Maintenance - 1000h

4812165301.pdf2022-09-02

Maintenance - 1000h

Performed after 1000 operating hours (each year)

Park the roller on a level surface.

The engine must be switched off and the

parking brake activated when checking or

adjusting the roller, unless otherwise specified.

Park the roller on a level surface.

The engine must be switched off and the

parking brake activated when checking or

adjusting the roller, unless otherwise specified.

Ensure that there is good ventilation (air

extraction) if the engine is run indoors.

Risk of carbon monoxide poisoning.

Ensure that there is good ventilation (air

extraction) if the engine is run indoors.

Risk of carbon monoxide poisoning.

Hydraulic filter - Replacement

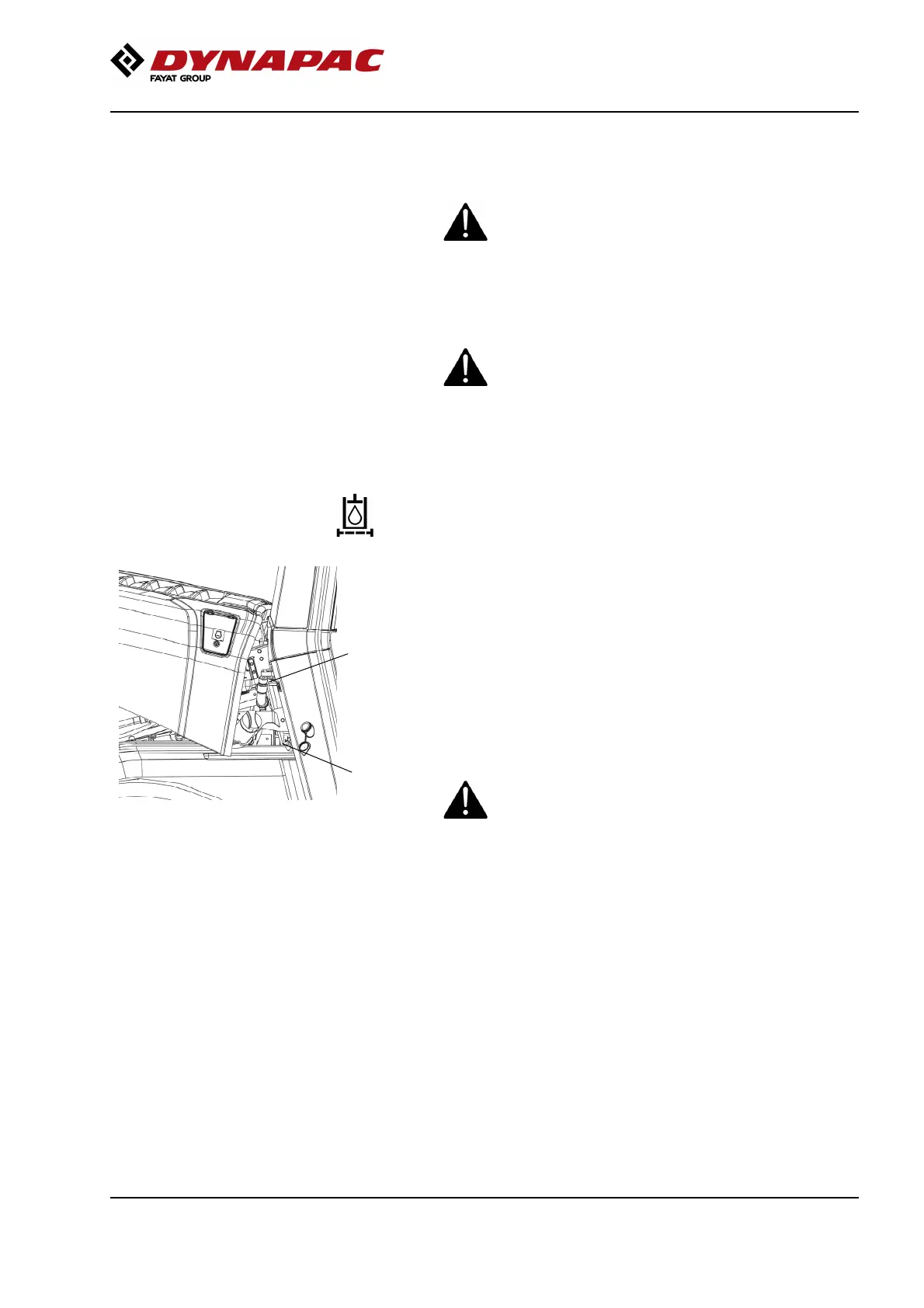

Fig. Hydraulic reservoir

2. Filler cover/bleeder filter

3. Sight glass

2

3

Undo the filler cap/bleeder filter (2) on top of the

reservoir so that over-pressure inside the reservoir can

be eliminated.

Make sure that the bleeding filter (2) is not clogged, air

must have unobstructed passage through the cap in

both directions.

If passage in either direction is blocked, clean the filter

with a little diesel oil and blow through with

compressed air until the block is removed, or replace

the cap with a new one.

Wear protective goggles when working with

compressed air.

Wear protective goggles when working with

compressed air.

139

Loading...

Loading...