Emerson Process Management GmbH & Co. OHG1-2

X-STREAM X2FD

Instruction Manual

HASXMDE-IM-EX

01/2015

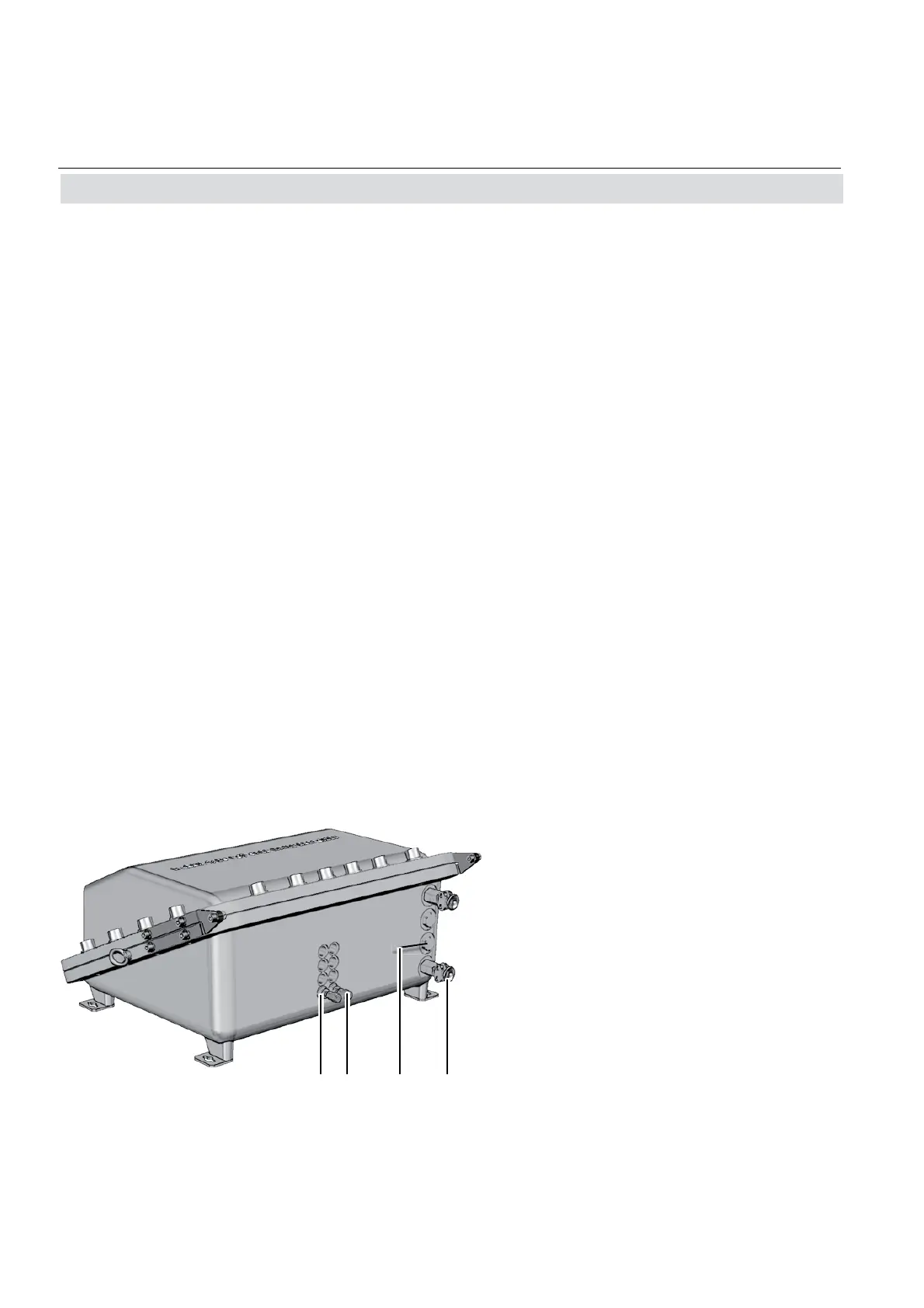

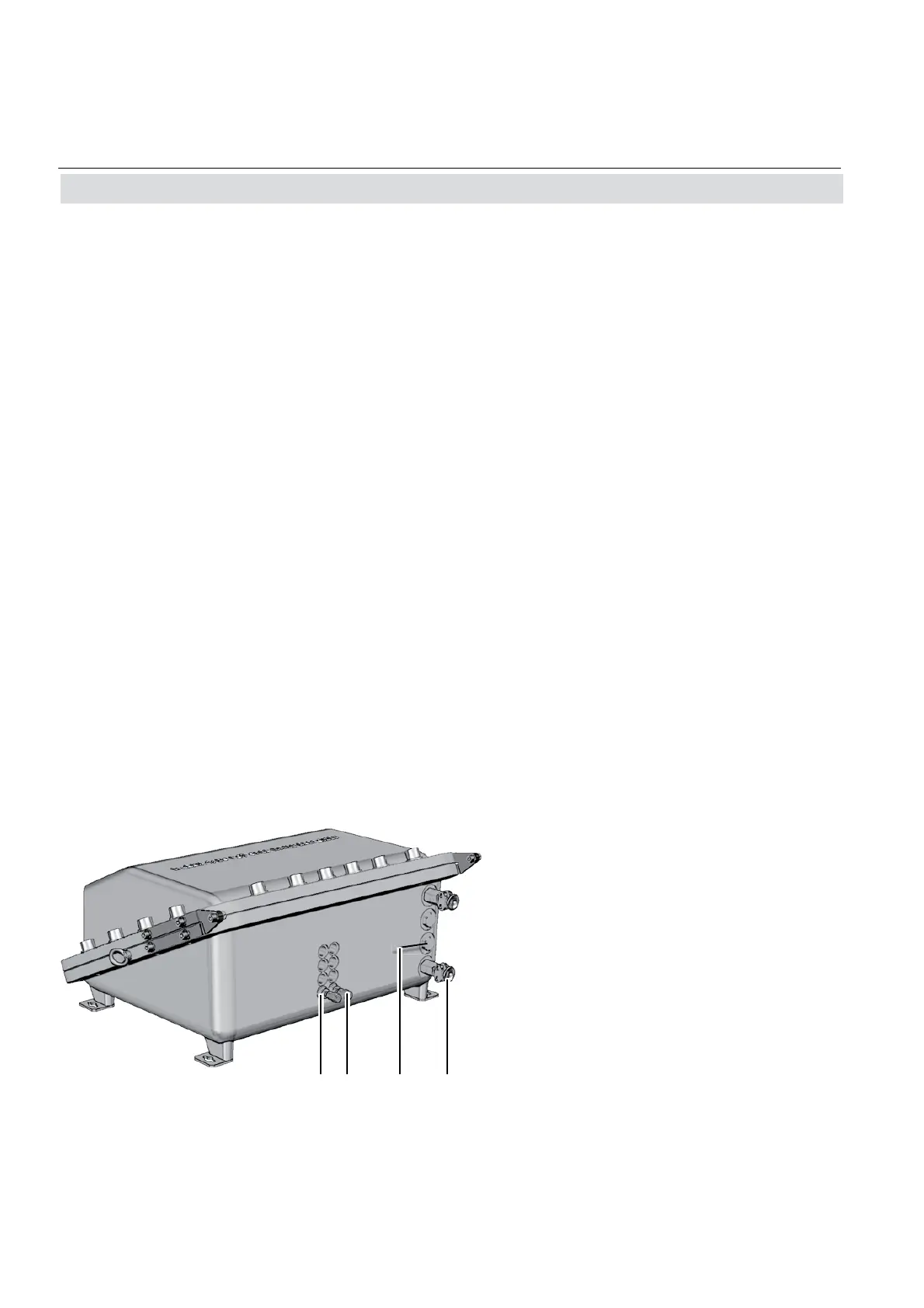

1.3 Protective Measures in Detail

The cast aluminum enclosure consists of

two parts: base and cover, connected by

hinges.

The area where the two parts are in contact

is designed to work as a fl ange, quenching

fl ames entering the small path between them.

When operated, the analyzer enclosure has to

be closed and secured by 20 screws evenly

arranged all over the fl ange. The only ope-

nings penetrating the enclosure are threads,

to be used for gas and cable in- and outlets:

Depending on the measurement application

the instrument provides up to 8 gas in- and

outlets, each protected by an approved fl ame

arrestor. These arrestors are installed into

threads at the bottom side of the enclosu-

re base. Two fi tting sizes are available for

external connection of gas pipes with 3,18

mm (1/8“) or 6,35 mm (1/4“) outer diameter

(OD). Optionally a clamping ring for 6 mm

OD may be used, replacing the 6,35 mm

version. Unused threads are closed with blind

plugs which are certfi ed within the emerson

approvals.

Cables are fed into the enclosure utilizing up

to 4 cable glands, located at the enclosure`s

bottom right side.

For installation in North America cable glands

are replaced by a combination of conduits and

metric-to-NPT thread adapters.

All threads are designed to act as a fl ame

path of a length ensuring that possibly

entering flames are quenched before

exiting to the external atmosphere. For

this reason, avoid to damage the threads,

neither externally nor internally!

Unused threads must be closed with plugs

when the instrument is operated to ensure

explosion protection.

Note!

See the X-STREAM X2 series instruction

manual for more information about common

X-STREAM X2 series gas analyzers features

and special features of the X-STREAM X2FD.

Fig. 1-2: Bottom view

1: Plugged when not used (plugs cer-

tifi ed by emerson)

2: Gas fi tting (part of fl ame arrestor)

3: Plug

1

234

1.3 Protective Measures in Detail

Loading...

Loading...