Operation

4812165301.pdf2022-09-02

Preparation for connection

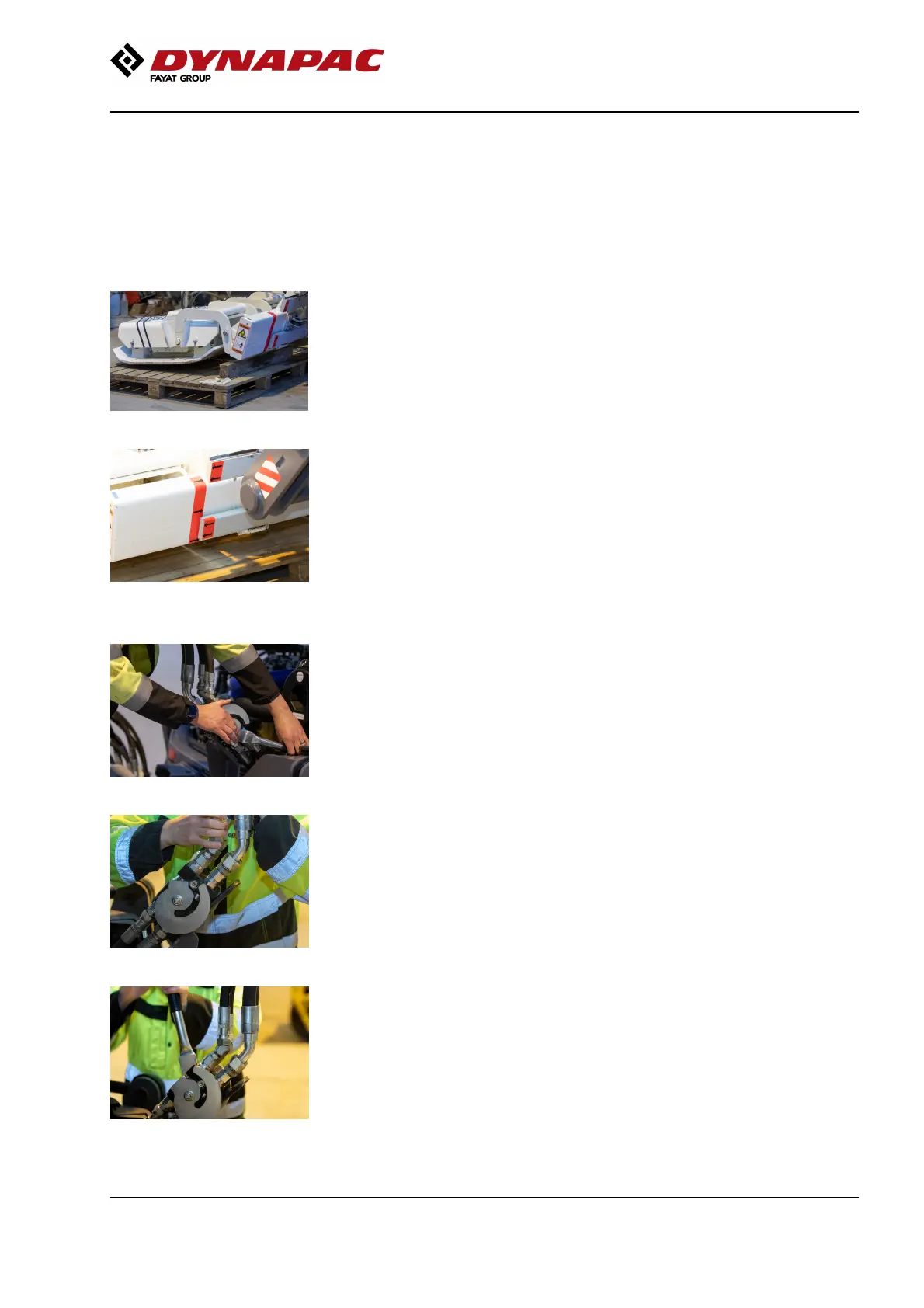

Make sure that the loose packing plates and

accompanying offset adjustment equipment are placed

on a wide pallet on a flat surface. The height of the

pallet must be between 10 and 20cm and cover the

underside of all three plates.

Two standard pallets/Euro pallets work in an

emergency.

The offset adjustment equipment’s transverse beam is

supported with a wooden beam or blocks so that the

beam is lifted approx. 70–100mm above the top of the

pallets.

The plates must be offset by approx. 500mm before

they are connected. This position is reached when the

arrow points on the decals align.

This ensures clearance between the lifting arms and

the hydraulic components of the plates.

If the plates are not offset adjusted, the hydraulics

must be connected before the plates are connected

mechanically to the roller’s lifting arms.

Switch on the hydraulics as follows:

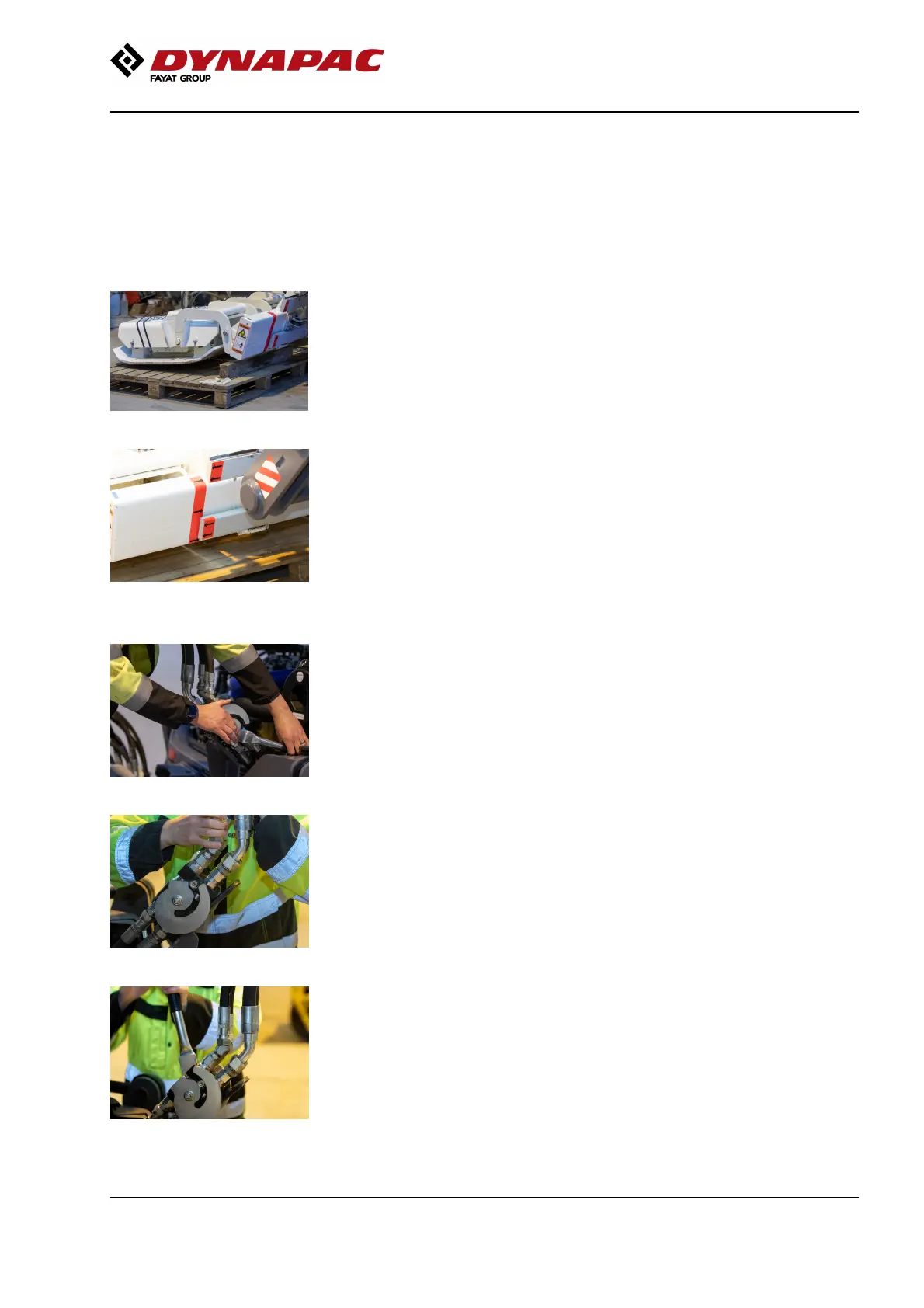

Open the roller’s motor hood. Expose the clamping

arm to the hydraulic quick-connector by pressing the

red button and then fold the clamping arm back.

Carefully remove any dirt from the contact surfaces of

the quick-connectors, both on the roller and on the

compaction plates, and fit the quick-connector halves

together.

The clamping arm must then be in the appropriate

position so that the pin on the side of the connecting

half from the packing plates is correctly positioned on

the left-hand side of the clamping arm. Then tighten

the clamping arm until it locks in the closed position.

79

Loading...

Loading...