VVT – Variable Valve Timing

Typical variable valve timing system is based on PWM controlled solenoid that regulates the oil

pressure applied to an actuator to adjust the camshaft position.

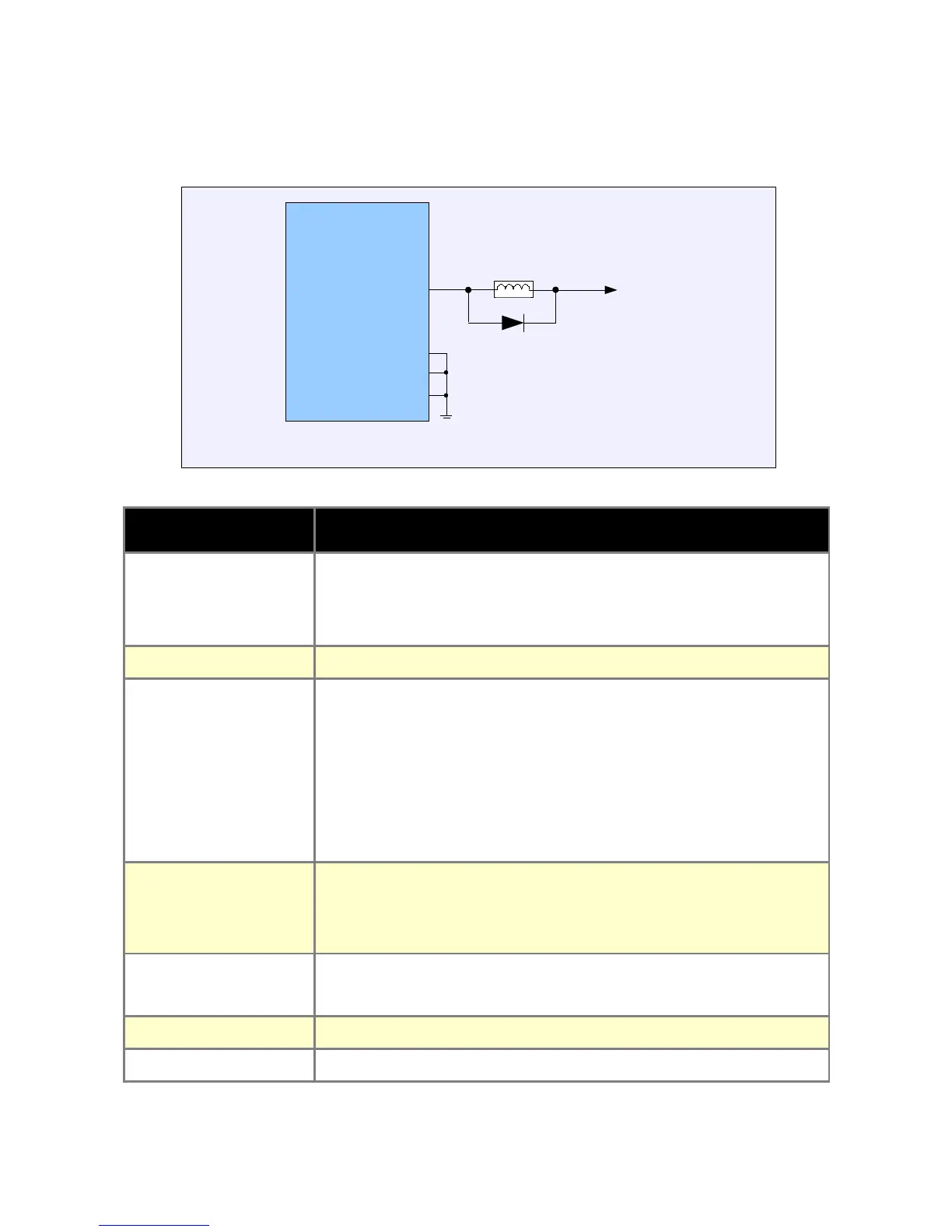

PARAMETER DESCRIPTION

CAM Offset

This parameter is used for camshaft starting position calibration.

The correct value should be chosen to make Cam #1 angle log

channel equal to 0 deg, when the solenoid is not powered

Max. retard / advance Maxim allowable value to retard / advance the camshaft position

Control type

VVTi - control of camshaft position is based on one solenoid.

Dependant of control signal DC (duty cycle) camshaft position

can be advance or retard.

Double Vanos - the control of camshaft position is based on two

solenoids. Each solenoid is responsible for moving the camshaft

position in one direction

Solenoid output #1

Output used for camshaft control solenoid (VVT) or one of the

Double Vanos solenoids

Solenoid output #2 Output used for second camshaft control solenoid of the Double

Vanos system

Output frequency The frequency of signal controlling solenoid

Steady pos DC In the case of VVT system based on one camshaft control

Page 106

EMU

G12

G17

G24

B24

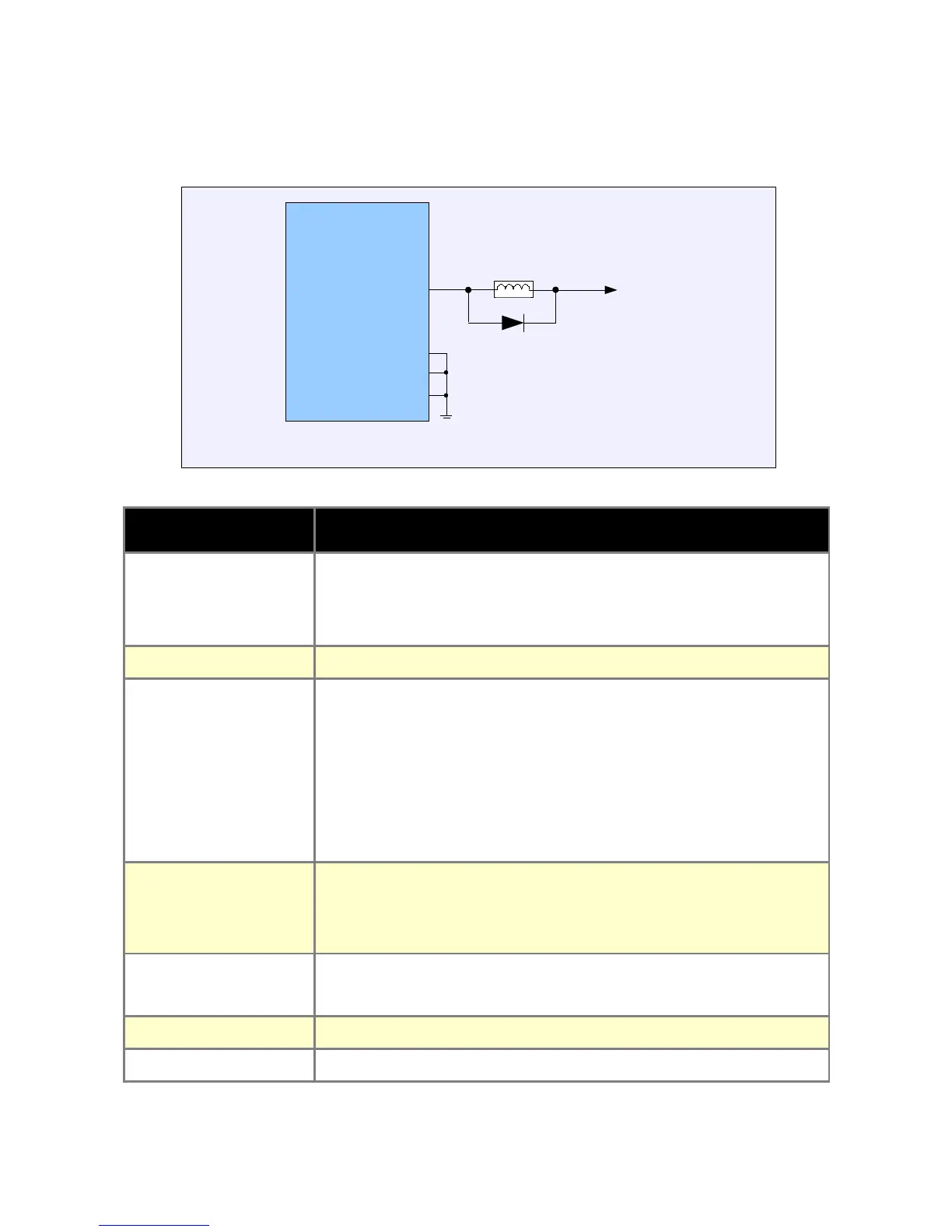

Sample connection of single PWM VVT control solenoid

+12V

Loading...

Loading...