CONFIGURATION OF KNOCK SENSORS PARAMETERS

EMU has the ability to work with common knock sensors and to take appropriate corrective actions

when knock is detected. Common correction strategies are to enrich the fuel dose and to retard

ignition timing. The EMU employs advanced knock processors designed for use with flat response

(wideband) knock sensors. Flat response knock sensors are able to capture much more

information than older style sensors, and advanced filtering and processing is performed by the

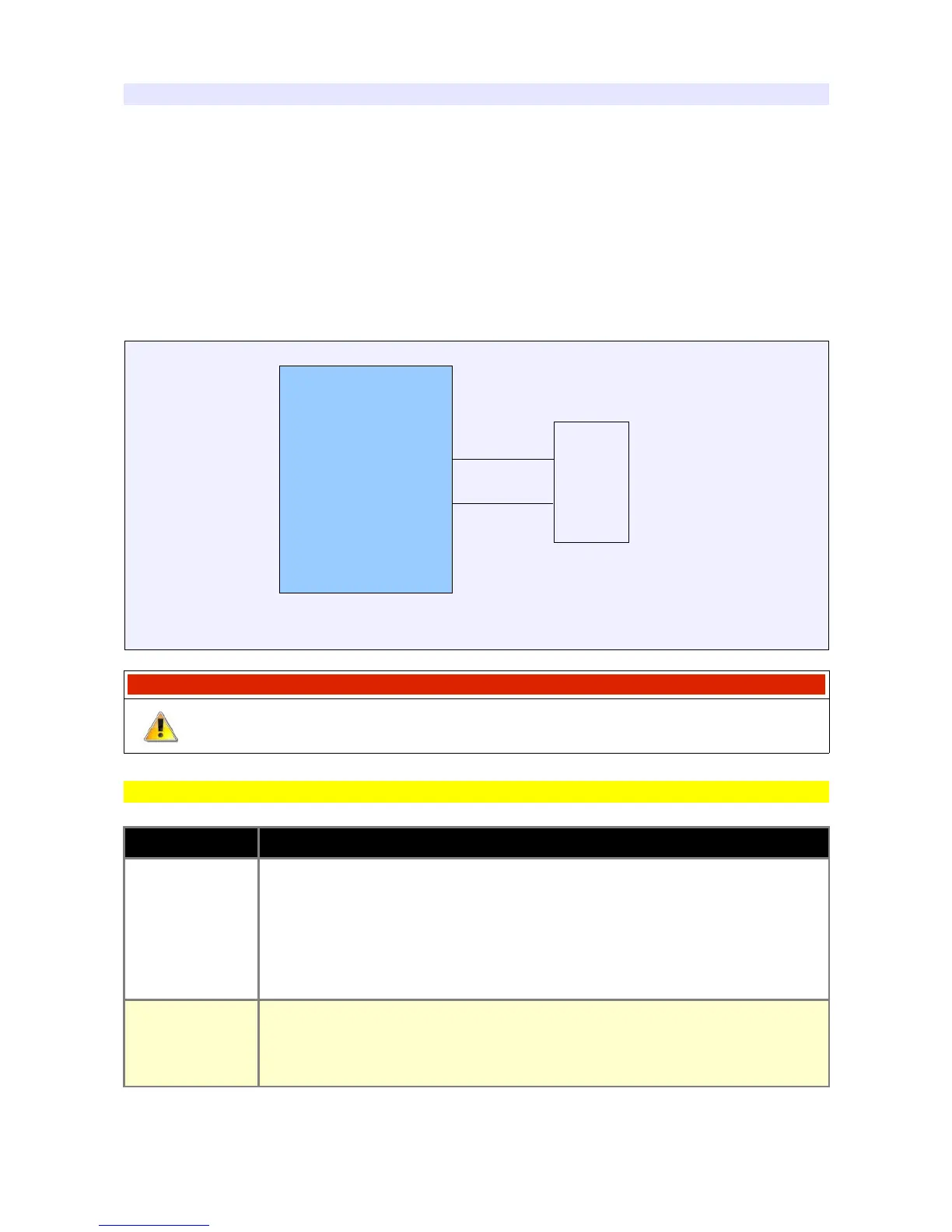

EMU in order to better detect knock. Connection for two-wire sensors is shown below. One-wire

sensors do not need a ground wire as the body of the sensor is grounded by mounting to the

engine block.

ATTENTION !

Knock sensors must be connected with shielded cables. Shielding must be

connected to ground on only one end.

Sensor parameters

PARAMETER DESCRIPTION

Knock

frequency

The engine knock characteristic frequency used to configure the band-pass

filter. This characteristic is different for every engine. It can be approximated

with the following equation:

Knock frequency (kHz) = 1800/(Pi * D)

Where D is cylinder diameter in millimeters

Gain

Knock sensor signal gain should be adjusted so that the Knock sensor value

parameter doesn't exceed 3V across the full RPM range during normal

combustion

Page 101

EMU

B2

KS

Knock sensor sample connection

B18

GND

Out

Loading...

Loading...