n Distance between equipment and product storage housing as less as possible

(length of the suction hose max. 3 m!)

For a better venting, the suction line should

always be designed upward in the direction of lifting vessel.

n If the metering point lies below the lifting vessel, a pressure control valve or metering

valve with corresponding opening pressure must be used, in order to avoid thedraining

of lifting vessel through the pump(s).

n In order that while dealing with the Click & Plug connection coupling or through

suspended

suction hoses, there are no high loads on the

Connexx System and the

coupling connection on the containers, it is recommended to mount a pull relief for the

suction hose.

n The installation site should be selected in such a way that the exhaust air line from the

injector can be run into a safe area. Very long suction lines can reduce the

suction power of the injector and necessitate an increase in the nominal diameter

(

Ä

Chapter 4.2.3 ‘Compressed air supply and exhaust air connection’ on page 18).

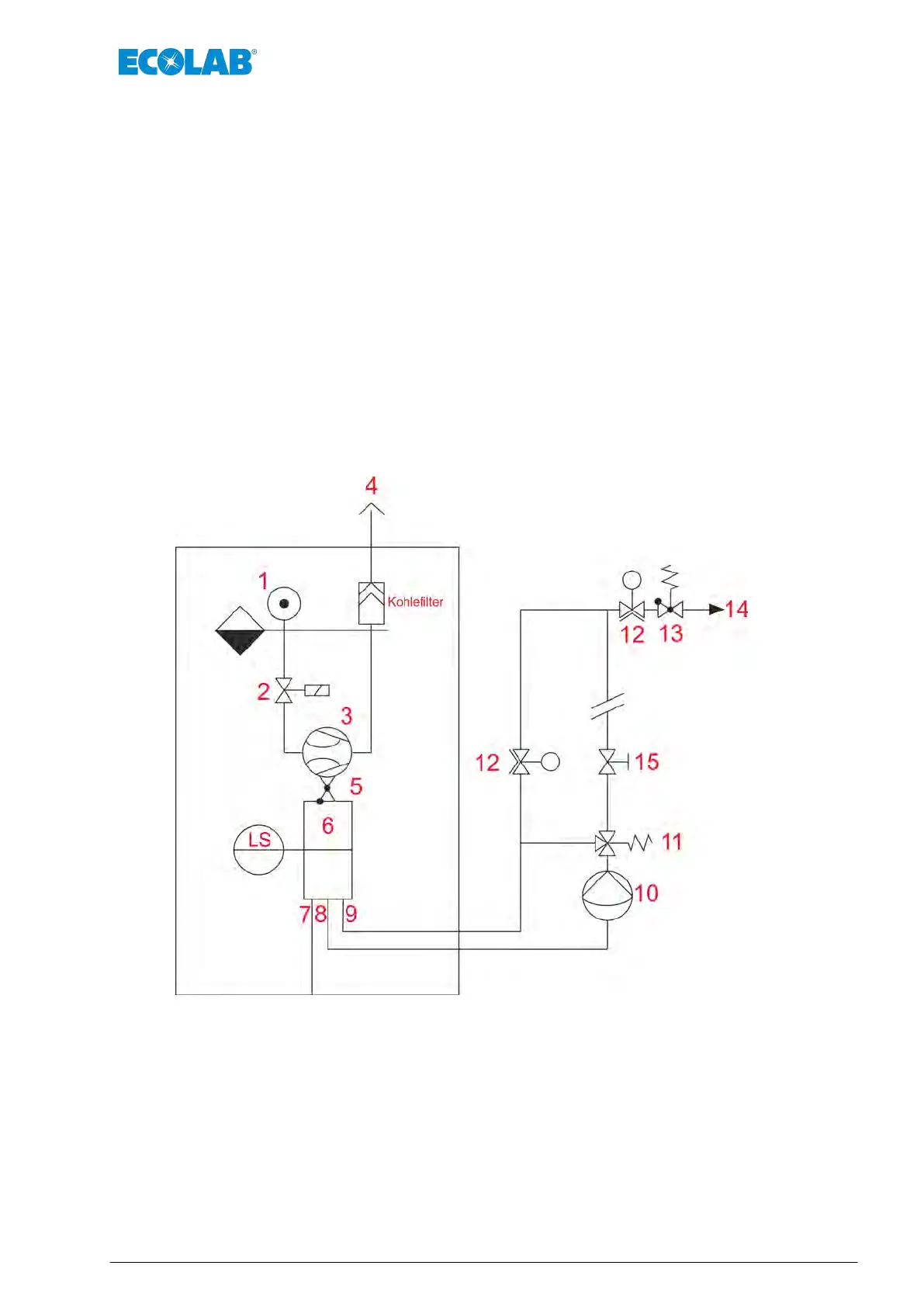

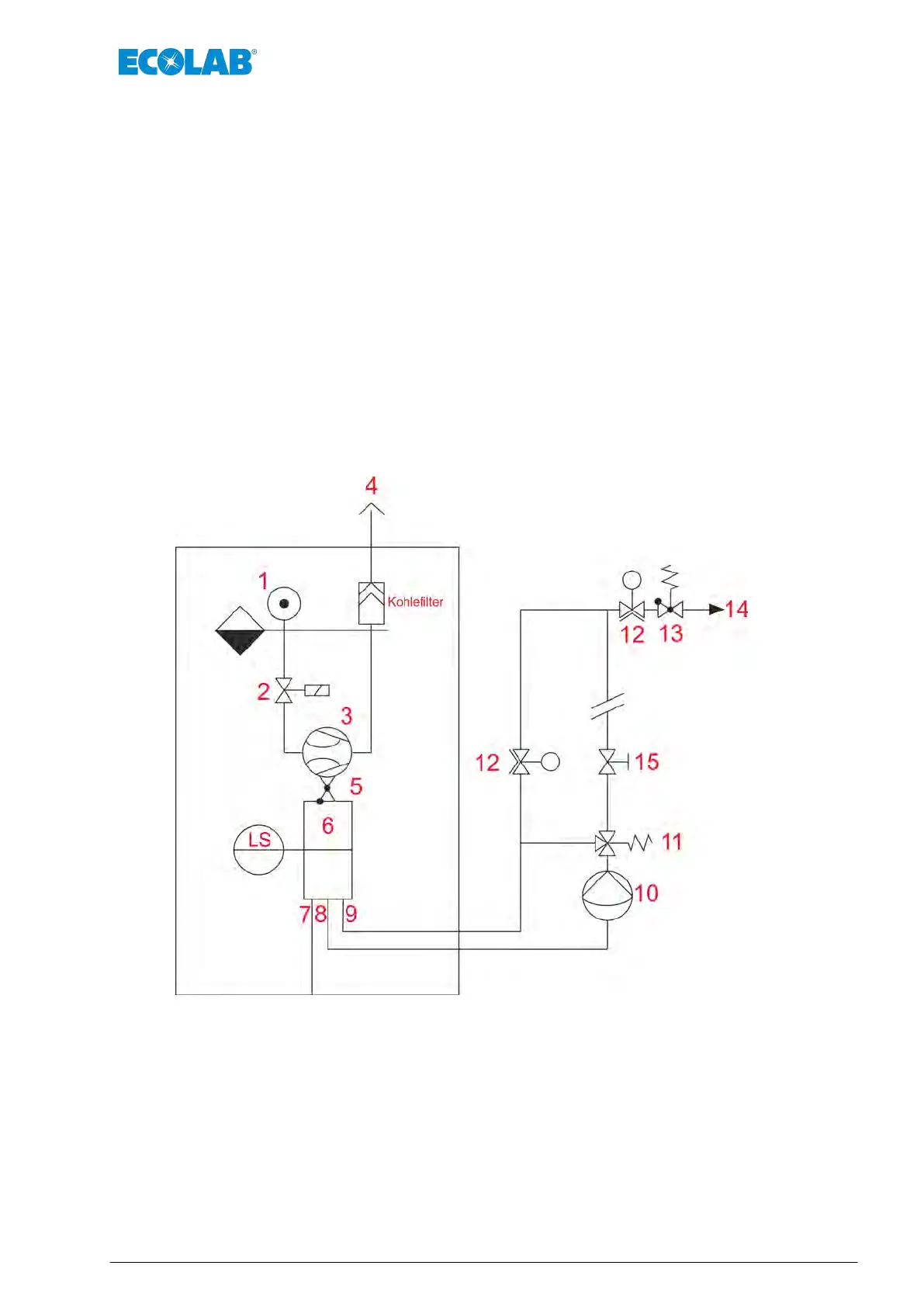

5.2 Protection when using a return connection

Fig. 14: Protection with return connection

1 Compressed air supply

2 Solenoid valve

3 Injector

4 Exhaust area

5 Non-return valve

6 Lifting vessel

7 Suction line container

8 Suction line pump

9 Return pipeline

10 Pump

11 Multi-function valve

12 Diaphragm valves (1 closed, if 2 open and vice versa)

13 Metering valve

14 Metering station

15 Diaphragm valve, hand-controlled

Assembly and Connection

29 Rev. 1-06.2018

Loading...

Loading...