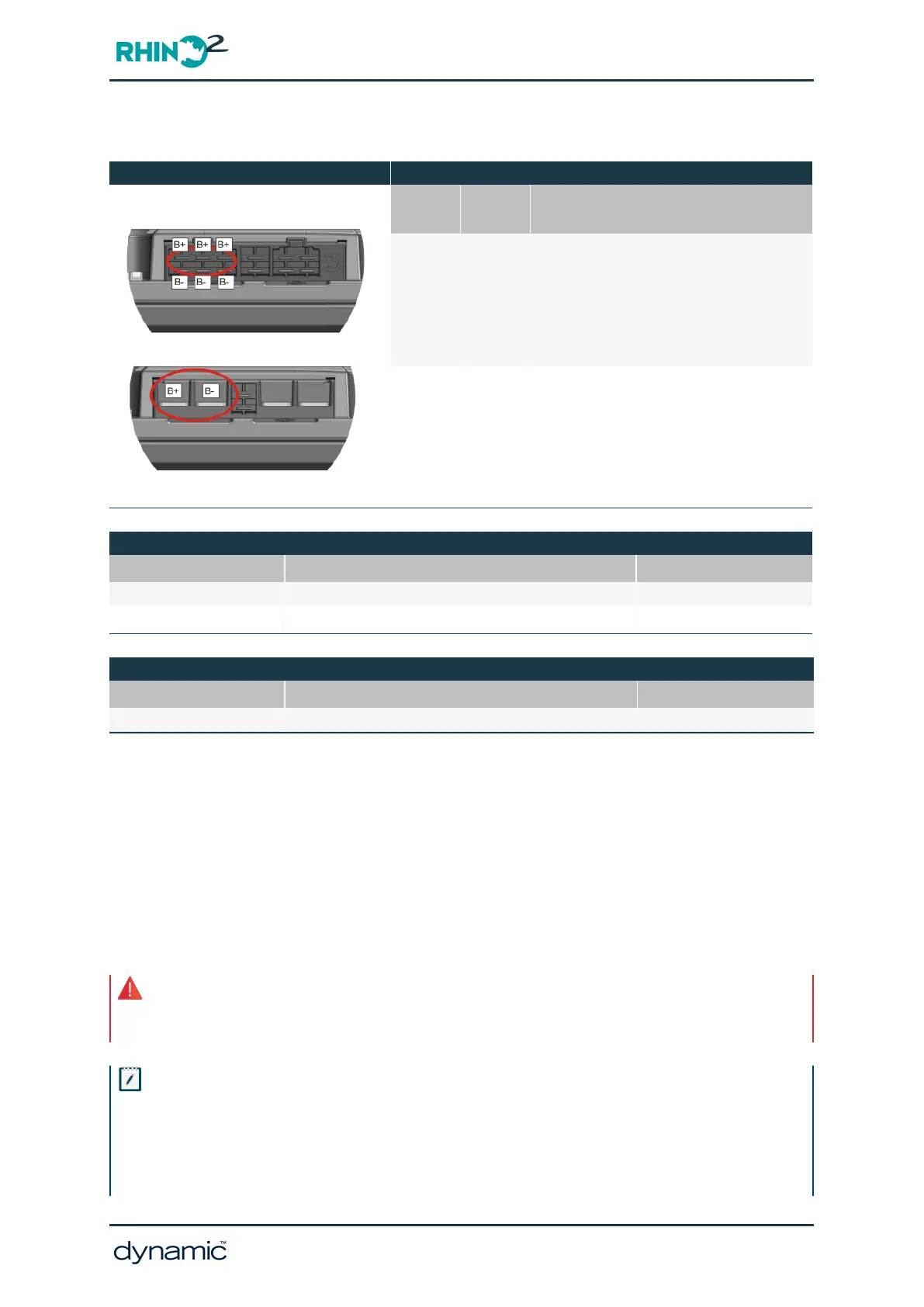

5.4 Battery Connections

Battery connections

Pin Function

Minimum Wire Gauge

(see notes below)

B+

Battery

Positive

DS90: 2 x 3mm

2

(2 x 12 AWG)

DS120: 2 x 3mm

2

(2 x 12AWG)

DS160: 2 x 5mm

2

(2 x 10AWG)

DS180: 2 x 5mm

2

(2 x 10AWG)

B-

Battery

negative

DS90: 2 x 3mm

2

(2 x 12 AWG)

DS120: 2 x 3mm

2

(2 x 12AWG)

DS160: 2 x 5mm

2

(2 x 10AWG)

DS180: 2 x 5mm

2

(2 x 10AWG)

Mating Connector Part Numbers DS90, DS120

Dynamic Part # Part Description Supplier Part #

GCN51971 6W Housing 250 Series Plug V0 N/A

GCN0690 Terminal Female 12-14AWG 170258-2

Mating Connector Part Numbers DS160, DS180

Dynamic Part # Part Description Supplier Part #

GCN1286 Crimp terminal M5 ring yellow 10-12AWG 2-130171-1

The length of the battery leads should be as short as possible, and the gauge should be as

heavy as possible to minimise the combined resistance of the battery wires and fuse, which

in turn will help minimise the overall voltage drop under heavy load. The wire gauge

recommendations given above are the MINIMUM gauge and are generally suitable for runs

up to 800mm. Longer runs will require heavier wire – typically an extra 1.0mm

2

for each

additional 400mm run length. The heavier the wire, the better driving performance will be.

These notes are in addition to the general wiring recommendations as described in Section

5.3.1 General Wiring Recommendations.

Warning

The RHINO2 system has been designed to perform optimally with either absorbed glass mat or Gel Cell 24 V

deep cycle lead-acid batteries, rated between 20 - 120 Ah.

Note

The final connection to the Battery Positive (+) terminal should not be made until the scooter is completely

wired and ready for testing as described in the Testing section.

To comply with ISO requirements, a red wire for the Battery Positive must be used. This must be the only use of

a red wire in the controller installation.

GBK51948 RHINO2

Installation Manual Issue 5

Installation and testing - Page 23

Loading...

Loading...