Emerson Process Management GmbH & Co. OHG 2-9

2

Installation

X-STREAM X2FD

Instruction Manual

HASXMDE-IM-EX

01/2015

1

2

3

4

5

5

6

7

Gas inlets and outlets are protected by fl ame

arrestors, supporting stainless steel pipes of

either 3,18 mm (

1

⁄8“) or 6,35 mm (

1

⁄4“) outer

diameter (OD). The

1

⁄4“ fi tting may optionally

be supplied with a clamping ring for 6 mm OD

pipes.

Fig. 2-5: Flame arrestor installed

into instrument enclosure

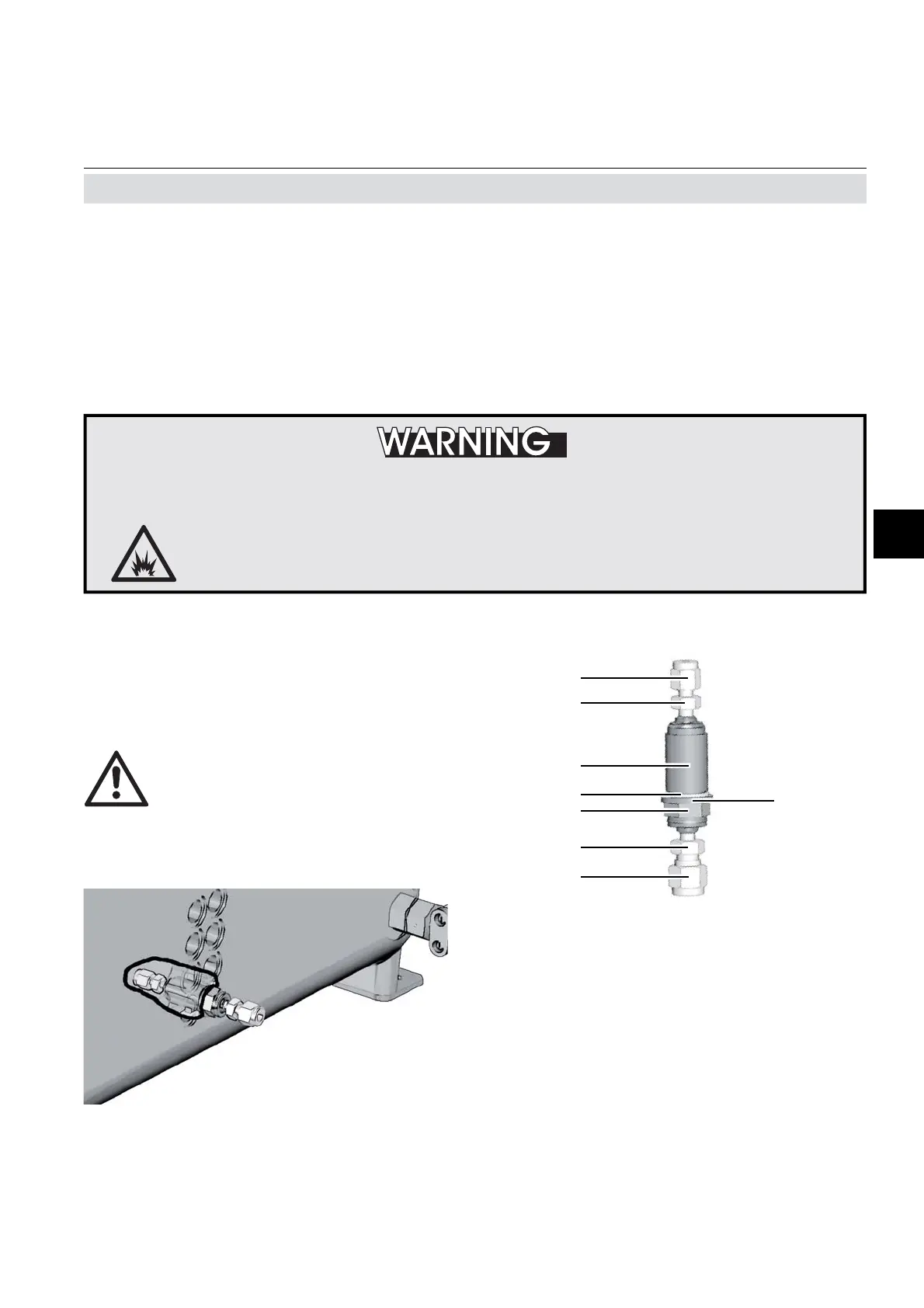

1: Gas fi tting

1

⁄8“ (inside instrument) *

)

2: M18 male threat (inside enclosure wall)

3: O-ring (optional)

4: Gas fi tting

1

⁄4“ or

1

⁄8“ (outside instrument) *

)

5: Hexagon for counter holding while thightening

6: Hexagon for wrench when mounting into a M18 threat

7: O-ring shoulder

*) FA 01 with

1

⁄4“ (outside instrument) and

1

⁄8“ (inside)

FA 02 with

1

⁄4“ at both ends

FA 03 with

1

⁄8“ at both ends

Fig. 2-6: Flame arrestor elements,

exemplarly considering FA 01

When thightening the fi tting, counterhold the

fl ame arrestor with a wrench placed at the

hexagon (items 5 of fi g. 2-3) next to the cap

nut (items 1, 4) to be tightened.

Always counterhold the fl ame

arrestor while thightening fi t-

tings; otherwise the fl ame arre-

stor may be damaged!

Maximum permitted fastening

torque: 40 Nm!

The instrument provides up to 8 gas inlets and

outlets, depending on the ordered confi gura-

tion. Unused entries are closed by approved

plugs.

POSSIBLE EXPLOSION HAZARD

Take care not to damage the threats, this may void the instrument´s safety

and cause hazards!

Ensure unused entries remain sealed with approved plugs!

2.4 Installation - Gas Connections

Loading...

Loading...