4.4 Overfill protection

The Connexx system has double protection against the overfilling of the lifting vessel.

The normal suction cut-off is done using control unit. As soon as the float in the lifting

vessel is pushed upwards by an inflowing product, the solenoid valve closes and thus the

compressed air supply to the injector is interrupted.

The level switch contact is closed in the upper position. In case of cable breakage, the

control unit detects shortage of product, even if the lifting vessel is filled, and starts the

suction for the set time. After this time, it leads to alram i.e. switch-over to the second

container

.

To prevent significant quantities of product from flowing through the injector into the

exhaust air area in the time following a cable breakage or solenoid valve malfunction, the

suction opening in the cap is sealed with a mechanical float. A small quantity of product

may flow into the exhaust air until it closes. Thus it is absolutely necessary to have the

connection of exhaust air pipe (DN20) in a safe area

Ä

Chapter 4.2.3 ‘Compressed air

supply and exhaust air connection’ on page 18.

After rectifying the defect, the float must be brought back to the lower position before the

next commissioning. For this, you need to swivel the throttle screw completely out of the

thread. The float should then loosen itself with pressure equalisation.

If the float does not fall down with its own weight, then you can assist it e.g.

either by tapping with finger on the throttle opening or with some compressed

air.

The position of the float can be controlled using the suction openings on the side. When

the float is at the bottom, you can see through the openings.

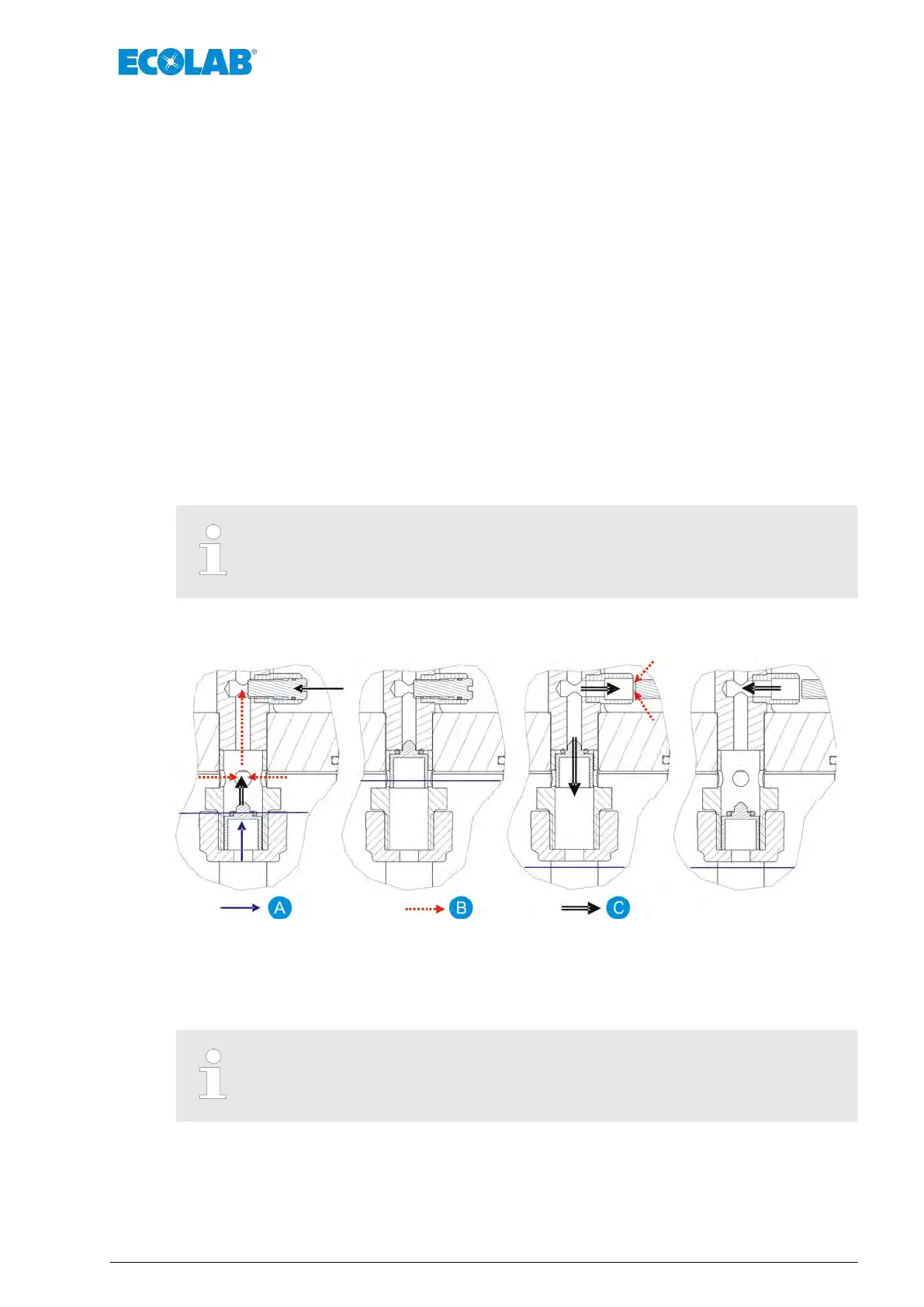

Fig. 9: Overfill protection

A Product level

B Gas/ air

C Movements

Since the equipment is being transported, it is possible that the float remains

hanging in the upper position. This should be checked before commissioning.

Functional description

21 Rev. 1-06.2018

Loading...

Loading...