Operation

4812165301.pdf2022-09-02

Operation and control

General

1

Fig. Control panel

1. Operating position

For operation and control of the plates, the roller must

first be moved into operating position by activating the

button for Operating position (1). When operating

position is active, a diode in the button lights up.

In this position, all the functions of the plates, as well

as the rest of the roller, are accessible. Exceptions

apply to raising the plates to transport position, for

example when loading and unloading, which can be

performed in any position.

Control

1

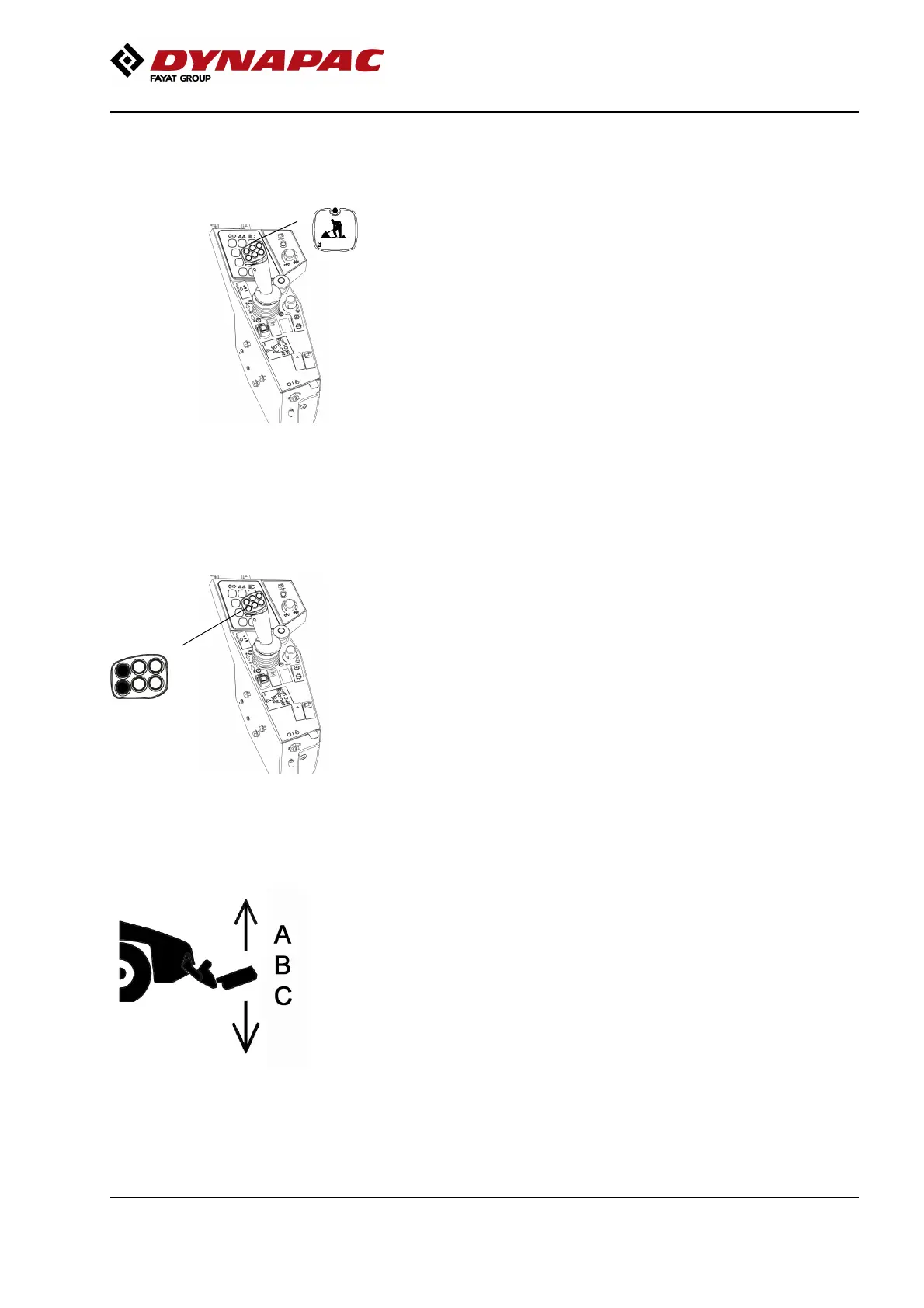

Fig. Control panel

1. Height adjustment buttons

The plates can be moved vertically between three

positions for which different conditions apply and

various functions are available.

All raising and lowering operations require the

intended movement control button to be pressed and

held until the next position is reached. Otherwise, the

operation will be aborted and the functions requiring

the position to be reached cannot be used until the

intended position is actually reached.

The three positions are:

• Transport position (A)

• Reverse position (B)

• Operating position (C)

A - Transport position.

This position is the highest and should be used when

moving the machine outside the immediate work field

and when loading and unloading, for example for

transport by truck. Raising to the transport position can

take place even when the roller is not in operating

position. The roller’s full transport speed is only

possible in this position. When raising offset adjusted

plates to transport position, they are first centered

before raising.

85

Loading...

Loading...