Emerson Process Management GmbH & Co. OHG1-18

X-STREAM X2FD

Instruction Manual

HASXMDE-IM-EX

01/2015

1.9 Vapor Recovery Application

1.9 Vapor Recovery Application (Simultaneous Measurement of CH

4

and Non-CH

4

)

This application is served by a special confi -

guration of the X-STREAM X2FD fl ameproof

analyzer.

Principle of measurement

The sample gas is taken towards a converter.

At it‘s inlet the gas stream is divided into two:

one is directly fed to a non-CH

4

measurement.

The other is supplied to a solenoid valve,

normally forwarding the gas to the converter.

Within the converter, hydrocarbons higher

than CH

4

are converted into H

2

O and CO

2

.

The converter outlet is connected to a second

IR measurement system, analyzing the re-

maing amount of hydrocarbons (mainly CH

4

)

in the sample gas.

After switching power on, wait

about 50 min. for the converter

to reach its operating tempera-

ture before applying gases!

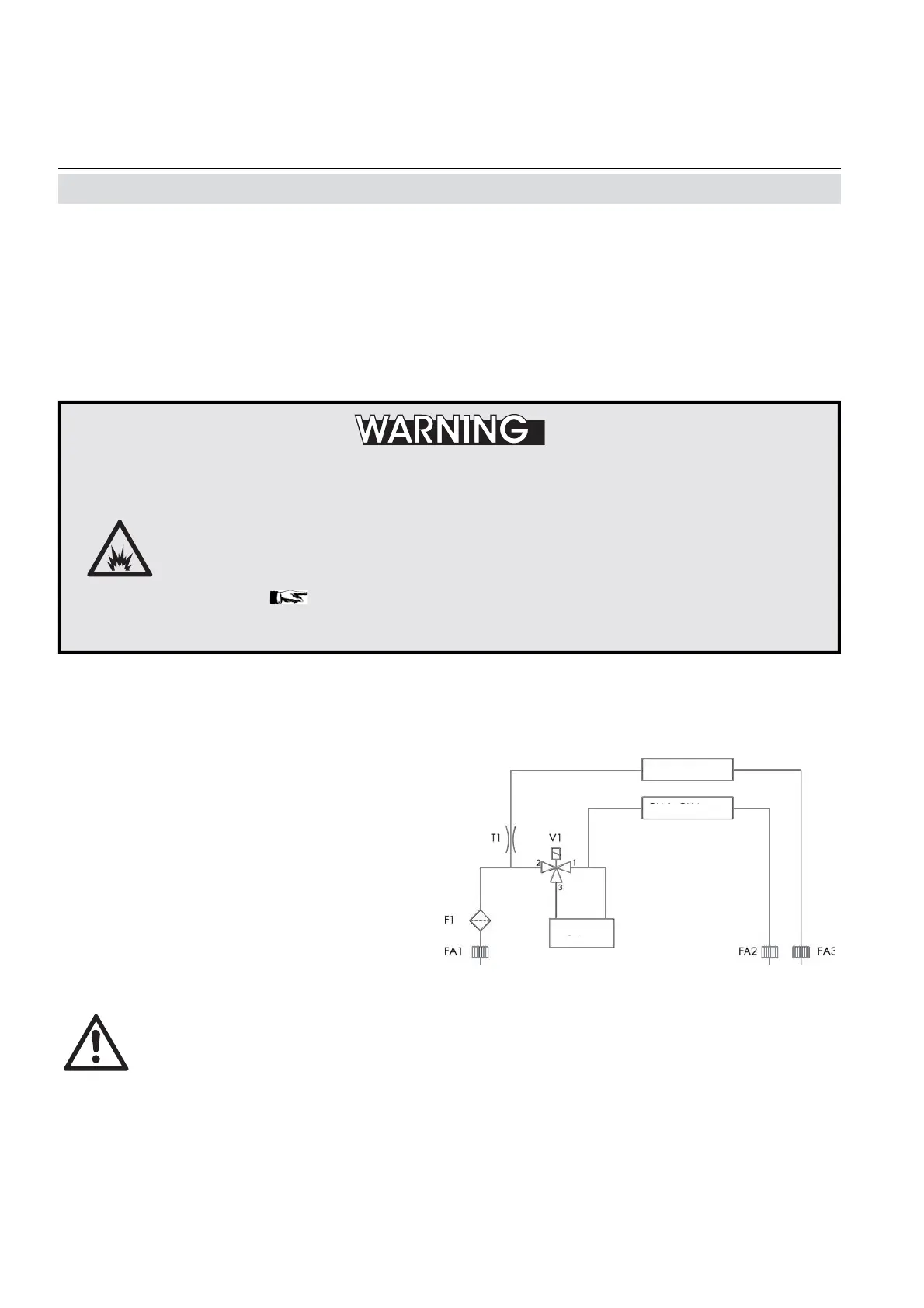

FA1: Analyzer‘s inlet fl ame arrestor

FA2...3: Analyzer‘s outlet fl ame arrestors

F1: Filter

T1: Throttle

V1: Valve

The confi guration consists of a dual channel

IR measurement, connected to the inlet and

outlet of a converter. This converter is instal-

led inside the X-STREAM analyzer and is

heated to about 280 °C (536 °F).

Fig. 1-7: Vapor Recovery Gas Flow Diagram

)$ )$ )$

&XWWHU

)

7

9

&+&+

&+&+

Converter

CH2: non-CH

4

CH1: CH

4

EXPLOSION HAZARD BY HOT COMPONENTS

Temperatures inside an analyzer for VAPOR RECOVERY applications exceed

the analyzer‘s temperature classifi cation for hazardous areas!

Special conditions apply to handling this analyzer, consider the safety

instructions at the beginning of this manual and the special conditions for

safe use

(

1-5)

Consider the waiting time statement on the front door label before opening!

Loading...

Loading...