Safety

Information

Introduction

Product

Information

System

configuration

Mechanical

Installation

Electrical

Installation

Getting

Started

Basic

parameters

Running

the motor

Optimization

SMARTCARD

operation

Onboard

PLC

Advanced

parameters

Technical

Data

Diagnostics

UL Listing

Information

100 Unidrive SPM User Guide

www.controltechniques.com Issue Number: 3

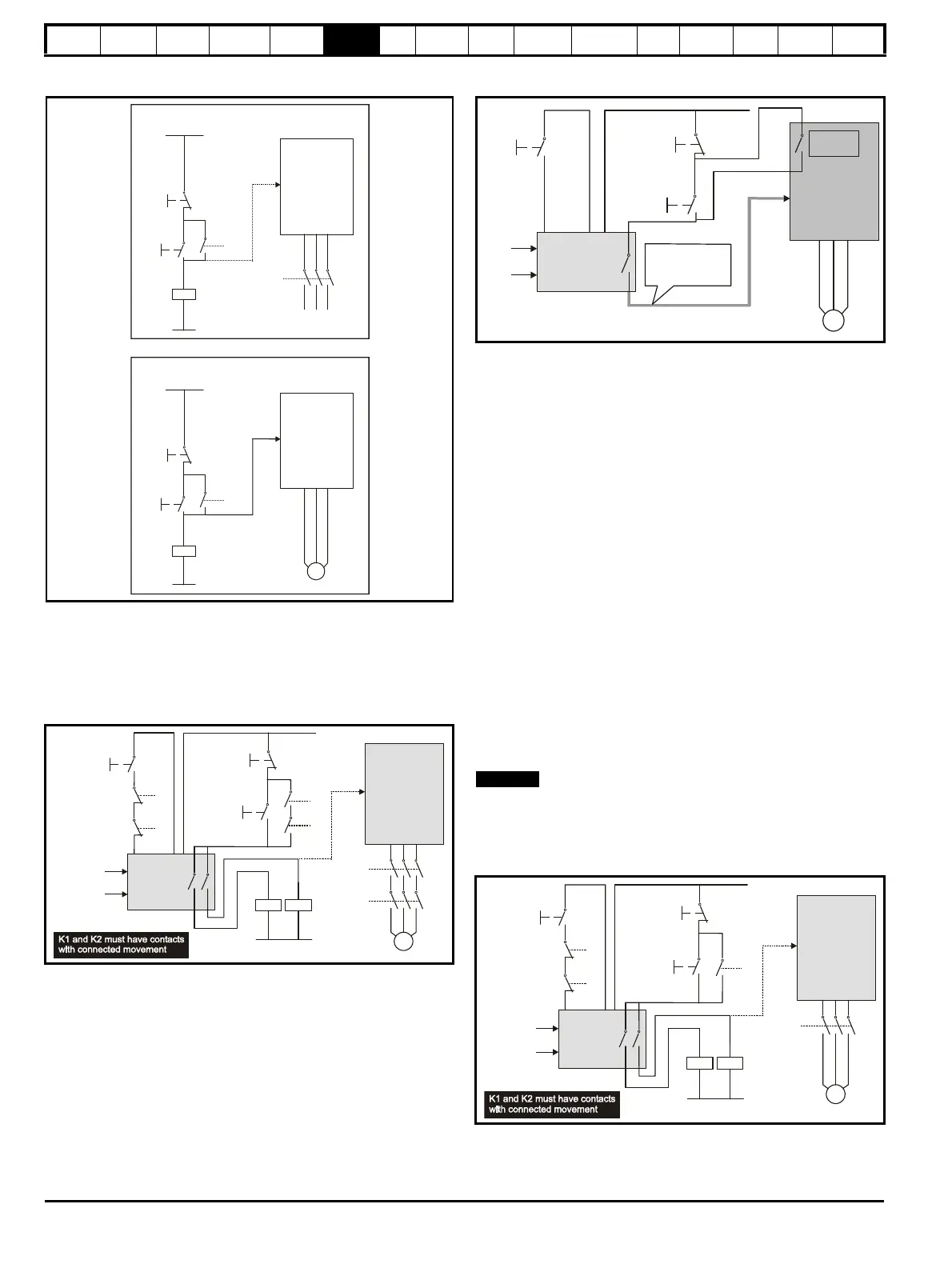

Figure 6-45 Start / stop control EN954-1 category B - replacement

of contactor

In the second example, illustrated in Figure 6-46 and Figure 6-47, a

conventional high-integrity system which uses two safety contactors with

auxiliary contacts with connected movement is replaced by a single

SAFE TORQUE OFF (SECURE DISABLE) system. This arrangement

meets EN954-1 category 3.

Figure 6-46 Category 3 interlock using electromechanical safety

contactors

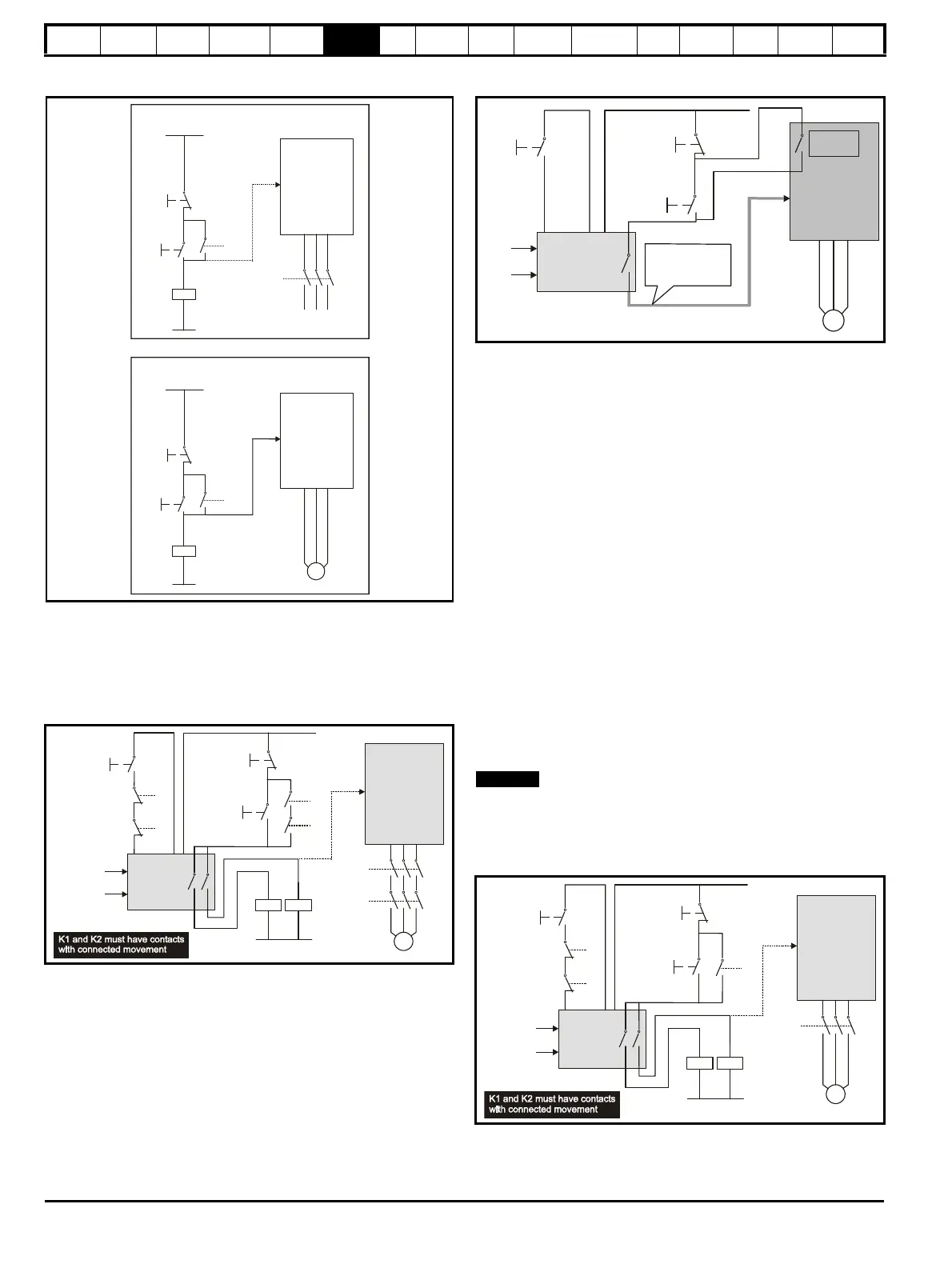

The safety function of the example circuit is to ensure that the motor

does not operate when the interlocks are not signalling a safe state. The

safety relay is used to check the two interlock channels and detect faults

in those channels. The stop/start buttons are shown for completeness as

part of a typical arrangement, they do not carry out a safety function and

are not necessary for the safe operation of the circuit

Figure 6-47 Category 3 interlock using SAFE TORQUE OFF

(SECURE DISABLE) with protected wiring

In the conventional system, a contactor failure in the unsafe direction is

detected the next time the safety relay is reset. Since the drive is not part

of the safety system it has to be assumed that AC power is always

available to drive the motor, so two contactors in series are required in

order to prevent the first failure from causing an unsafe event (i.e. the

motor driven).

With SAFE TORQUE OFF (SECURE DISABLE) there are no single

faults in the drive which can permit the motor to be driven. Therefore it is

not necessary to have a second channel to interrupt the power

connection, nor a fault detection circuit.

It is important to note that a single short-circuit from the Enable input

(STO) to a DC supply of approximately +24V would cause the drive to be

enabled. For this reason, Figure 6-47 shows the wire from the Enable

input to the safety relay as "protected wiring" so that the possibility of a

short circuit from this wire to the DC supply can be excluded, as

specified in ISO 13849-2. The wiring can be protected by placing it in a

segregated cable duct or other enclosure, or by providing it with a

grounded shield. The shield is provided to avoid a hazard from an

electrical fault. It may be grounded by any convenient method, no

special EMC precautions are required.

If the use of protected wiring is not acceptable, so that the possibility of

this short circuit must be allowed for, then a relay must be used to

monitor the state of the Enable input, together with a single safety

contactor to prevent operation of the motor after a fault. This is illustrated

in Figure 6-48.

N

The auxiliary relay K2 must be located in the same enclosure and close

to the drive, with its coil connected as closely as possible to the drive

enable (STO) input.

Figure 6-48 Use of contactor and relay to avoid the need for

protected wiring

For further applications guidance, refer to the Unidrive SP Advanced

User Guide.

Stop

Start

Drive

Enable

K1

(or at

drive

output)

K1

+24V

~

K1

Drive

STO

M

Using contactor

Using SAFE TORQUE OFF

(SECURE DISABLE)

T31

T31

3 ~

Stop

Start

K1

+24V

K1

Stop

Start

Drive

Enable

K1

K2

+24V

Safety

relay

Two-channel

interlocks

Reset

K1

K2

K1

K2

K1 K2

M

3 ~

STO

+24V

Safety

relay

Interlocks

Reset

(Pr )

10.02

Protected wiring

(screened or

segregated)

SD

K1

K2

+24V

Safety

relay

Two-channel

interlocks

Reset

K1

K2

K1 K2

Loading...

Loading...