Piping

37 Liebert

®

SRC™ User Manual

4. Carefully inspect the flared pipe end.

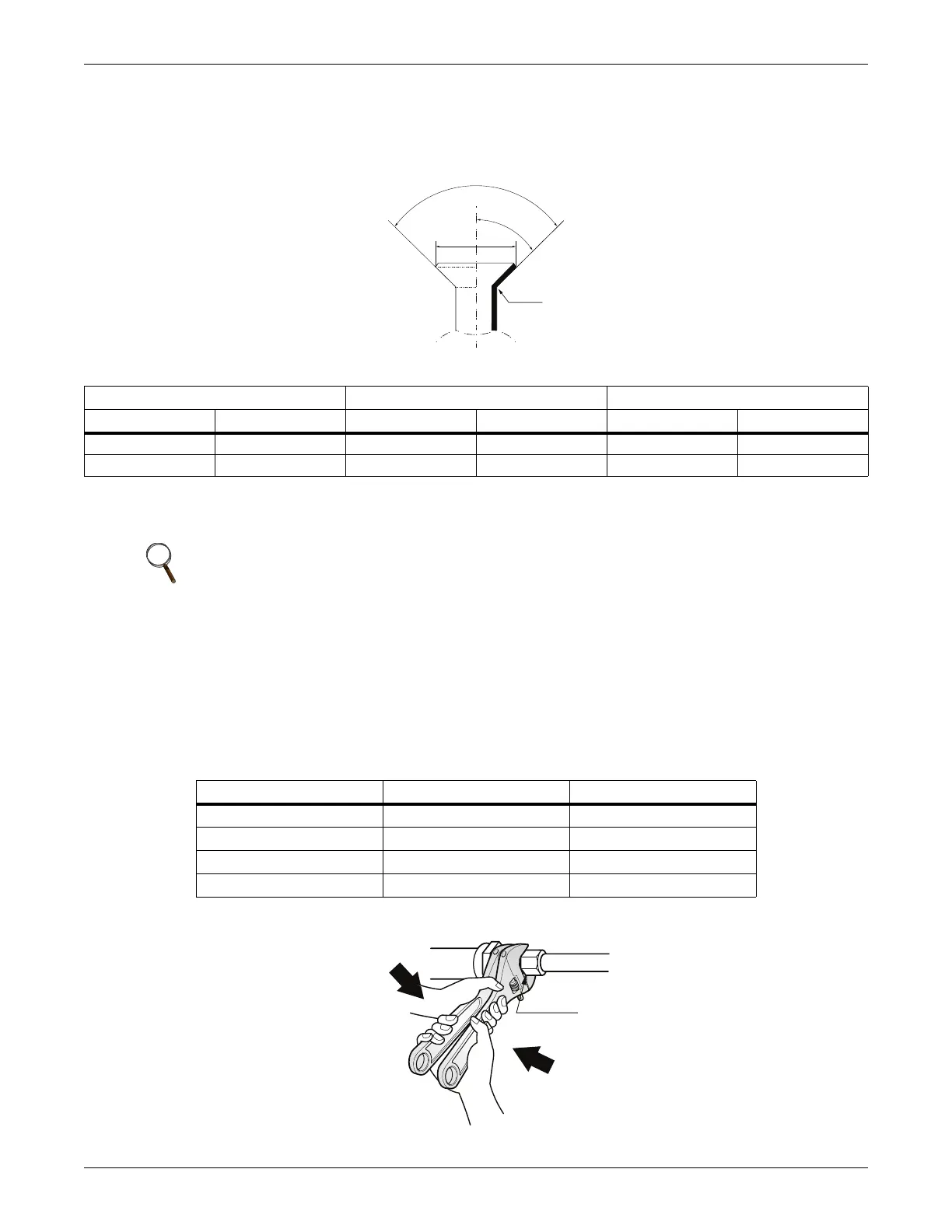

• Compare the geometry with Figure 5-1 and the dimensions detailed in Figure 5-2 and Table 5-1.

Figure 5-2 Flared-connection dimensions

5.1.2 Tightening Flare Nuts

1. When connecting the flare nuts, coat the flare (inside and outside) with polyvinyl ether (PVE)

refrigeration oil only.

2. Initially, hand tighten the flare nuts using 3 or 4 turns.

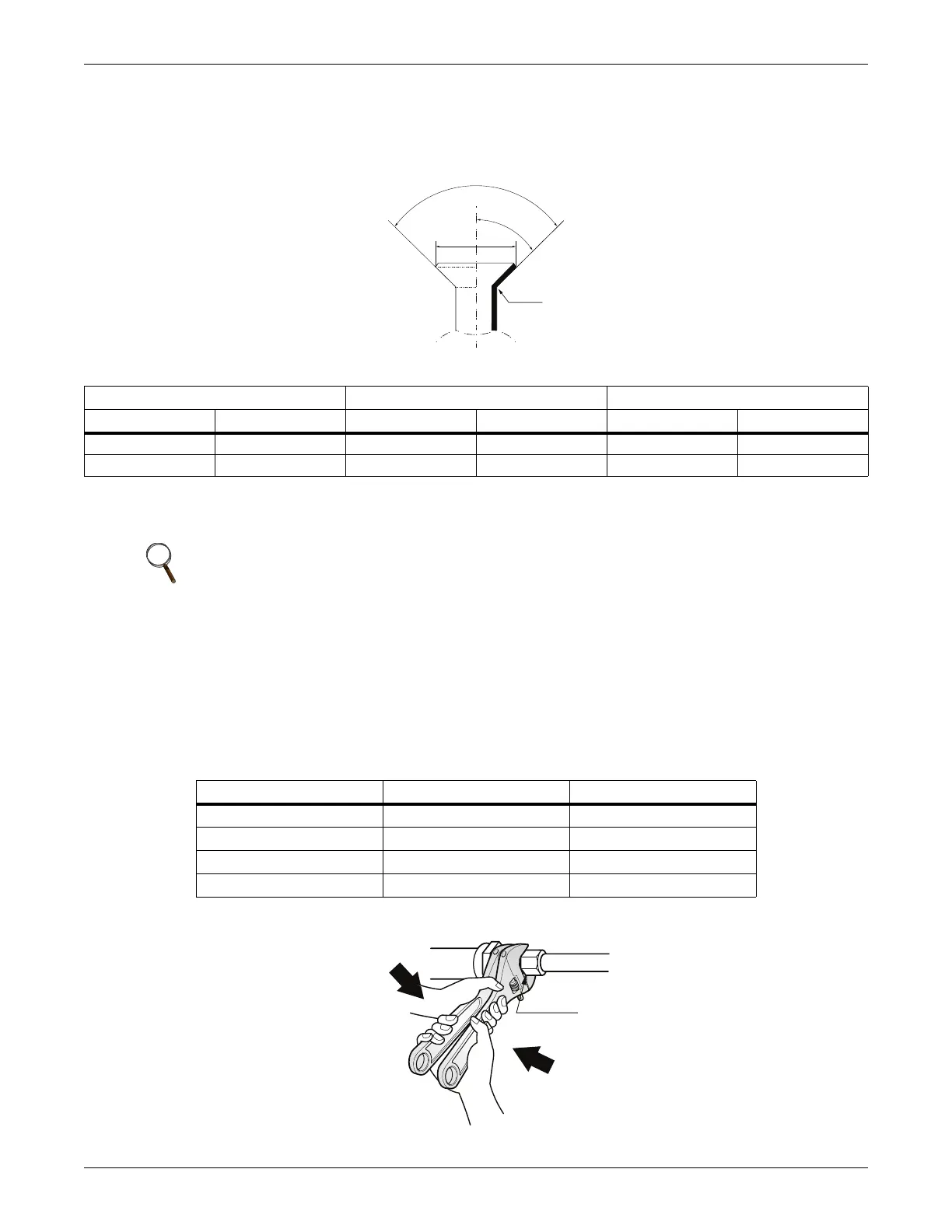

3. Finishing tightening the flare nuts using both a torque wrench and a backup wrench as shown in

Figure 5-3.

Figure 5-3 Tightening the flare nuts

Table 5-1 Flared-connection dimensions

Pipe “A” Thickness

Vapor (in. O.D.) Liquid (in. O.D.) Vapor (in.) Liquid (in.) Vapor (in.) Liquid (in.)

1/2 1/4 1/8 1/16 1/8 1/8

5/8 3/8 1/8 1/16 1/16 1/8

NOTE

Do not use polyolyester (POE) or any other type of mineral oil as a thread

lubricant. These lubricants are not compatible with PVE oil used in this system

and create oil sludge leading to equipment damage and system malfunction.

Table 5-2 Tightening torque for flare nuts

Pipe size (in. O.D.) Tightening torque (ft-lbs) Width of flare (A [in.])

1/4∅

13.9 – 18 1/8

3/8∅

24.5 – 30.3 1/8

1/2∅

39.7 – 47.7 1/8

5/8∅

45.5 – 59.2 1/16

Union

Loading...

Loading...